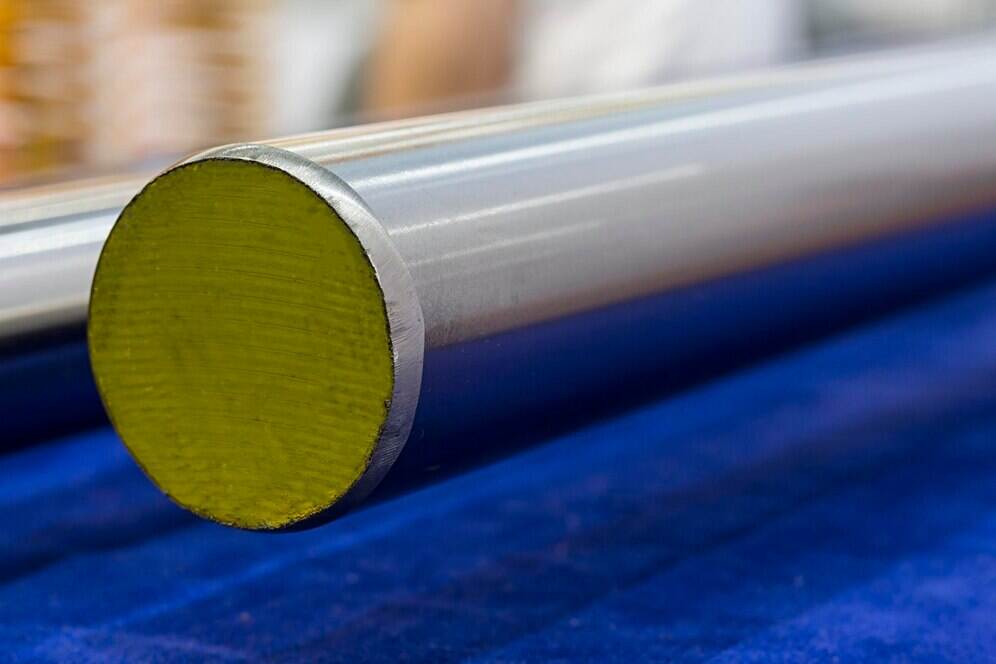

steel bar bending

Steel bar bending represents a fundamental metalworking process that transforms straight reinforcement bars into precisely shaped components essential for construction and manufacturing projects. This sophisticated technique involves the controlled deformation of steel reinforcement bars using specialized equipment and methodologies to achieve exact angular configurations, curves, and geometric patterns required by engineering specifications. The steel bar bending process encompasses multiple operational phases including measurement, marking, positioning, and the actual bending procedure, each demanding meticulous attention to detail and adherence to structural engineering standards. Modern steel bar bending operations utilize advanced machinery equipped with programmable controls, hydraulic systems, and precision measurement tools that ensure consistent results across large-scale production runs. The technological infrastructure supporting steel bar bending has evolved significantly, incorporating computer-aided design integration, automated feeding mechanisms, and quality control systems that monitor dimensional accuracy throughout the entire bending cycle. Steel bar bending serves critical functions in reinforced concrete construction, providing the shaped reinforcement elements that enhance structural integrity and load-bearing capacity. The process accommodates various steel grades and diameters, from lightweight residential applications to heavy-duty industrial installations requiring robust reinforcement solutions. Quality steel bar bending operations maintain strict compliance with international construction codes and safety standards, ensuring that bent reinforcement bars meet or exceed specified tensile strength requirements and dimensional tolerances. The versatility of steel bar bending enables the production of complex reinforcement configurations including stirrups, ties, hooks, and custom geometric shapes that facilitate proper concrete placement and structural performance optimization.