low alloy steel grades

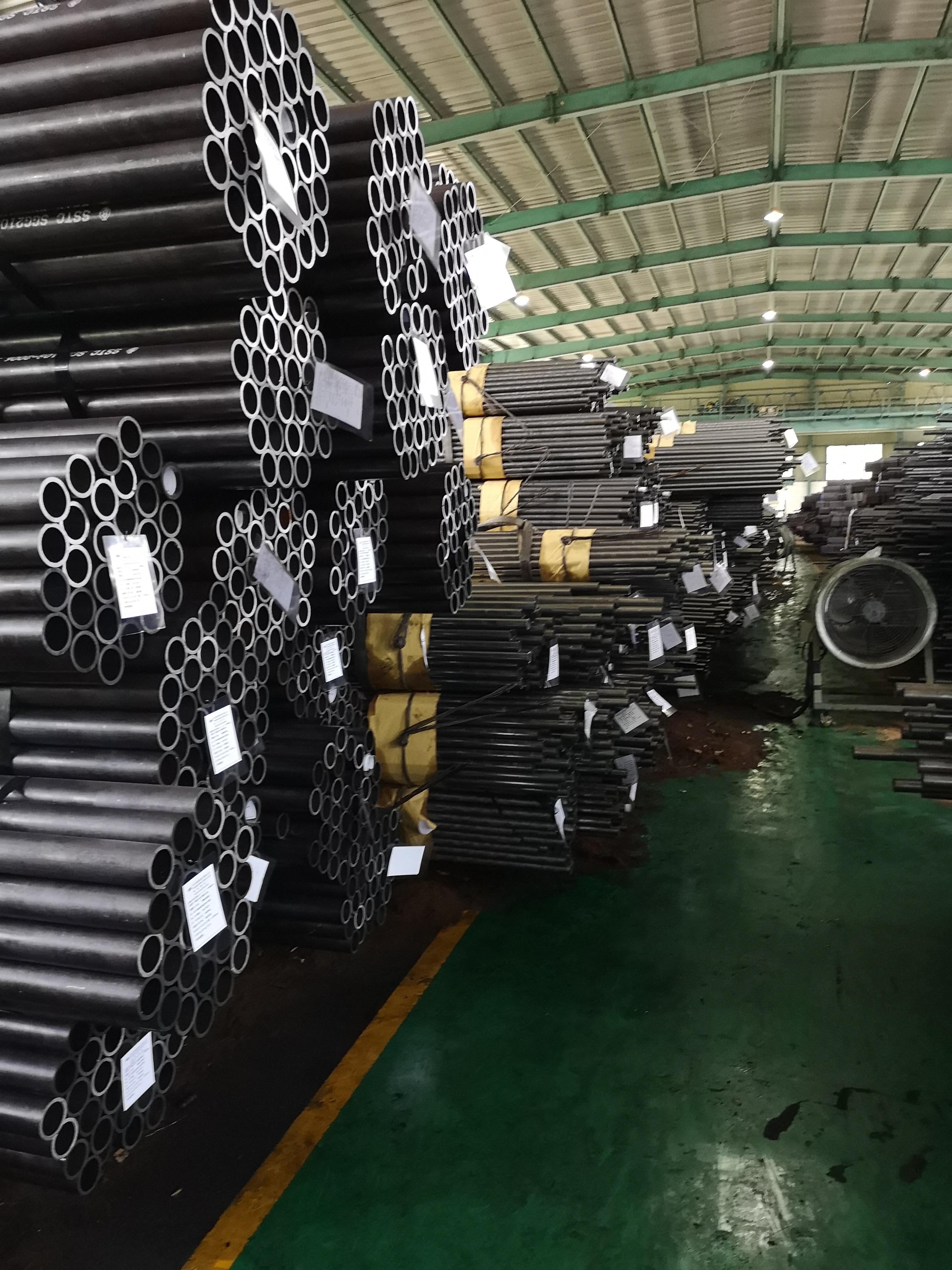

Low alloy steel grades represent a sophisticated category of metallic materials that contain small amounts of alloying elements, typically ranging from 1% to 5% by weight. These specialized steel compositions incorporate elements such as chromium, molybdenum, nickel, vanadium, and manganese to enhance specific properties while maintaining cost-effectiveness. The primary function of low alloy steel grades centers on providing superior mechanical properties compared to carbon steel, including increased strength, improved toughness, enhanced corrosion resistance, and better hardenability. The technological features of low alloy steel grades include fine-grain microstructure development, controlled precipitation hardening mechanisms, and optimized phase transformations during heat treatment processes. These materials demonstrate exceptional weldability characteristics, making them suitable for complex fabrication requirements in demanding industrial environments. Manufacturing processes for low alloy steel grades involve precise control of chemical composition, controlled rolling techniques, and specialized heat treatment procedures to achieve desired mechanical properties. The applications of low alloy steel grades span numerous industries including automotive manufacturing, construction engineering, oil and gas exploration, power generation facilities, and aerospace components. In automotive applications, these materials contribute to lightweight vehicle designs while maintaining structural integrity and crash safety standards. Construction projects benefit from the high strength-to-weight ratio of low alloy steel grades, enabling architects to design more efficient structural frameworks. The oil and gas industry relies heavily on these materials for pipeline construction, drilling equipment, and pressure vessel manufacturing due to their excellent resistance to hydrogen embrittlement and sulfide stress cracking. Power generation facilities utilize low alloy steel grades in turbine components, boiler construction, and steam piping systems where elevated temperature performance becomes critical. The versatility of low alloy steel grades extends to marine applications, where corrosion resistance and structural durability prove essential for shipbuilding and offshore platform construction.