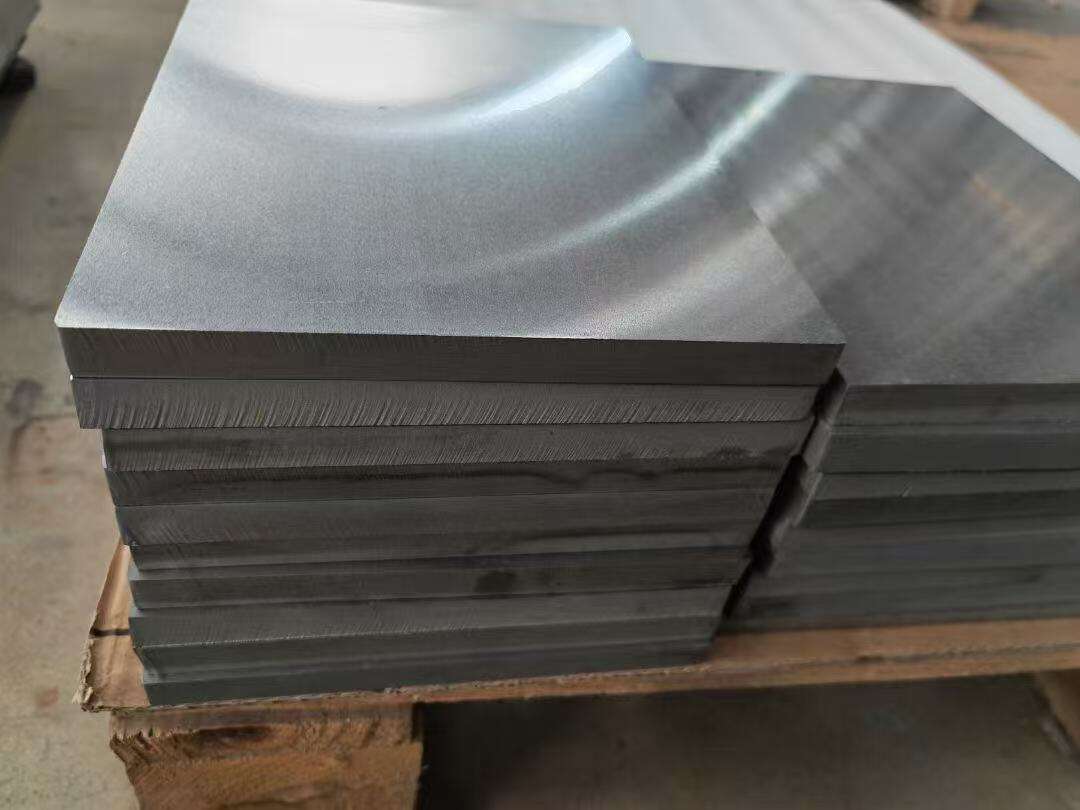

steel plate manufacturers

Steel plate manufacturers represent the backbone of modern industrial production, serving as critical suppliers of high-quality steel plates across diverse sectors worldwide. These specialized companies focus on producing flat-rolled steel products through sophisticated manufacturing processes that transform raw steel into precision-engineered plates suitable for countless applications. The primary function of steel plate manufacturers involves melting, rolling, and finishing steel to create products with specific dimensions, chemical compositions, and mechanical properties tailored to customer requirements. Modern steel plate manufacturers utilize advanced technology including electric arc furnaces, continuous casting systems, and state-of-the-art rolling mills to achieve consistent quality and dimensional accuracy. Their technological capabilities encompass precise temperature control, automated thickness regulation, and computerized quality monitoring systems that ensure each plate meets stringent industry standards. These manufacturers typically offer extensive product ranges including carbon steel plates, alloy steel plates, stainless steel plates, and specialized high-strength variants designed for demanding environments. The applications for products from steel plate manufacturers span construction industries where structural steel plates form building frameworks, shipbuilding sectors requiring marine-grade materials, energy production facilities utilizing pressure vessel plates, and automotive industries demanding lightweight yet durable components. Mining equipment, agricultural machinery, and infrastructure projects also rely heavily on products from reliable steel plate manufacturers. Quality control remains paramount, with manufacturers implementing comprehensive testing protocols including chemical analysis, mechanical property verification, and non-destructive testing methods. Leading steel plate manufacturers maintain certifications from international standards organizations, ensuring their products comply with global quality benchmarks and regulatory requirements across different markets and applications.