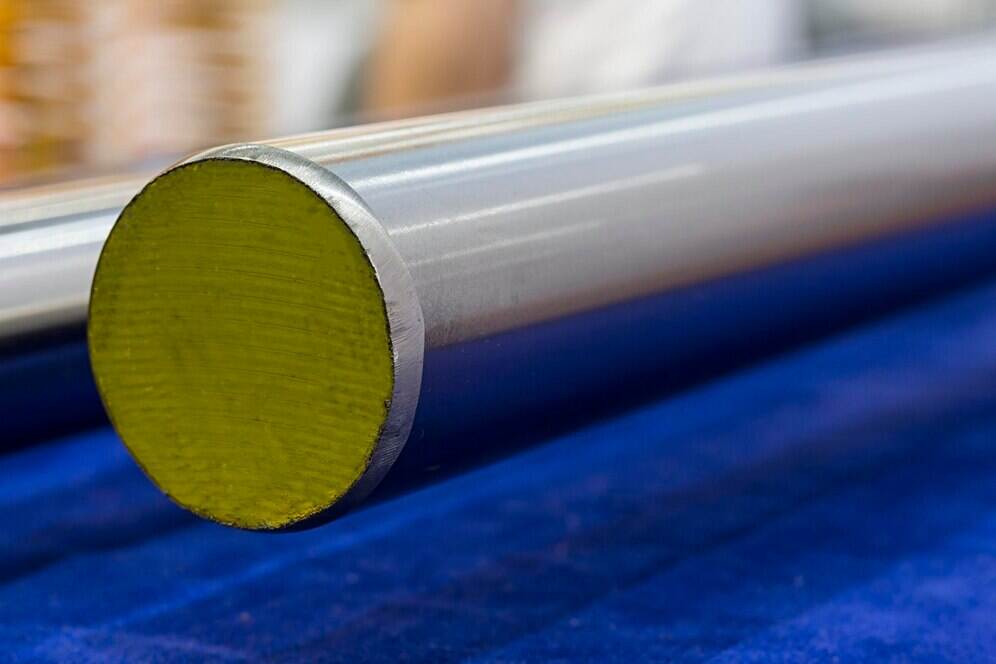

steel bar factory

A steel bar factory represents a cornerstone of modern industrial manufacturing, serving as a specialized facility designed to produce high-quality steel reinforcement bars essential for construction and infrastructure projects worldwide. These sophisticated manufacturing plants combine advanced metallurgical processes with cutting-edge technology to transform raw steel materials into precisely engineered reinforcement products that meet stringent international standards. The primary function of a steel bar factory revolves around the systematic production of ribbed steel bars, commonly known as rebar, which provide crucial structural support in concrete construction applications. The manufacturing process begins with carefully selected raw materials, including steel billets or scrap metal, which undergo rigorous quality testing before entering the production line. Modern steel bar factory operations employ electric arc furnaces or induction furnaces to melt and refine the steel, ensuring optimal chemical composition and mechanical properties. The molten steel then passes through continuous casting systems that form it into billets of predetermined dimensions. These billets subsequently enter the rolling mill section, where they are heated in reheat furnaces and passed through a series of rolling stands that gradually reduce their cross-sectional area while increasing their length. The rolling process also creates the characteristic ribbed surface pattern that enhances the bond between steel and concrete in construction applications. Quality control systems integrated throughout the steel bar factory monitor temperature, chemical composition, dimensional accuracy, and mechanical properties at every stage of production. Advanced computer-controlled systems ensure consistent product quality while optimizing energy consumption and production efficiency. The final products undergo comprehensive testing, including tensile strength, yield strength, and elongation measurements, before being bundled, tagged, and prepared for shipment to construction sites, distributors, and retailers across various markets.