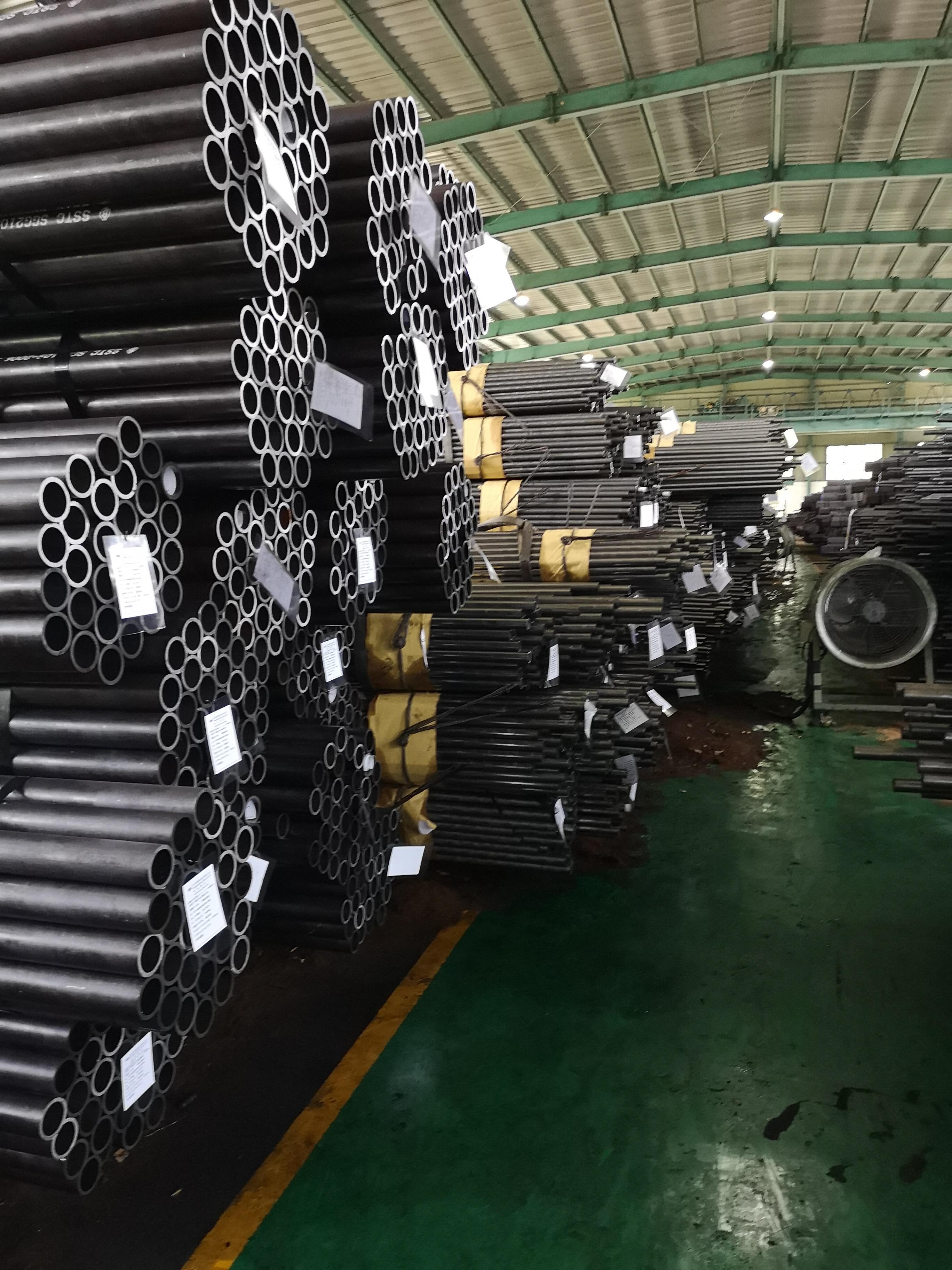

cr mo alloy steel

Cr mo alloy steel represents a sophisticated metallurgical achievement that combines chromium and molybdenum with carbon steel to create a material with exceptional mechanical properties. This advanced steel composition delivers superior performance across demanding industrial applications where standard carbon steel falls short. The cr mo alloy steel achieves its remarkable characteristics through precise alloying processes that optimize the interaction between chromium, molybdenum, and iron atoms within the crystal structure. Chromium content typically ranges from 0.5 to 9 percent, while molybdenum additions vary from 0.15 to 1 percent, creating a balanced composition that enhances both strength and corrosion resistance. The primary functions of cr mo alloy steel include providing exceptional tensile strength, improved hardenability, and enhanced resistance to environmental degradation. These steels maintain their structural integrity under extreme temperature fluctuations, making them ideal for high-stress applications. The technological features of cr mo alloy steel encompass refined grain structure, improved weldability, and excellent machinability compared to other high-strength alternatives. Manufacturing processes for cr mo alloy steel involve controlled heating, precise chemical composition management, and specialized heat treatment protocols that ensure consistent quality. Applications for this versatile material span multiple industries including automotive manufacturing, aerospace components, oil and gas exploration equipment, power generation systems, and heavy machinery construction. The petroleum industry relies heavily on cr mo alloy steel for pipeline construction, pressure vessels, and drilling equipment due to its ability to withstand corrosive environments and maintain structural stability under pressure. Power plants utilize cr mo alloy steel in boiler tubes, steam headers, and turbine components where high-temperature performance is critical. The automotive sector incorporates this material in transmission components, engine parts, and chassis elements that require superior fatigue resistance and dimensional stability.