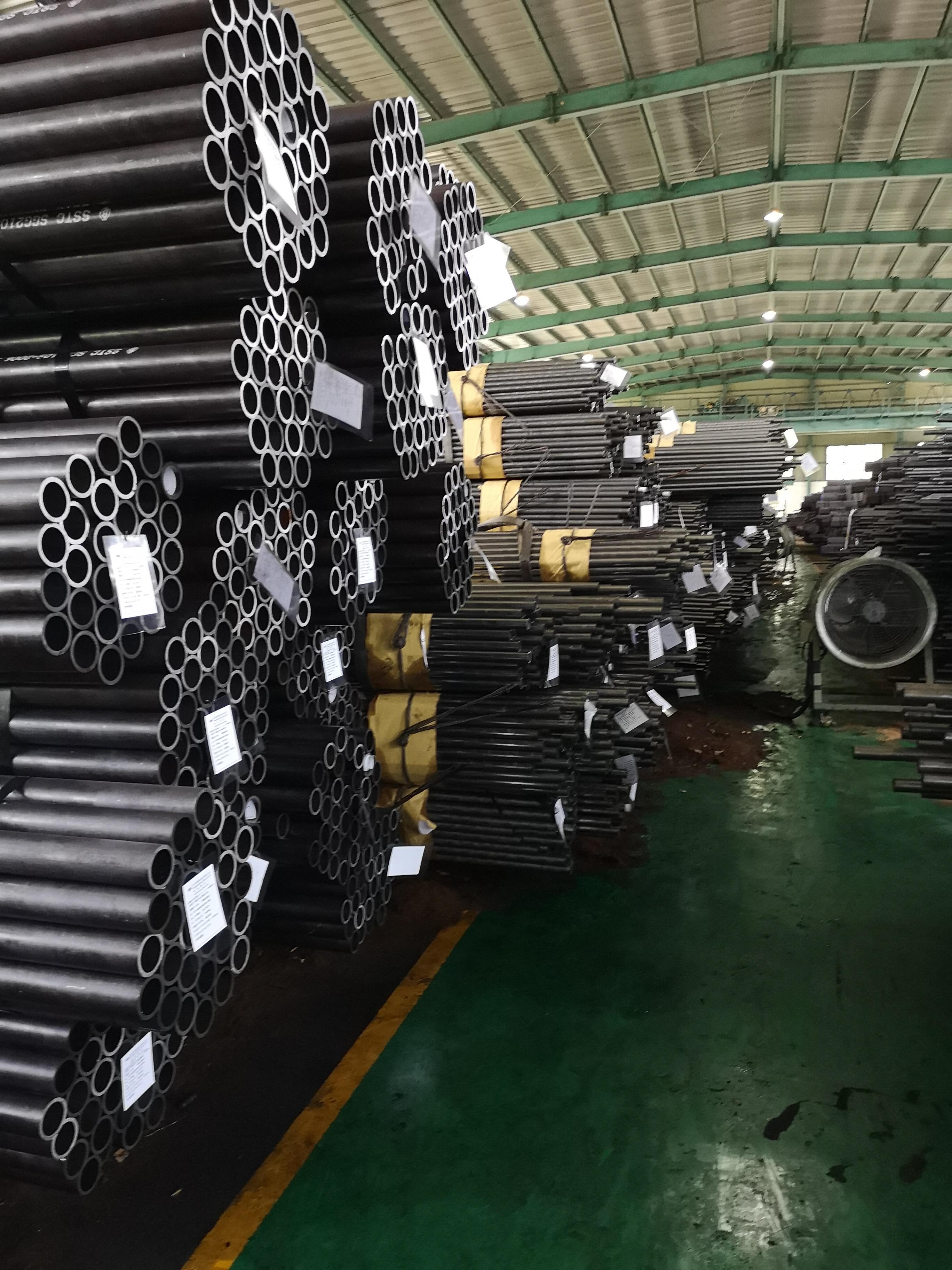

alloy steel 1.25 cr 0.5 mo

Alloy steel 1.25 cr 0.5 mo represents a sophisticated metallurgical achievement that combines chromium and molybdenum elements to create a high-performance material specifically engineered for demanding industrial applications. This specialized alloy steel 1.25 cr 0.5 mo composition contains 1.25 percent chromium and 0.5 percent molybdenum, which fundamentally transforms the base steel's mechanical properties and thermal characteristics. The primary functions of alloy steel 1.25 cr 0.5 mo revolve around its exceptional ability to maintain structural integrity under extreme temperature conditions, resist corrosion, and provide superior strength-to-weight ratios compared to conventional carbon steels. The technological features of this material include enhanced hardenability, improved toughness at elevated temperatures, and remarkable resistance to hydrogen embrittlement. These characteristics make alloy steel 1.25 cr 0.5 mo particularly valuable in power generation facilities, petrochemical processing plants, and high-temperature manufacturing environments. The chromium content in alloy steel 1.25 cr 0.5 mo significantly improves oxidation resistance and corrosion protection, while the molybdenum addition enhances the material's creep resistance and thermal stability. Applications for this versatile material span across multiple industries, including steam turbine components, pressure vessel construction, high-temperature piping systems, and critical structural elements in refineries. The unique metallurgical structure of alloy steel 1.25 cr 0.5 mo allows manufacturers to create components that operate safely at temperatures exceeding 500 degrees Celsius while maintaining dimensional stability and mechanical reliability. This material also demonstrates excellent weldability characteristics, making it suitable for complex fabrication processes and repair operations in industrial settings.