tool steel vendors

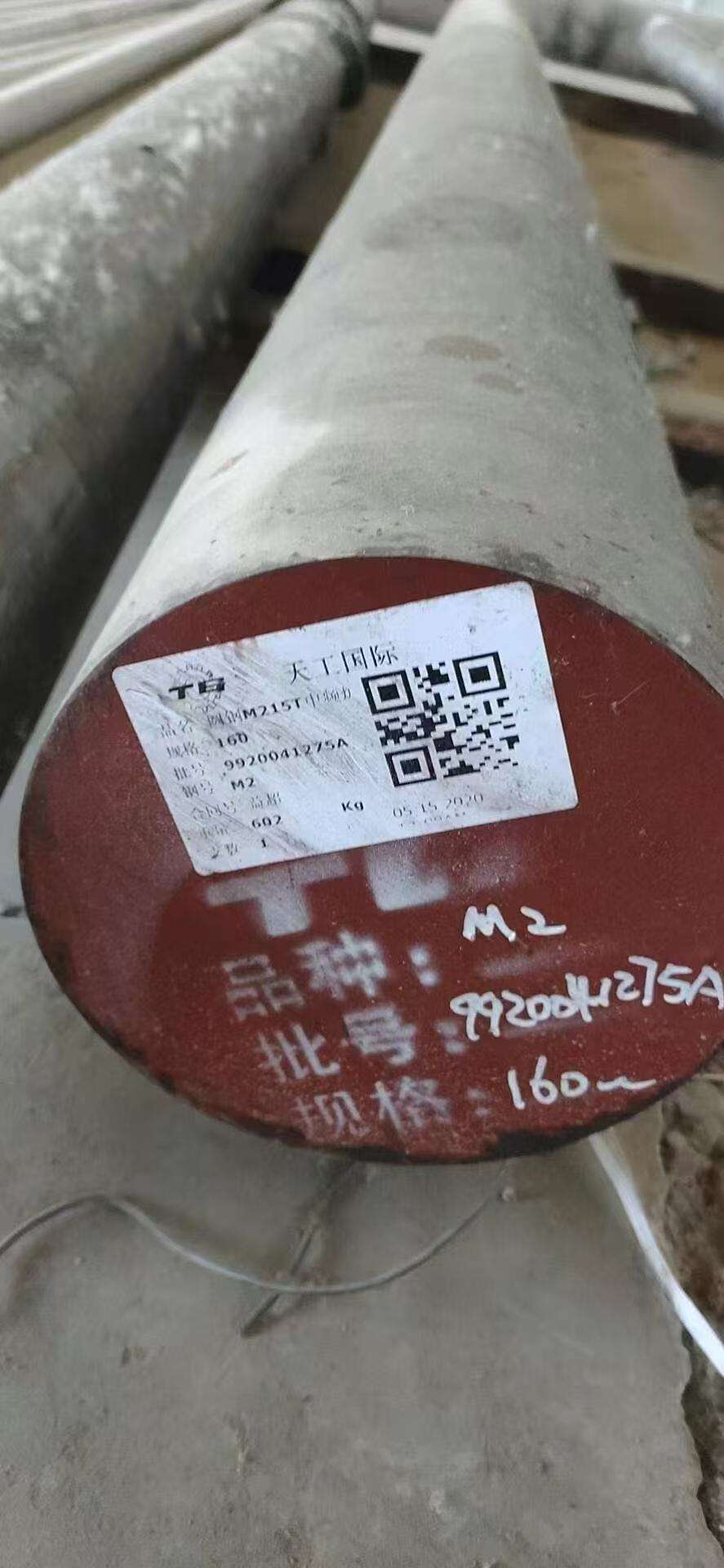

Tool steel vendors serve as critical partners in the manufacturing ecosystem, providing specialized high-performance steel alloys designed to withstand extreme conditions in tooling applications. These vendors supply essential materials that form the backbone of modern manufacturing processes across automotive, aerospace, construction, and precision machining industries. Tool steel vendors maintain extensive inventories of various steel grades including hot work steels, cold work steels, high-speed steels, and shock-resistant varieties. Their primary function involves sourcing, processing, and distributing these specialized materials while ensuring consistent quality standards and chemical compositions. Modern tool steel vendors employ sophisticated quality control systems that include spectrometric analysis, hardness testing, and dimensional verification to guarantee material integrity. These suppliers work closely with heat treatment facilities to provide value-added services such as annealing, stress relieving, and custom machining. Tool steel vendors typically maintain relationships with major steel mills worldwide, enabling them to offer competitive pricing and reliable supply chains. Their technological capabilities extend beyond simple distribution to include technical consultation services where metallurgical experts help customers select appropriate grades for specific applications. Many vendors utilize advanced inventory management systems that track material certifications, mill test reports, and lot traceability information. The geographic distribution network of tool steel vendors ensures rapid delivery to manufacturing facilities while minimizing transportation costs and lead times. These vendors often specialize in particular market segments, developing deep expertise in specific applications such as plastic injection molding, metal stamping, or cutting tool manufacturing. Their warehouses typically feature climate-controlled environments to prevent material degradation and maintain optimal storage conditions. Tool steel vendors frequently invest in processing equipment including precision cutting, surface grinding, and heat treatment capabilities to offer finished products ready for immediate use.