weathering steel manufacturer

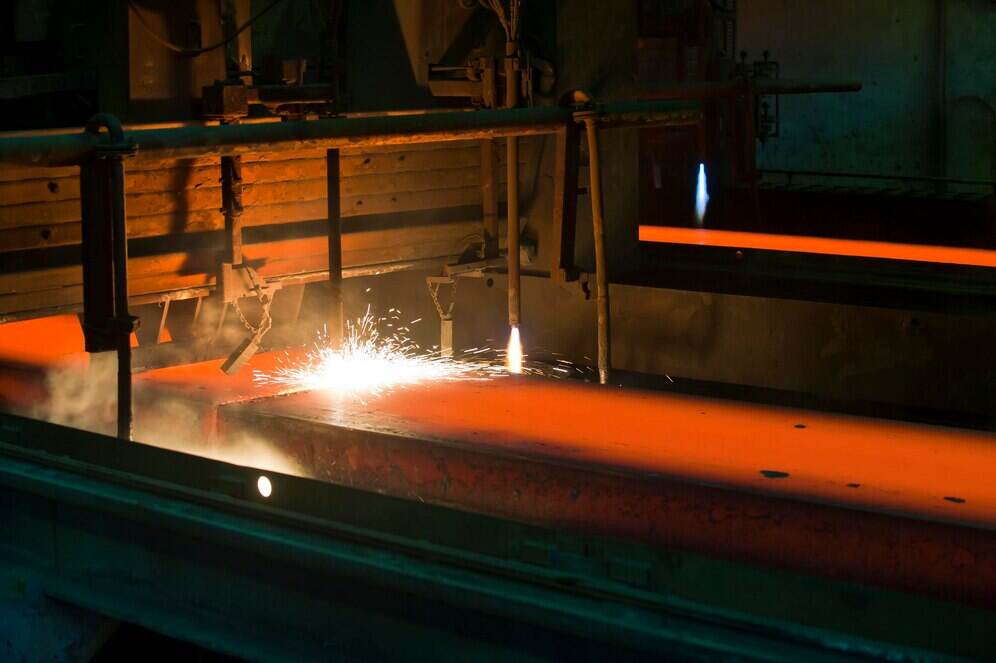

A weathering steel manufacturer specializes in producing high-grade atmospheric corrosion-resistant steel alloys that develop a protective rust layer when exposed to natural elements. These specialized producers utilize advanced metallurgical processes to create steel compositions containing copper, chromium, nickel, and phosphorus elements that enhance corrosion resistance properties. The weathering steel manufacturer operates sophisticated production facilities equipped with electric arc furnaces, continuous casting systems, and precision rolling mills to ensure consistent material quality and dimensional accuracy. The primary function of a weathering steel manufacturer involves controlling chemical composition through precise alloying techniques, maintaining strict quality standards throughout the production process, and delivering products that meet international specifications such as ASTM A588, EN 10025, and JIS G3114. Technological features employed by modern weathering steel manufacturers include computer-controlled melting processes, automated quality testing systems, and advanced heat treatment methods that optimize the steel's weathering characteristics. These manufacturers typically offer various product forms including plates, sheets, structural beams, angles, channels, and custom-fabricated components to serve diverse industrial applications. The weathering steel manufacturer serves multiple sectors including construction, transportation infrastructure, architectural design, marine applications, and industrial equipment manufacturing. Bridge construction represents a significant application area where weathering steel manufacturers provide materials for highway overpasses, railway bridges, and pedestrian walkways. Architectural applications include building facades, sculptural elements, outdoor furniture, and landscaping features where the natural patina appearance adds aesthetic value. The manufacturing process involves careful selection of raw materials, precise temperature control during melting and casting, controlled cooling rates, and comprehensive testing procedures to verify mechanical properties and corrosion resistance performance. Quality assurance protocols implemented by reputable weathering steel manufacturers include chemical analysis, tensile testing, impact testing, bend testing, and accelerated weathering tests to ensure product reliability and longevity in outdoor environments.