self weathering steel

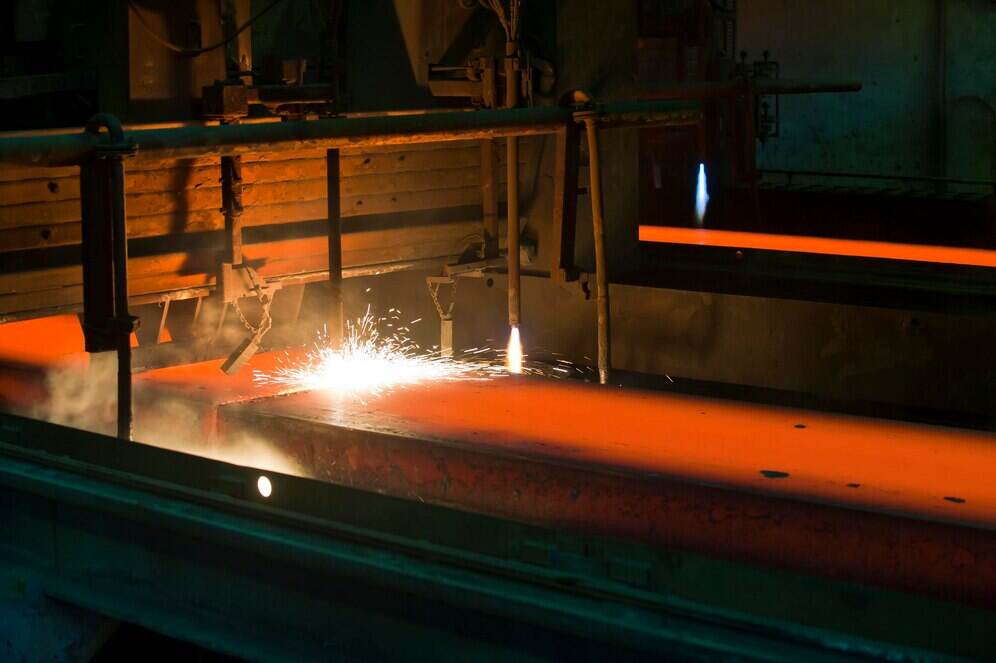

Self weathering steel represents a revolutionary advancement in metallurgy, designed to develop a protective rust layer that shields the underlying metal from further corrosion. This innovative material, also known as atmospheric corrosion resistant steel, forms a stable oxide coating when exposed to natural weather conditions. The self weathering steel contains specific alloying elements including copper, chromium, nickel, and phosphorus, which work together to create a dense, adherent patina that prevents deeper penetration of moisture and oxygen. The formation process typically takes two to five years, during which the surface develops its characteristic rust-colored appearance. This protective layer continuously regenerates itself, providing long-term durability without the need for traditional paint coatings or maintenance treatments. The technology behind self weathering steel emerged from extensive research into atmospheric corrosion mechanisms and the development of specialized alloy compositions. Manufacturing processes involve precise control of chemical composition and heat treatment to optimize the formation of the protective oxide layer. The steel maintains its structural integrity while developing enhanced resistance to environmental factors including rain, humidity, temperature fluctuations, and urban pollutants. Applications span across architectural projects, infrastructure development, transportation systems, and industrial facilities where durability and aesthetic appeal are paramount. The unique properties of self weathering steel make it particularly suitable for outdoor structures, bridges, building facades, sculptures, and marine environments. Its ability to combine structural strength with natural weather protection has made it increasingly popular among architects, engineers, and construction professionals seeking sustainable and cost-effective solutions for long-term projects.