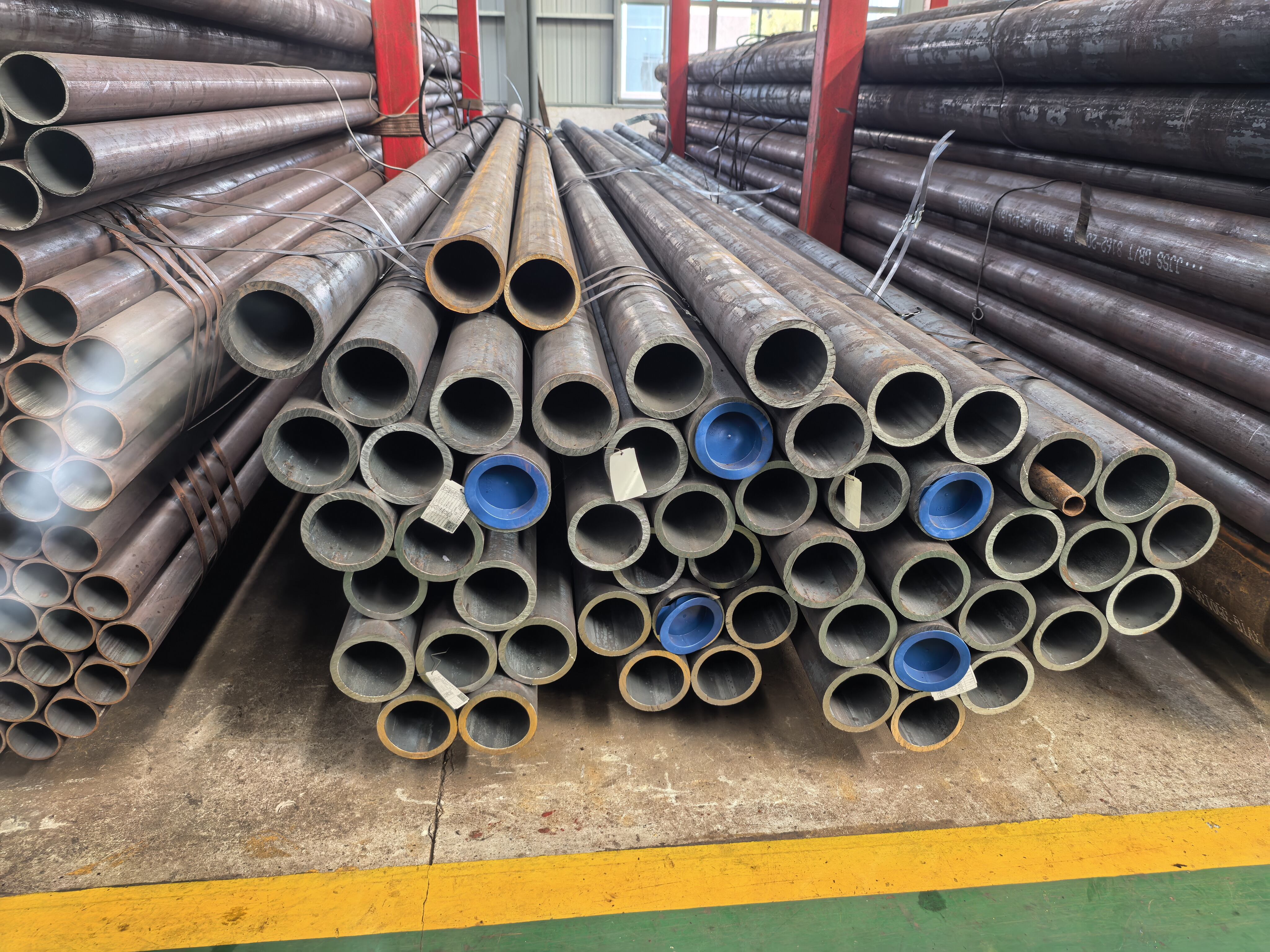

micro alloy steel

Micro alloy steel represents a revolutionary advancement in metallurgical engineering, combining the strength of traditional steel with enhanced properties achieved through precise alloying techniques. This sophisticated material incorporates small quantities of specific alloying elements, typically less than 0.1 percent by weight, including niobium, vanadium, titanium, and molybdenum. The micro alloy steel manufacturing process involves controlled cooling and thermomechanical processing, which creates a fine-grained microstructure that delivers exceptional mechanical properties. The primary functions of micro alloy steel encompass structural applications where high strength-to-weight ratios are essential, including construction frameworks, automotive components, pipeline systems, and heavy machinery manufacturing. Technological features of this advanced material include superior yield strength, improved weldability, enhanced toughness at low temperatures, and excellent fatigue resistance. The precipitation hardening mechanism inherent in micro alloy steel allows for strength increases without compromising ductility, making it ideal for demanding applications. Manufacturing processes utilize sophisticated temperature control during rolling and cooling phases, ensuring optimal grain refinement and precipitation distribution. Applications span across multiple industries, from oil and gas exploration equipment to bridge construction and shipbuilding. The automotive sector particularly benefits from micro alloy steel in chassis components, suspension systems, and safety structures where weight reduction without strength compromise is crucial. Construction applications include high-rise buildings, stadiums, and infrastructure projects requiring materials that can withstand seismic activity and extreme weather conditions. The versatility of micro alloy steel extends to pressure vessels, mining equipment, and agricultural machinery, where durability and reliability are paramount concerns for operational efficiency.