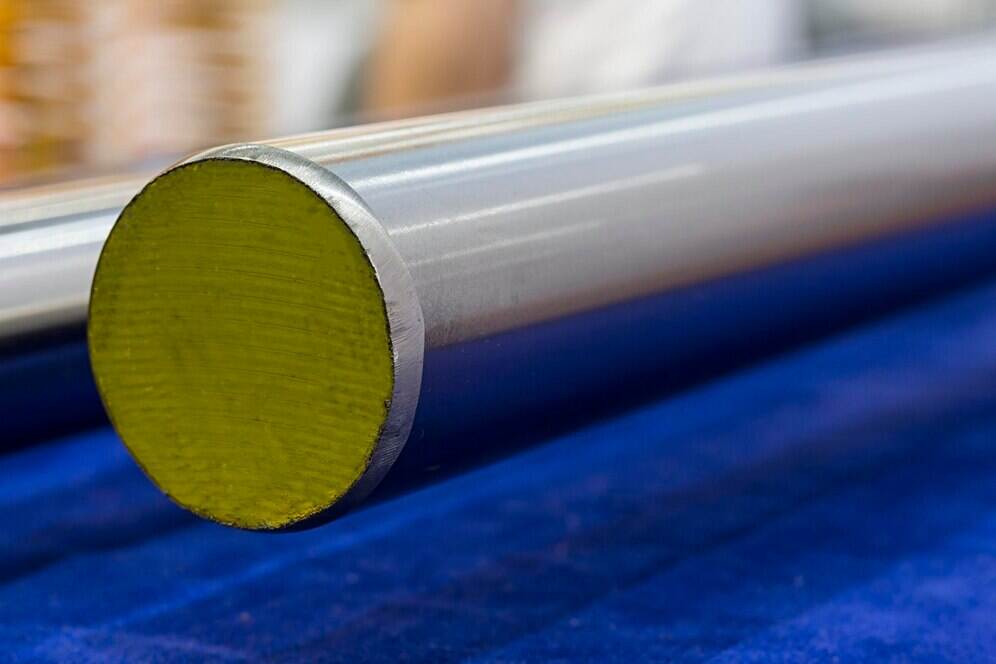

steel bar manufacturer

A steel bar manufacturer represents a specialized industrial enterprise that produces reinforced steel bars, also known as rebar, through sophisticated metallurgical processes. These companies operate comprehensive production facilities equipped with advanced furnaces, rolling mills, and quality control systems to transform raw materials into high-strength construction components. The primary function of a steel bar manufacturer involves melting scrap metal or iron ore in electric arc furnaces, followed by continuous casting and hot rolling processes that shape the material into various bar configurations. Modern steel bar manufacturer facilities incorporate automated systems that monitor temperature, chemical composition, and dimensional accuracy throughout production cycles. The technological features of contemporary steel bar manufacturer operations include computerized process control, automated material handling systems, and real-time quality monitoring equipment. These manufacturers utilize sophisticated testing laboratories that verify tensile strength, yield strength, elongation properties, and chemical composition to ensure compliance with international standards such as ASTM, BS, and IS specifications. Applications for steel bar manufacturer products span residential construction, commercial building projects, infrastructure development, and industrial facilities. Construction companies rely on steel bar manufacturer products for reinforcing concrete structures, creating foundations, building frameworks, and enhancing structural integrity. The versatility of steel bar manufacturer offerings includes various grades, diameters, and lengths to accommodate diverse engineering requirements. Bridge construction, highway projects, and high-rise buildings depend heavily on steel bar manufacturer products for their structural reinforcement needs. Additionally, precast concrete manufacturers source materials from steel bar manufacturer companies to produce specialized building components. The quality assurance protocols implemented by reputable steel bar manufacturer organizations ensure consistent product performance and regulatory compliance across all manufacturing batches.