stainless steel wholesale

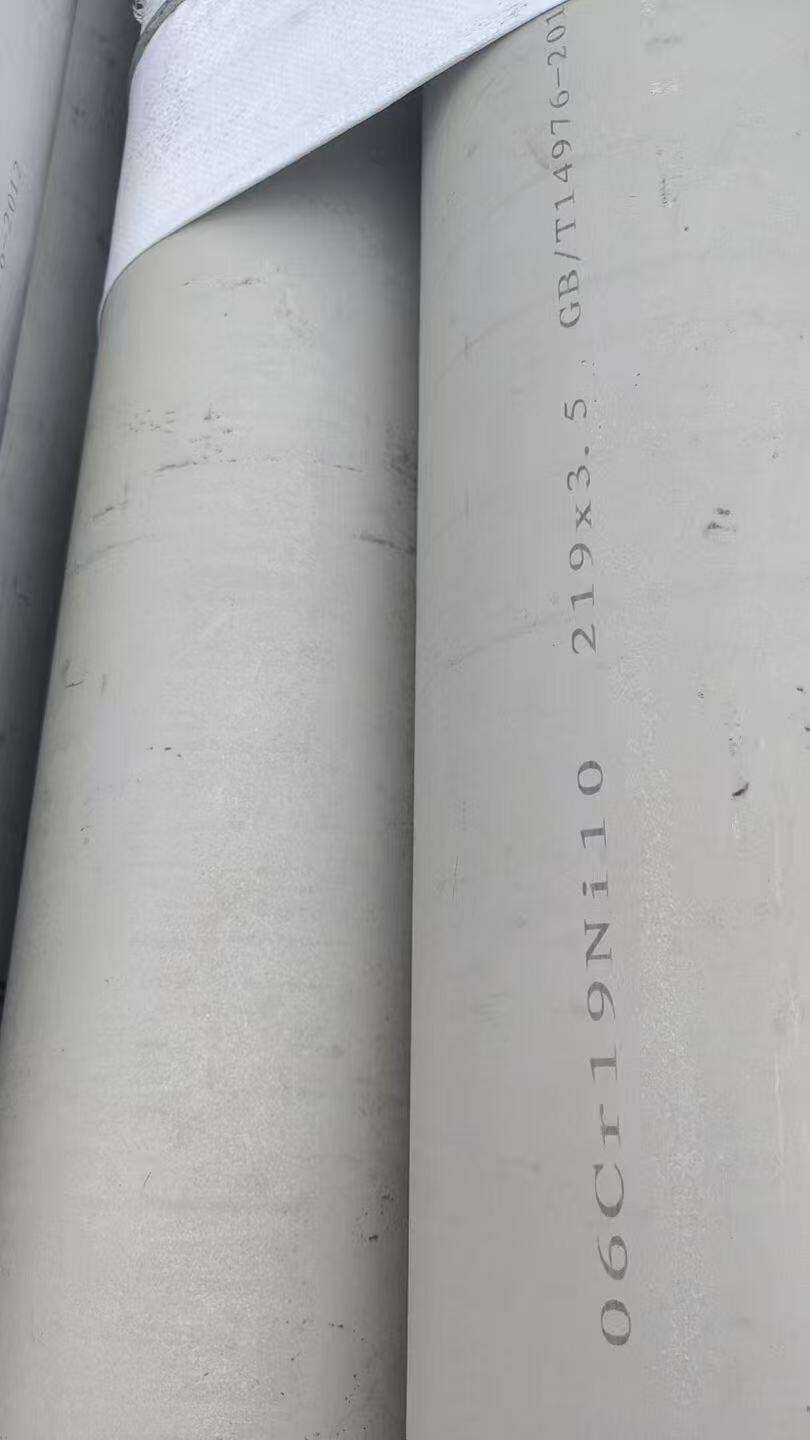

Stainless steel wholesale represents a critical component in modern industrial supply chains, serving as the backbone for numerous manufacturing sectors worldwide. This comprehensive distribution system encompasses the bulk procurement, storage, and redistribution of various stainless steel products, including sheets, plates, tubes, bars, coils, and specialized alloys. The stainless steel wholesale industry functions as an intermediary between large-scale steel producers and end-users, facilitating efficient market access while maintaining competitive pricing structures. The technological foundation of stainless steel wholesale operations relies heavily on advanced inventory management systems, automated warehousing solutions, and sophisticated logistics networks that ensure optimal product handling and delivery. These systems incorporate real-time tracking capabilities, quality control protocols, and temperature-controlled storage environments that preserve material integrity throughout the supply chain. The primary applications of stainless steel wholesale span across diverse industries including construction, automotive manufacturing, food processing, medical equipment production, chemical processing, and marine engineering. In construction applications, wholesale stainless steel provides structural components, architectural elements, and finishing materials that offer superior durability and aesthetic appeal. The automotive sector utilizes wholesale stainless steel for exhaust systems, decorative trim, and performance components that require corrosion resistance and high-temperature stability. Food processing industries depend on wholesale stainless steel for equipment manufacturing, storage tanks, and processing machinery that meets stringent hygiene standards. Medical device manufacturers rely on specialized grades of wholesale stainless steel for surgical instruments, implants, and diagnostic equipment that demand biocompatibility and precision engineering. The technological features of modern stainless steel wholesale operations include advanced metallurgical testing equipment, automated cutting and processing capabilities, and integrated quality assurance systems that ensure consistent product specifications and compliance with international standards.