alloy steel manufacturer

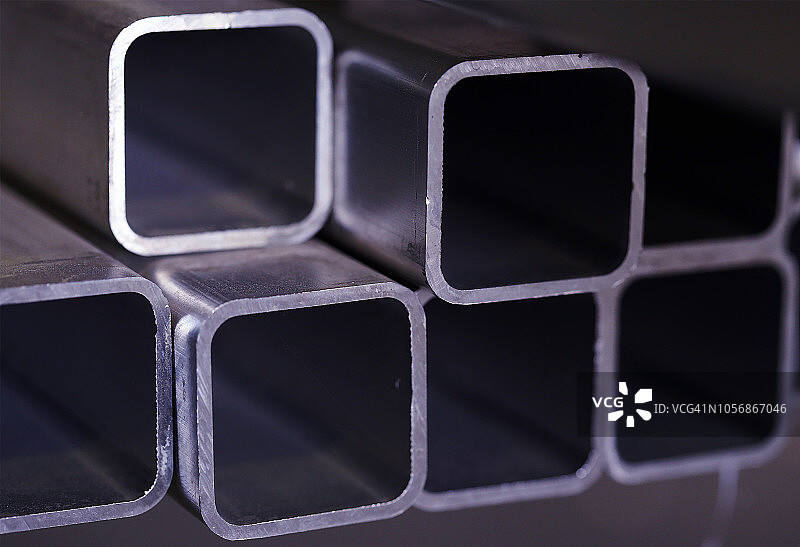

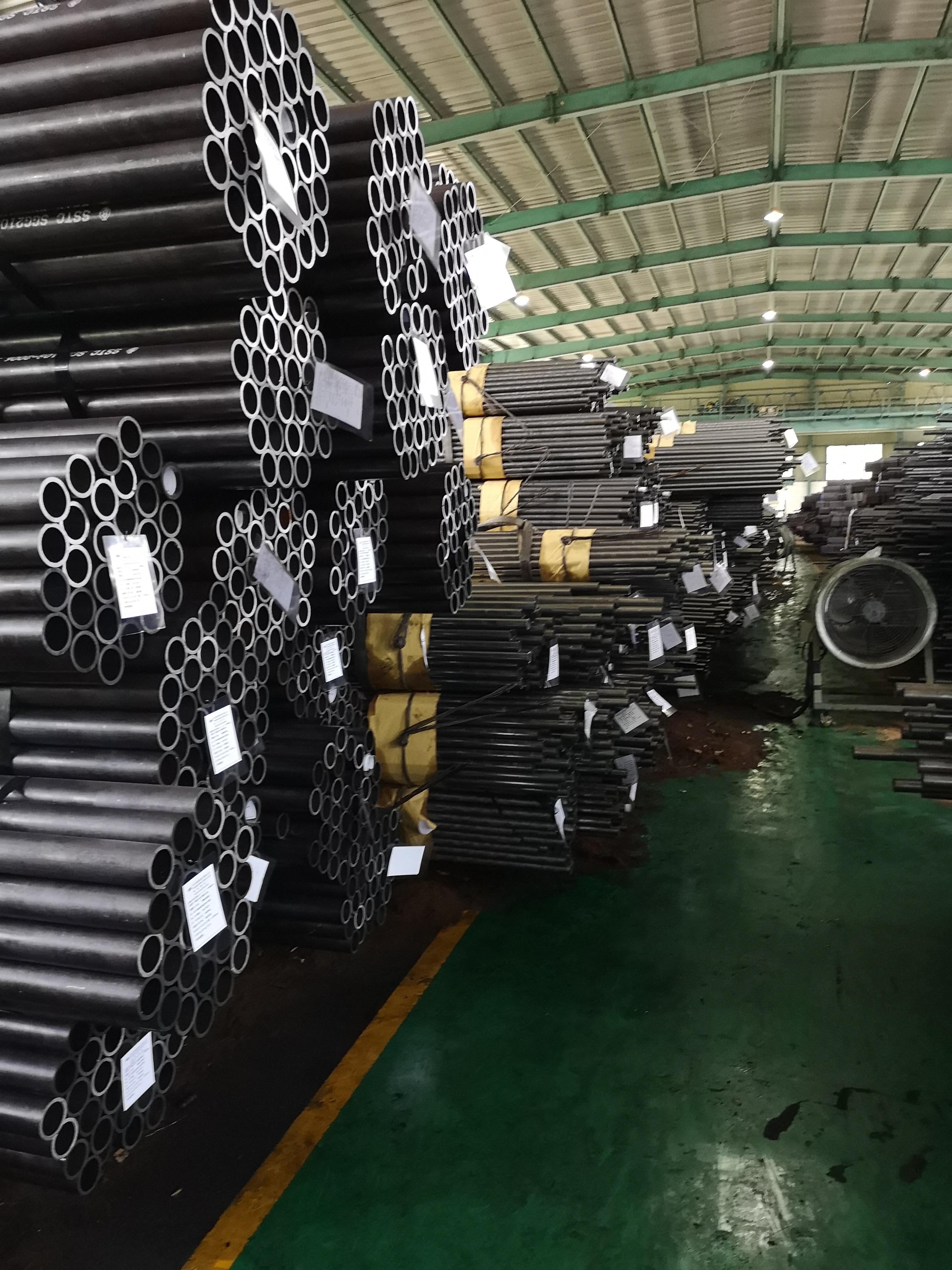

An alloy steel manufacturer serves as a specialized industrial enterprise dedicated to producing high-performance steel products by combining iron with various alloying elements such as chromium, nickel, molybdenum, vanadium, and tungsten. These companies operate sophisticated production facilities equipped with electric arc furnaces, ladle refining systems, and continuous casting machines to create custom steel compositions that meet specific industrial requirements. The primary function of an alloy steel manufacturer involves melting raw materials, precisely controlling chemical compositions, and employing advanced metallurgical processes to achieve desired mechanical properties including enhanced strength, corrosion resistance, and temperature tolerance. Modern alloy steel manufacturers utilize computer-controlled systems to monitor temperature, timing, and chemical additions throughout the production cycle, ensuring consistent quality and meeting stringent industry standards. Their technological capabilities encompass vacuum degassing, argon oxygen decarburization, and specialized heat treatment processes that optimize grain structure and eliminate impurities. These manufacturers typically maintain comprehensive quality control laboratories featuring spectrometers, tensile testing equipment, and hardness analyzers to verify product specifications. The applications for alloy steel products span numerous industries including automotive manufacturing, where high-strength components require superior fatigue resistance, aerospace applications demanding lightweight yet durable materials, construction projects requiring structural integrity, and oil and gas operations needing corrosion-resistant piping and equipment. Additionally, alloy steel manufacturers serve the power generation sector by providing materials for turbine components, the mining industry with wear-resistant equipment parts, and the marine sector through specialized stainless steel grades. Their production capabilities often include custom alloy development, working closely with engineering teams to formulate specific compositions that address unique performance challenges in demanding operational environments.