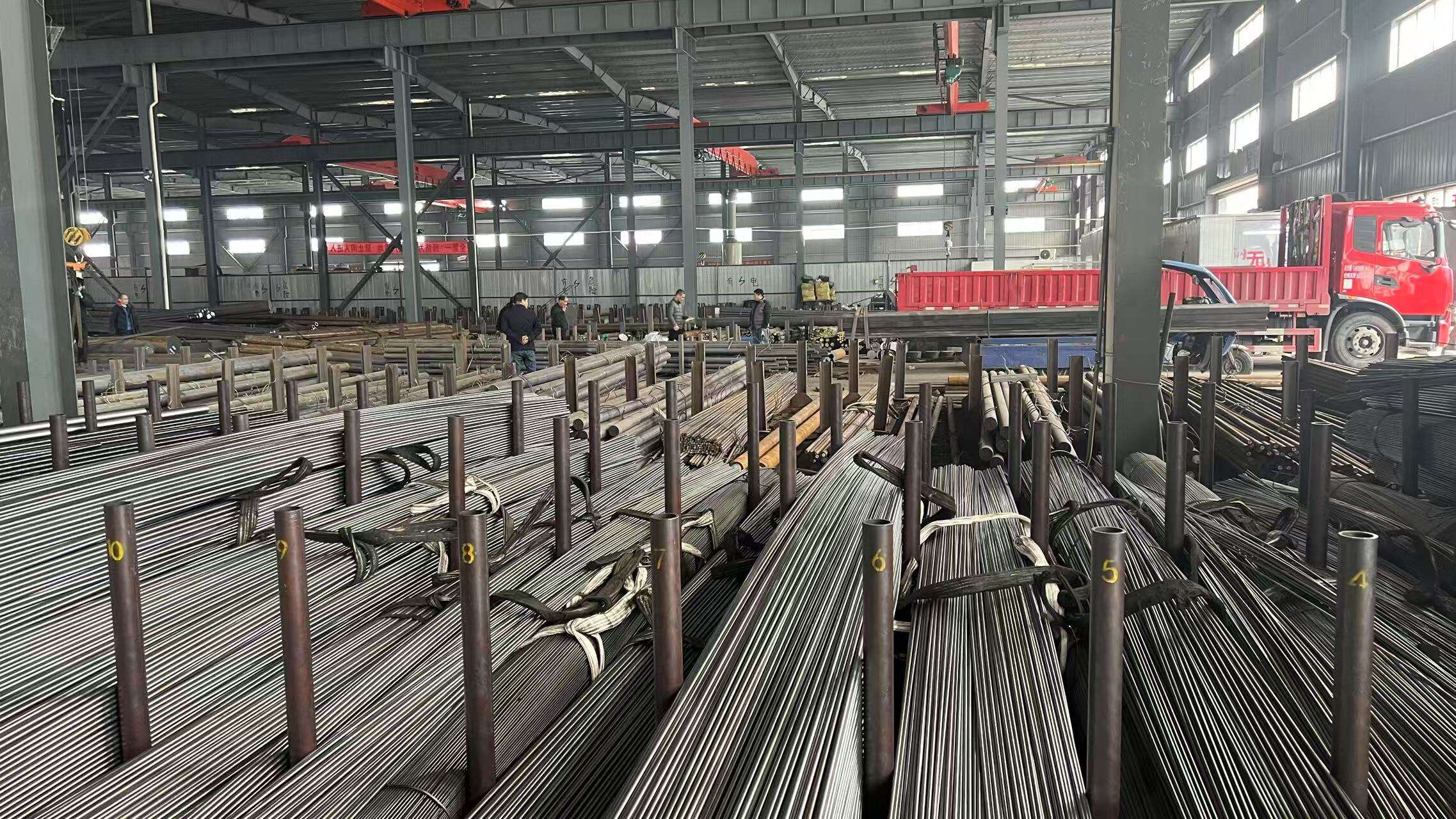

concrete steel bar

Concrete steel bar, commonly known as rebar, represents a fundamental component in modern construction and infrastructure development. This reinforcing steel material consists of carbon steel bars with ribbed surfaces designed to enhance bonding strength with concrete materials. The concrete steel bar serves as the backbone of reinforced concrete structures, providing tensile strength where concrete naturally lacks resistance. Manufacturing processes involve hot rolling techniques that create deformed surfaces with ribs, lugs, and indentations that mechanically interlock with surrounding concrete. The primary function of concrete steel bar centers on compensating for concrete's weakness in tension while maintaining structural integrity under various load conditions. These bars typically range from 6mm to 40mm in diameter, accommodating diverse construction requirements from residential foundations to massive infrastructure projects. The steel composition includes carefully controlled carbon content, manganese, silicon, and other alloying elements that optimize strength and ductility characteristics. Surface deformations follow international standards ensuring consistent performance across different manufacturers and regions. Technological features include precise dimensional tolerances, controlled chemical composition, and standardized mechanical properties that meet rigorous engineering specifications. The concrete steel bar exhibits excellent weldability, allowing for efficient field connections and custom fabrication requirements. Corrosion resistance can be enhanced through epoxy coating, galvanization, or stainless steel variants for aggressive environmental conditions. Applications span residential construction, commercial buildings, bridges, tunnels, dams, nuclear facilities, and marine structures. Quality control measures during production include tensile testing, bend testing, and chemical analysis to ensure compliance with national and international standards. Modern concrete steel bar production incorporates sustainable practices including recycled steel content and energy-efficient manufacturing processes, supporting environmental responsibility in construction projects.