perforated weathering steel

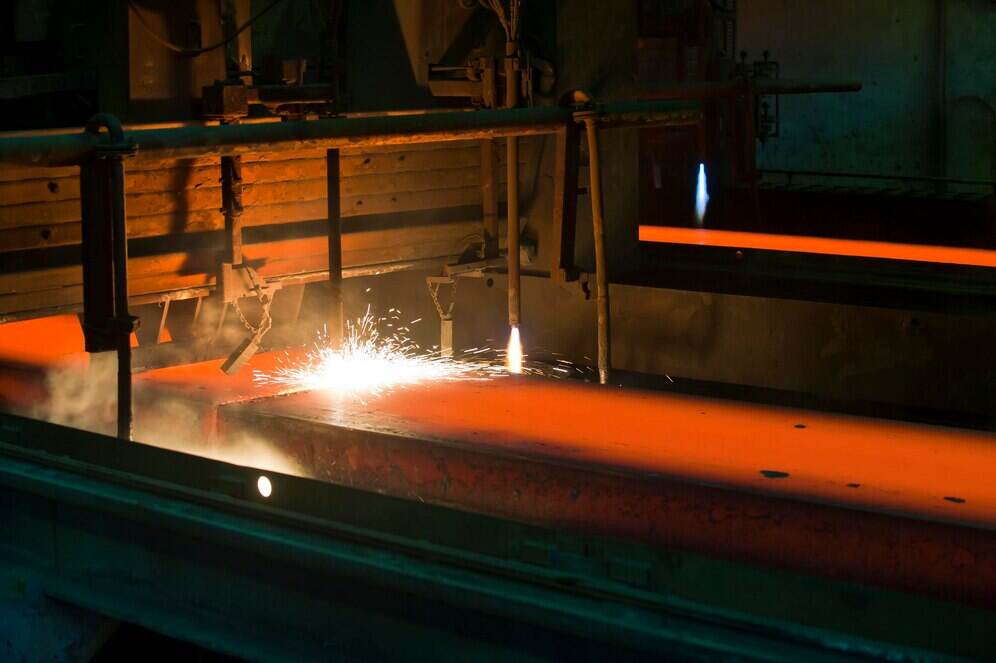

Perforated weathering steel represents a revolutionary advancement in architectural and industrial materials, combining the natural weathering properties of corten steel with strategically designed perforations. This innovative material develops a protective rust-like patina over time, creating a distinctive aesthetic while providing exceptional durability and corrosion resistance. The perforations serve multiple functional purposes, including weight reduction, enhanced airflow, improved drainage, and unique visual effects through light and shadow play. Technologically, perforated weathering steel utilizes precise manufacturing processes to create holes of varying sizes, patterns, and densities according to specific project requirements. The steel composition typically includes copper, chromium, nickel, and phosphorus, which form the characteristic protective oxide layer that prevents further corrosion penetration. Manufacturing involves computer-controlled punching, laser cutting, or plasma cutting techniques to achieve exact perforation specifications. The weathering process occurs naturally through exposure to atmospheric conditions, eliminating the need for traditional protective coatings and reducing long-term maintenance requirements. Applications span diverse industries including architectural facades, screening panels, decorative elements, industrial filtration systems, acoustic barriers, ventilation components, and landscape features. In construction projects, perforated weathering steel serves as both functional and aesthetic elements, providing structural support while creating visually appealing surfaces. The material's versatility allows for custom perforation patterns ranging from simple circular holes to complex geometric designs, enabling architects and designers to achieve specific performance criteria and visual outcomes. Environmental benefits include recyclability, reduced maintenance needs, and elimination of volatile organic compounds typically associated with painted steel surfaces.