weathering steel

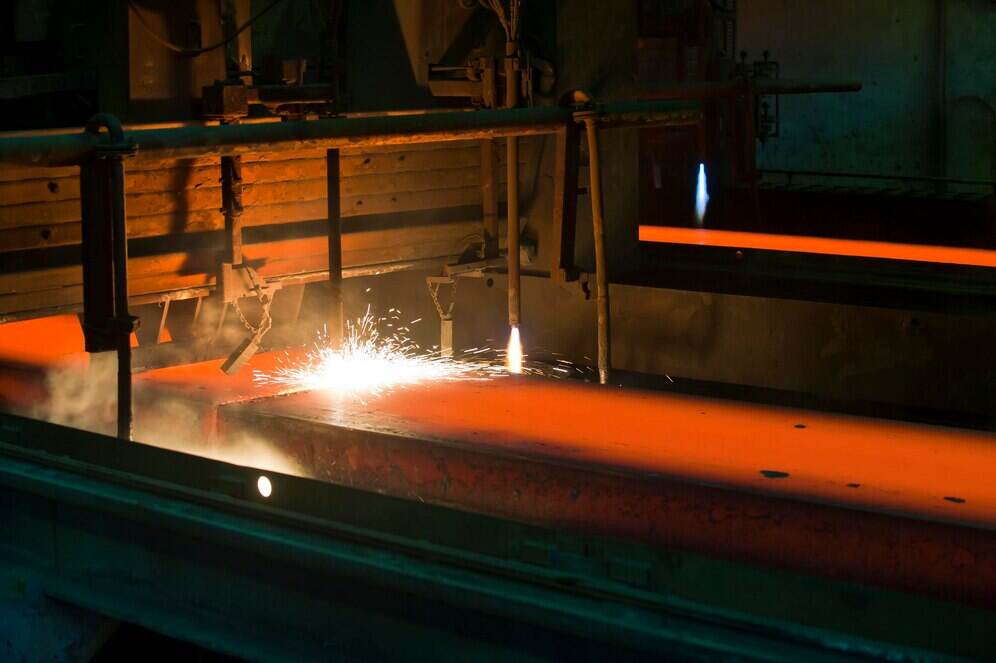

Weathering steel represents a revolutionary advancement in construction materials, offering exceptional durability and aesthetic appeal for modern architectural projects. This specialized alloy contains carefully controlled amounts of copper, chromium, nickel, and phosphorus, which create a protective patina layer when exposed to atmospheric conditions. The weathering steel develops this distinctive rust-colored surface that acts as a natural barrier against further corrosion, eliminating the need for traditional protective coatings or regular maintenance painting. The technological innovation behind weathering steel lies in its self-healing properties, where the oxidation process forms a dense, adherent oxide layer that continuously regenerates itself over time. This remarkable material maintains structural integrity while developing its characteristic appearance, making it ideal for bridges, building facades, sculptures, and outdoor structures. The weathering steel demonstrates superior performance in various climate conditions, from coastal environments with high salt exposure to industrial areas with atmospheric pollutants. Engineers and architects increasingly specify weathering steel for projects requiring long-term reliability and minimal maintenance requirements. The material exhibits excellent mechanical properties, including high tensile strength and fatigue resistance, ensuring structural safety throughout its extended service life. Installation of weathering steel requires specific expertise to manage the initial weathering process effectively, but once established, the protective patina provides decades of reliable performance. The environmental benefits of weathering steel include reduced maintenance interventions, elimination of coating waste, and extended structure lifespan, contributing to sustainable construction practices.