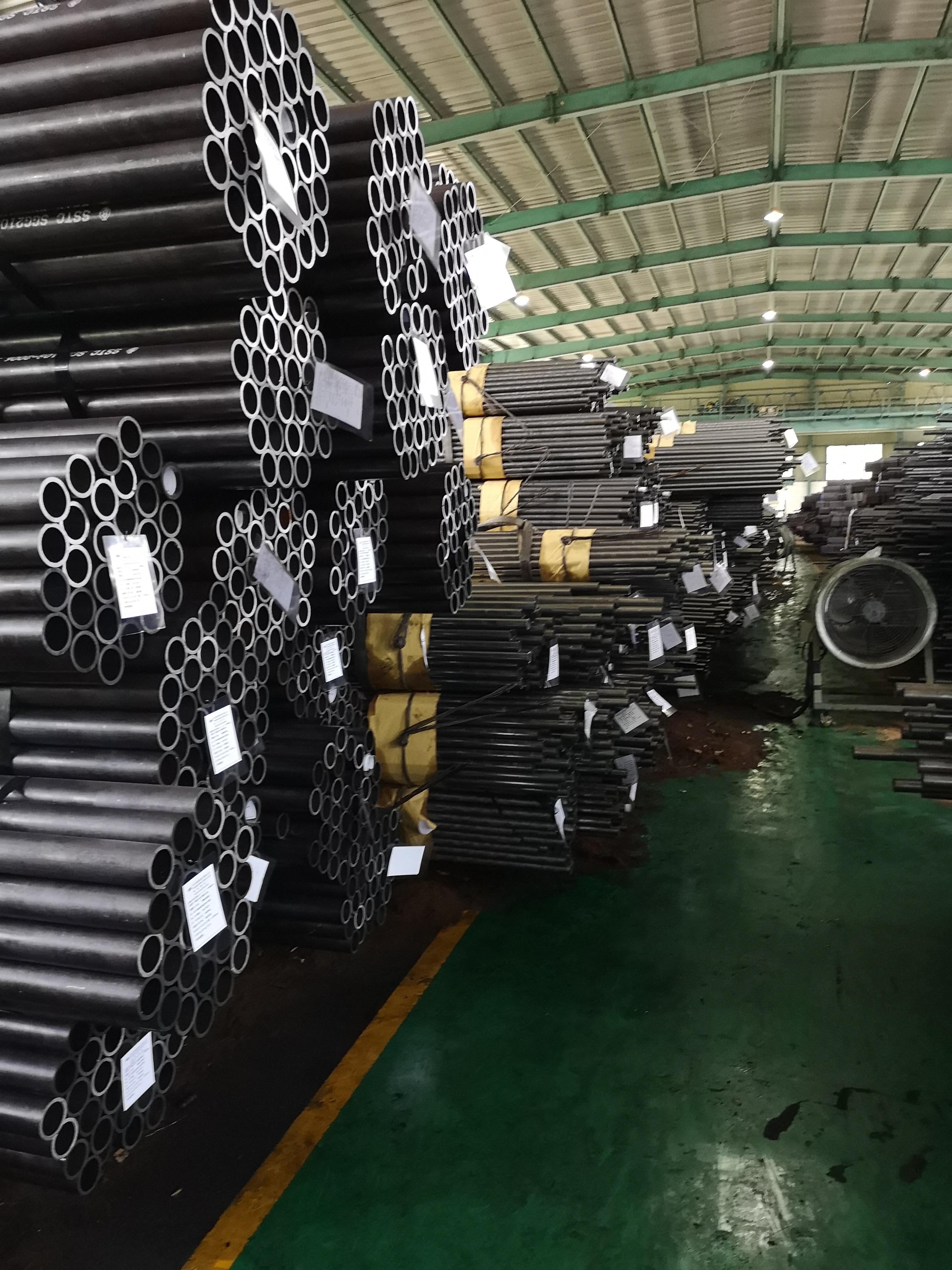

alloy steel suppliers

Alloy steel suppliers represent a critical segment of the global metals industry, providing specialized steel products that combine iron with various alloying elements to achieve enhanced mechanical properties and performance characteristics. These suppliers manufacture and distribute steel alloys containing elements such as chromium, nickel, molybdenum, manganese, silicon, and vanadium, which significantly improve the base material's strength, hardness, corrosion resistance, and temperature tolerance. The primary function of alloy steel suppliers involves sourcing raw materials, operating sophisticated manufacturing facilities, maintaining quality control systems, and establishing comprehensive distribution networks to serve diverse industrial sectors. Their technological capabilities encompass advanced metallurgical processes including electric arc furnaces, vacuum degassing systems, continuous casting technology, and precision rolling mills that ensure consistent chemical composition and mechanical properties throughout production batches. Modern alloy steel suppliers utilize computer-controlled systems for temperature management, automated quality testing equipment, and sophisticated inventory management platforms to optimize production efficiency and product reliability. These suppliers serve numerous applications across automotive manufacturing, aerospace engineering, construction infrastructure, oil and gas exploration, power generation, marine shipbuilding, and heavy machinery production. In automotive sectors, alloy steel suppliers provide materials for engine components, transmission systems, suspension parts, and safety structures that require exceptional strength-to-weight ratios and fatigue resistance. Aerospace applications demand ultra-high-performance alloys capable of withstanding extreme temperatures, stress cycles, and corrosive environments found in jet engines and structural components. Construction and infrastructure projects rely on alloy steel suppliers for reinforcement materials, structural beams, and specialized fasteners that ensure long-term durability and safety compliance. The oil and gas industry depends on these suppliers for drilling equipment, pipeline systems, and processing machinery that must resist corrosive substances and high-pressure environments.