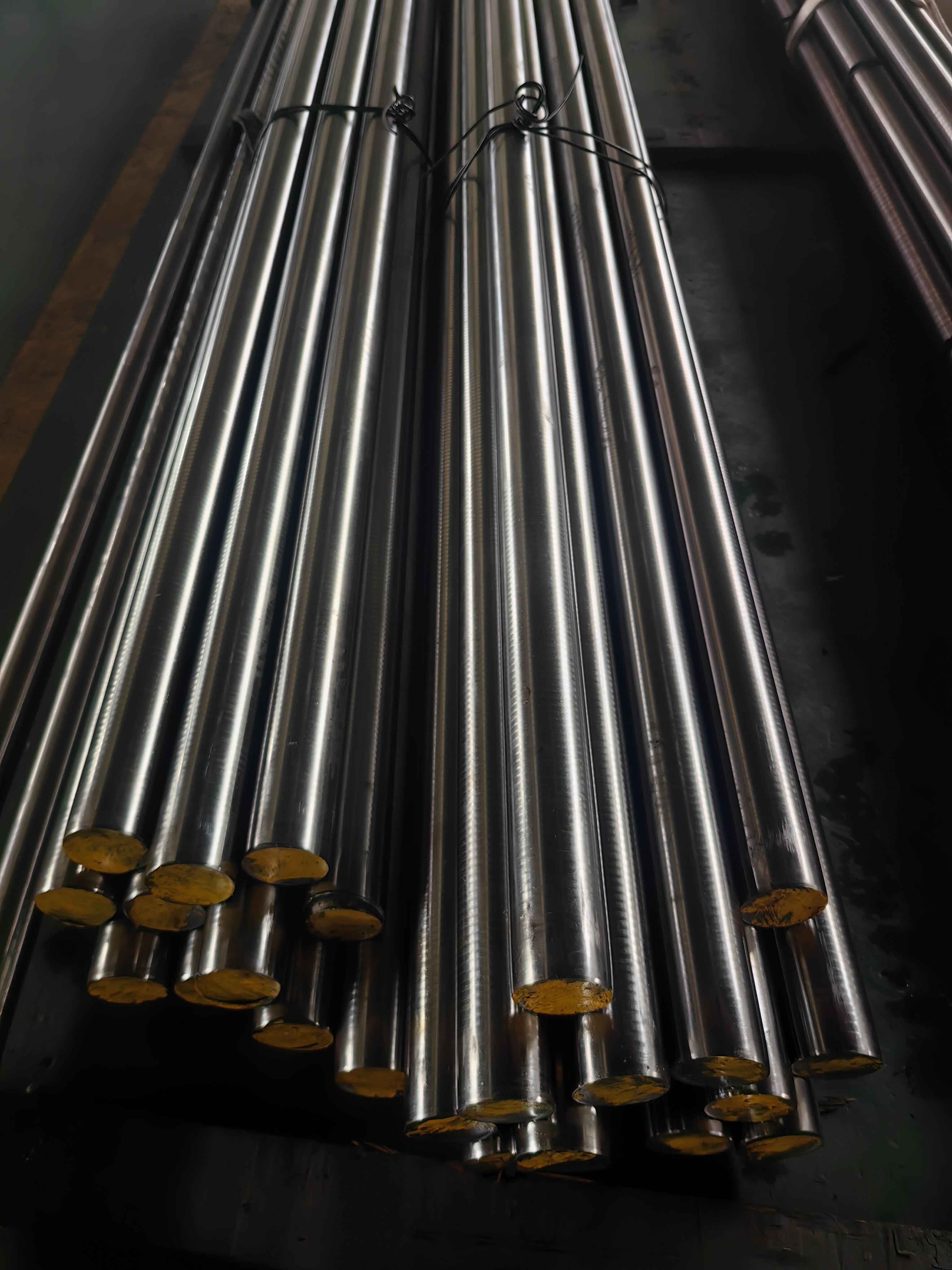

قوة ومتانة الفولاذ السبائكي

ما هو الفولاذ السبائكي؟ يُعد الفولاذ السبائكي، الذي يُستخدم على نطاق واسع في مختلف التطبيقات الصناعية، أساسًا مزيجًا من الحديد مُعزز بعناصر رئيسية مثل الكربون والمنغنيز والكروم والنيكل. ولكل من هذه العناصر دور محدد في تعزيز...

عرض المزيد