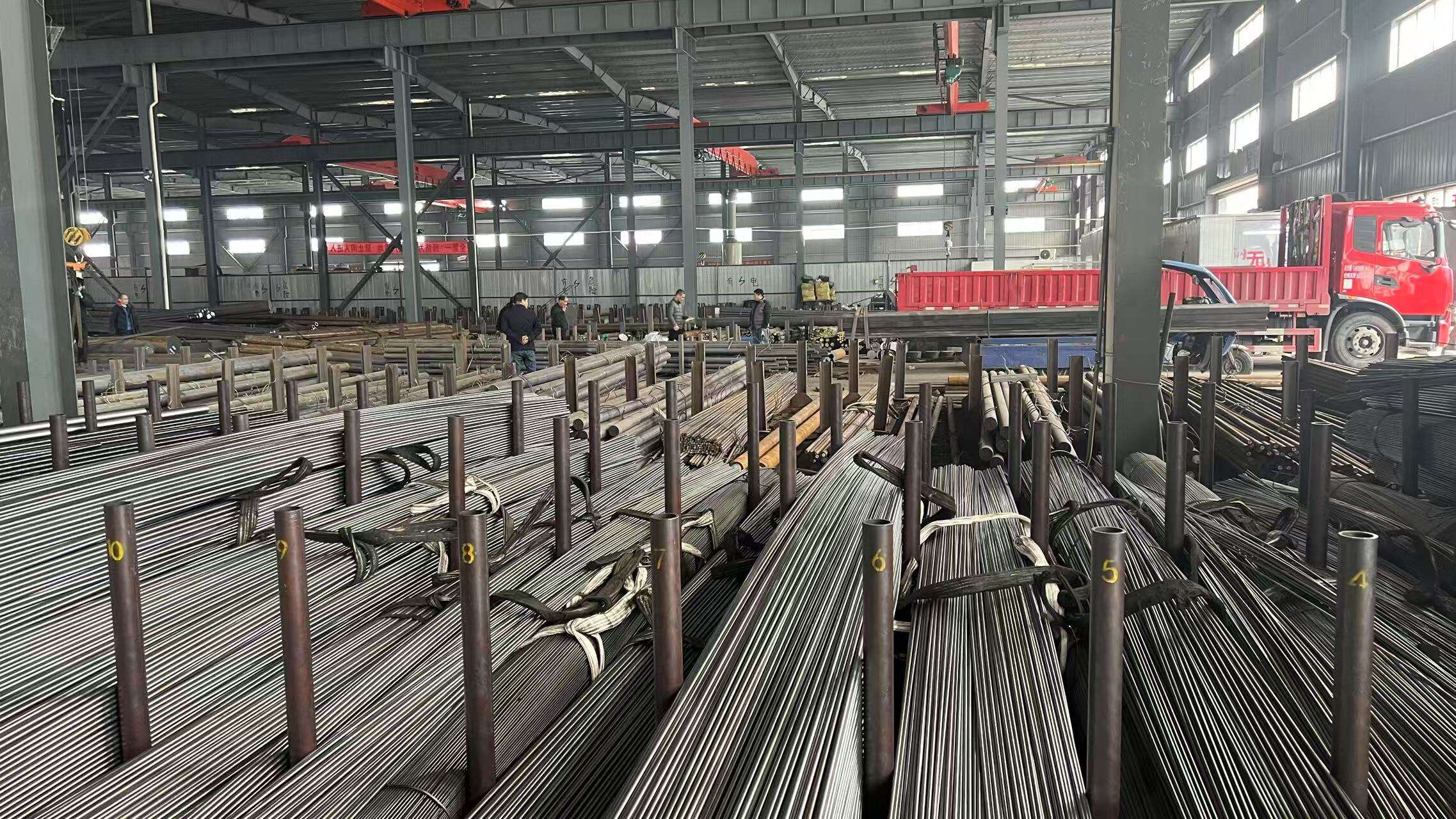

the steel bar

The steel bar stands as one of the most versatile and essential construction materials in modern engineering and architecture. This fundamental component serves as the backbone of countless structures, from residential buildings to massive infrastructure projects. The steel bar, manufactured through precision rolling and forming processes, delivers exceptional structural integrity and load-bearing capabilities that make it indispensable across multiple industries. Its primary functions encompass reinforcement of concrete structures, provision of tensile strength in construction applications, and creation of robust frameworks for various engineering projects. The technological features of the steel bar include superior metallurgical properties achieved through controlled manufacturing processes. Advanced steel production techniques ensure consistent chemical composition, optimal carbon content, and precise dimensional accuracy. The surface characteristics of the steel bar feature ribbed or deformed patterns that enhance bonding capabilities with concrete and other materials. Heat treatment processes during manufacturing contribute to improved mechanical properties, including enhanced yield strength, ultimate tensile strength, and ductility. Modern steel bar production incorporates quality control measures that guarantee compliance with international standards and specifications. Applications of the steel bar span numerous sectors, including residential construction, commercial building projects, bridge construction, highway infrastructure, industrial facilities, and marine structures. In reinforced concrete construction, the steel bar provides essential tensile strength that concrete lacks naturally. This symbiotic relationship between steel and concrete creates composite materials with exceptional structural performance. The construction industry relies heavily on steel bars for foundation work, column reinforcement, beam construction, and slab applications. Infrastructure projects utilize steel bars for tunnel construction, retaining walls, and precast concrete elements. The versatility of the steel bar extends to specialized applications such as seismic retrofitting, where its ductility properties help structures withstand earthquake forces.