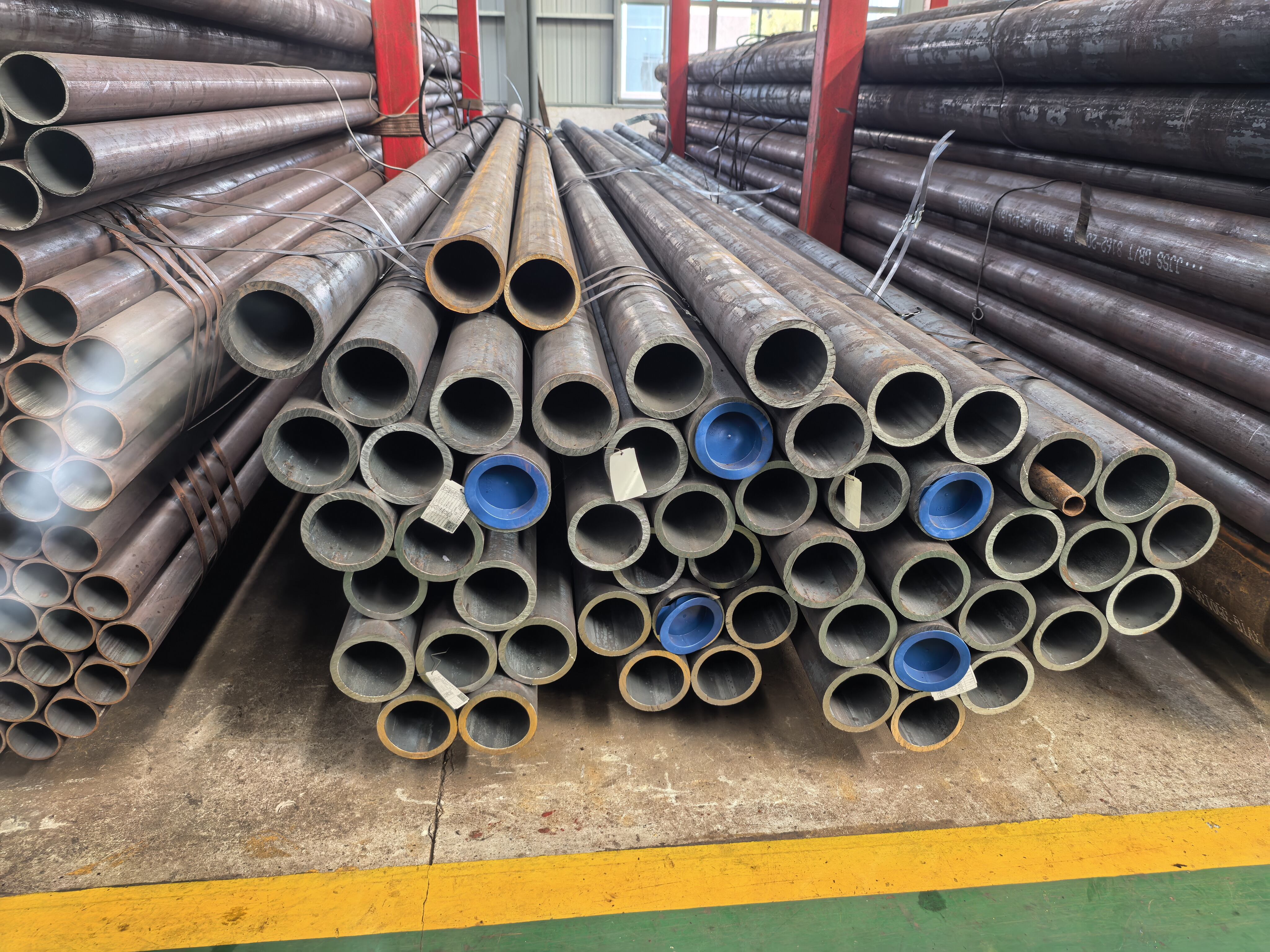

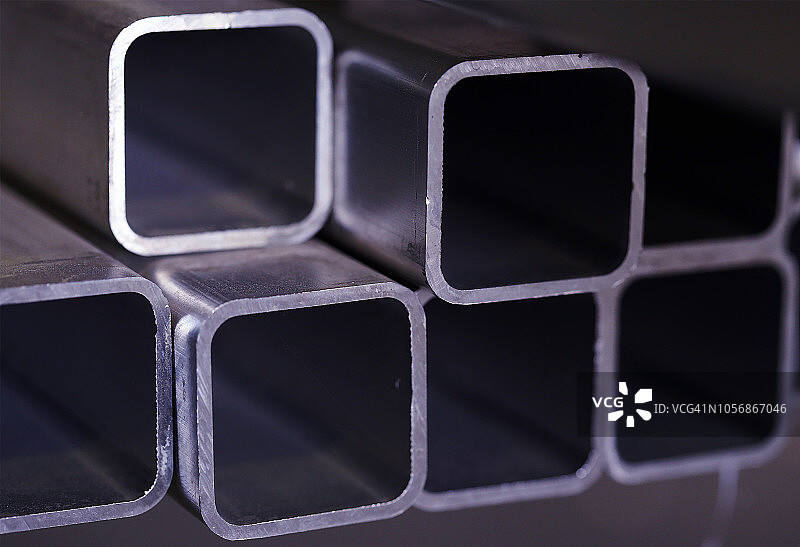

alloy steel products

Alloy steel products represent a sophisticated category of engineered materials that combine iron with carefully selected alloying elements to achieve superior performance characteristics beyond those of conventional carbon steel. These advanced metallurgical compositions typically incorporate elements such as chromium, nickel, molybdenum, vanadium, tungsten, and manganese in precise proportions to enhance specific mechanical and chemical properties. The primary functions of alloy steel products encompass providing exceptional strength-to-weight ratios, outstanding corrosion resistance, improved hardenability, and enhanced thermal stability across diverse operating conditions. Technological features of these specialized materials include superior grain refinement capabilities, controlled precipitation hardening mechanisms, and optimized phase transformation behaviors that enable precise property customization. The manufacturing process involves sophisticated melting techniques, controlled cooling protocols, and advanced heat treatment procedures that ensure consistent quality and predictable performance characteristics. Applications for alloy steel products span numerous industrial sectors, including automotive manufacturing where they form critical engine components, transmission systems, and structural elements. Aerospace industries utilize these materials for turbine blades, landing gear assemblies, and high-stress structural components that demand exceptional reliability under extreme conditions. Construction and infrastructure projects incorporate alloy steel products in bridge construction, high-rise building frameworks, and specialized architectural elements requiring long-term durability. Energy sector applications encompass power generation equipment, offshore drilling platforms, and renewable energy infrastructure components. Tool and die manufacturing industries rely heavily on alloy steel products for precision cutting tools, forming dies, and specialized machinery components that require exceptional wear resistance and dimensional stability. Marine applications include shipbuilding components, offshore platform structures, and specialized equipment designed to withstand harsh saltwater environments while maintaining structural integrity over extended service periods.