types of steel plates

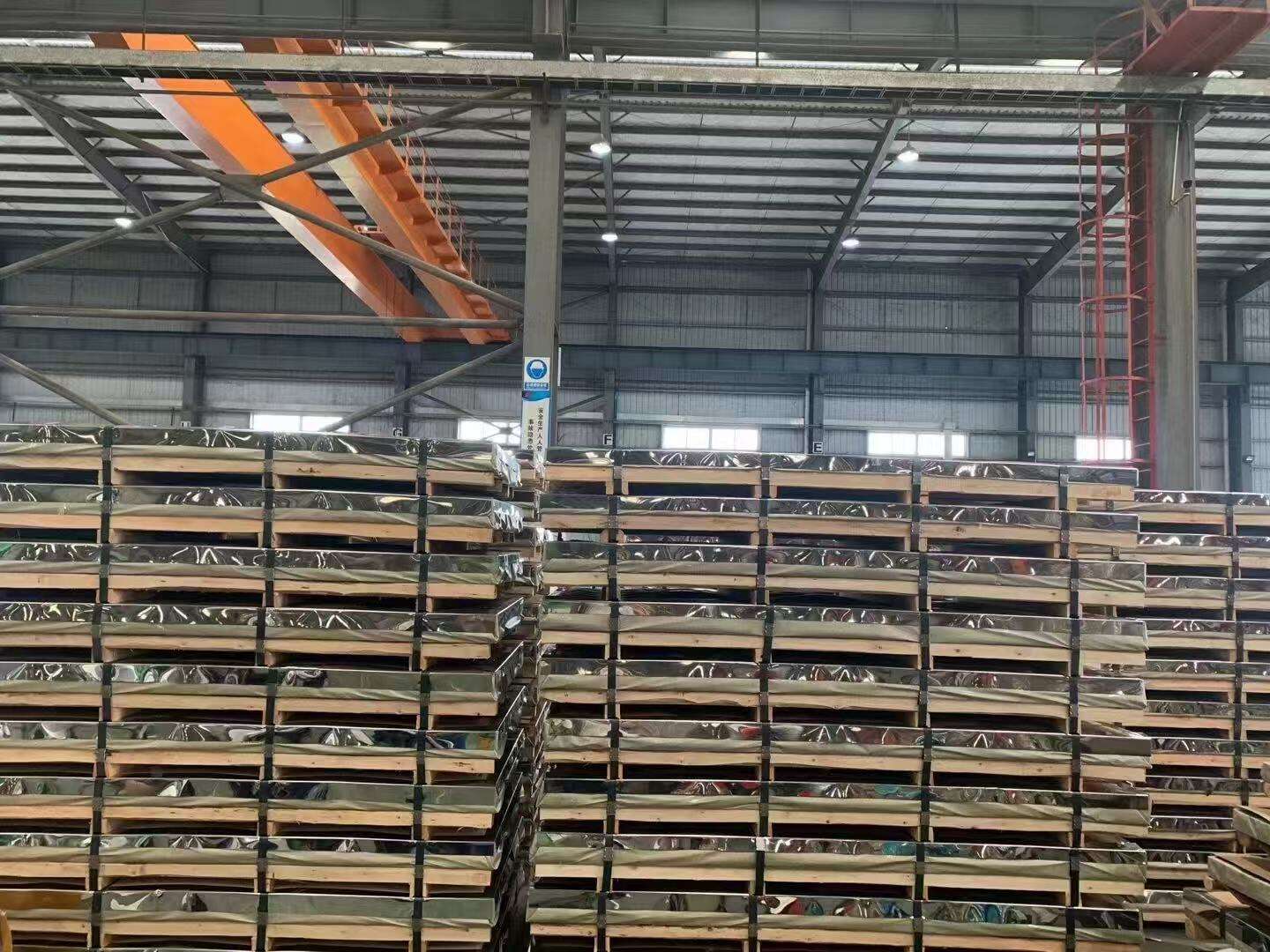

Steel plates represent one of the most versatile and essential materials in modern construction and manufacturing industries. These flat-rolled steel products come in various types of steel plates, each engineered to meet specific performance requirements and applications. Carbon steel plates form the foundation of this category, offering excellent strength-to-weight ratios and cost-effectiveness for general construction purposes. Alloy steel plates incorporate additional elements like chromium, nickel, or molybdenum to enhance specific properties such as corrosion resistance, hardness, or temperature tolerance. Stainless steel plates provide superior corrosion resistance through chromium content, making them ideal for food processing, chemical industries, and marine applications. High-strength low-alloy plates deliver enhanced mechanical properties while maintaining weldability and formability. The technological features of these types of steel plates include precise thickness control, consistent chemical composition, and advanced surface finishes that ensure optimal performance in demanding environments. Manufacturing processes involve controlled rolling, heat treatment, and quality testing to achieve specific mechanical properties like tensile strength, yield strength, and impact resistance. Different types of steel plates undergo specialized treatments such as quenching, tempering, or normalization to optimize their microstructure and performance characteristics. Surface treatments including shot blasting, pickling, or coating application further enhance their functionality and longevity. Applications span across construction, shipbuilding, pressure vessels, automotive manufacturing, and infrastructure development. Each type serves specific purposes: structural plates for building frameworks, wear-resistant plates for mining equipment, and high-temperature plates for power generation facilities. The selection of appropriate types of steel plates depends on factors including load requirements, environmental conditions, temperature exposure, and chemical compatibility, ensuring optimal performance and safety in their intended applications.