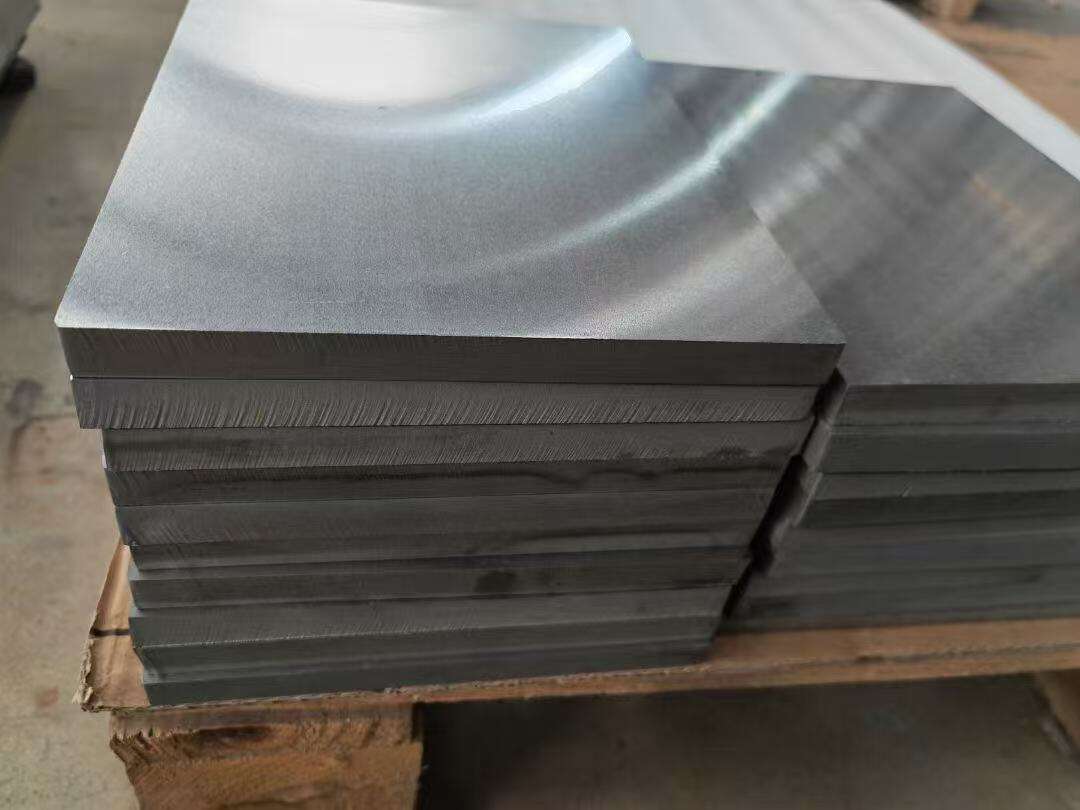

abrasion resistant steel plate

Abrasion resistant steel plate represents a specialized category of high-performance steel engineered to withstand extreme wear conditions in demanding industrial environments. These plates are manufactured using advanced metallurgical processes that create a unique microstructure capable of resisting surface degradation caused by friction, impact, and continuous contact with abrasive materials. The primary function of abrasion resistant steel plate is to provide extended service life in applications where conventional steel would quickly deteriorate, making it an essential component in heavy industry operations. The technological features of abrasion resistant steel plate include controlled chemical composition with optimized carbon content, specialized heat treatment processes, and precise hardness levels typically ranging from 400 to 500 HBW. Manufacturing involves sophisticated quenching and tempering techniques that create a hard surface layer while maintaining a tough core structure. This dual-layer approach ensures the plate can absorb impact energy without cracking while maintaining superior surface hardness. The steel plate exhibits excellent weldability characteristics, allowing for easy fabrication and installation in complex industrial equipment. Applications for abrasion resistant steel plate span numerous industries including mining, construction, cement production, steel manufacturing, and material handling systems. In mining operations, these plates protect chute liners, conveyor systems, and crushing equipment from the constant wear caused by ore and rock materials. Construction equipment manufacturers utilize abrasion resistant steel plate in excavator buckets, bulldozer blades, and dump truck bodies where exposure to sand, gravel, and debris is constant. The cement industry relies on this specialized steel for kiln components, cyclone separators, and material transport systems where limestone and clinker cause severe abrasive wear. Power generation facilities use abrasion resistant steel plate in coal handling systems, ash removal equipment, and boiler components where coal particles create challenging wear conditions.