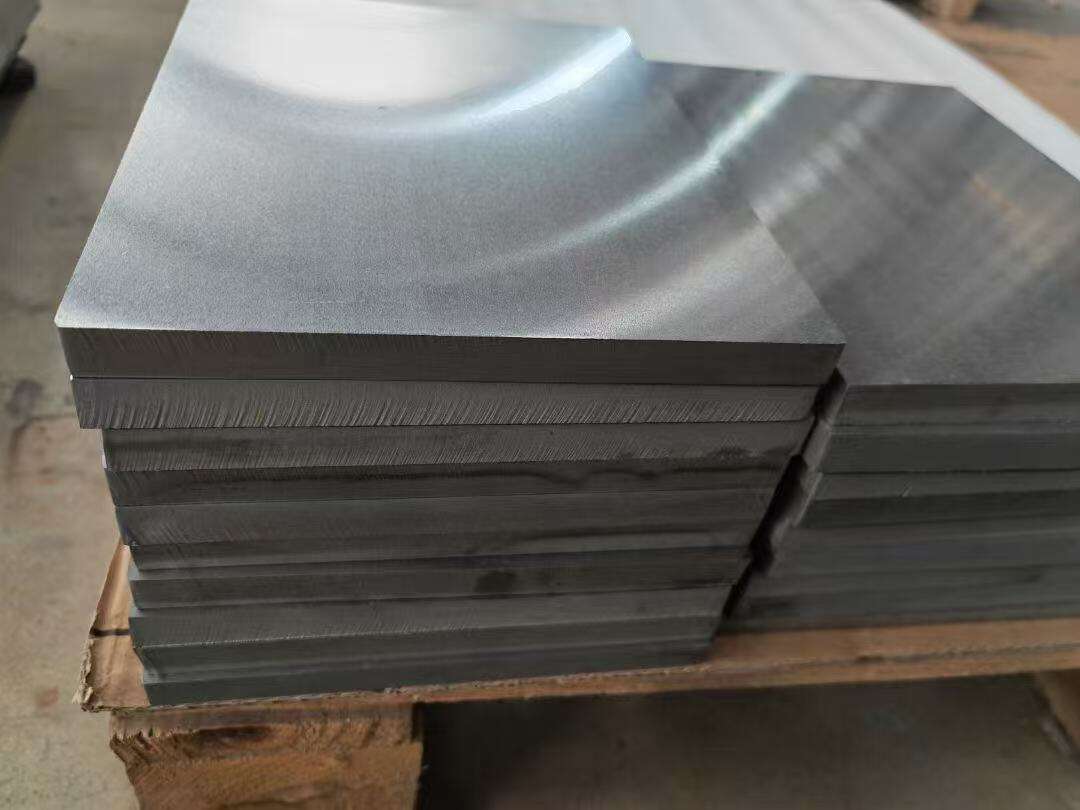

spring steel plate

A spring steel plate represents a specialized metal component engineered to provide exceptional elasticity, durability, and mechanical performance across diverse industrial applications. This high-carbon steel product undergoes precise heat treatment processes to achieve optimal spring characteristics, making it an essential component in manufacturing, automotive, construction, and machinery sectors. The spring steel plate exhibits superior tensile strength, typically ranging from 1200 to 1800 MPa, while maintaining excellent fatigue resistance properties that ensure long-term reliability under repeated stress cycles. Manufacturing processes involve controlled carbon content adjustment, usually between 0.6% to 1.0%, combined with strategic alloying elements such as silicon, manganese, and chromium to enhance performance characteristics. The spring steel plate functions primarily as a load-bearing element that absorbs, stores, and releases mechanical energy efficiently. Its technological features include remarkable elastic deformation capabilities, allowing the material to return to its original shape after stress removal without permanent deformation. Temperature stability remains consistent across wide operating ranges, typically from -40°C to 200°C, making spring steel plate suitable for demanding environmental conditions. Surface treatments such as shot peening, phosphating, or coating applications further enhance corrosion resistance and operational lifespan. Key applications encompass automotive suspension systems, industrial machinery components, agricultural equipment, railway systems, and precision instruments. The spring steel plate serves critical functions in shock absorption, vibration dampening, energy storage, and mechanical force transmission. Manufacturing industries rely on spring steel plate for creating leaf springs, coil springs, flat springs, and custom-shaped elastic components. Quality standards typically conform to ASTM, DIN, JIS, or ISO specifications, ensuring consistent performance and reliability. The versatility of spring steel plate extends to architectural applications, where it provides structural flexibility and seismic resistance in building systems.