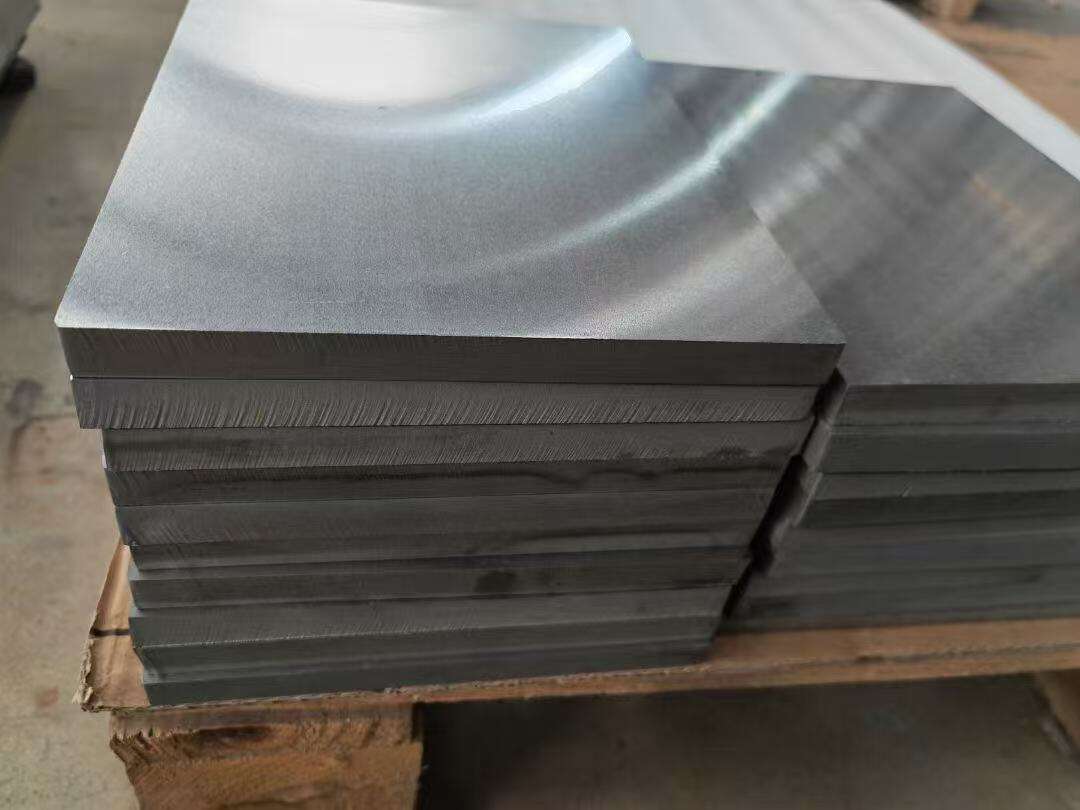

custom steel plate

Custom steel plate represents a revolutionary approach to metal fabrication, offering precisely engineered solutions tailored to meet specific industrial requirements. This specialized manufacturing process transforms raw steel materials into bespoke products that align perfectly with unique project specifications and operational demands. The custom steel plate manufacturing process involves advanced metallurgical techniques, computer-aided design systems, and precision cutting technologies that ensure each product delivers exceptional performance characteristics. These steel plates undergo rigorous quality control measures, including chemical composition analysis, mechanical property testing, and dimensional accuracy verification to guarantee superior results. The technological features of custom steel plate include variable thickness options ranging from ultra-thin sheets to heavy-duty plates, customizable alloy compositions that enhance specific properties like corrosion resistance or heat tolerance, and precise dimensional cutting that eliminates waste and reduces installation time. Advanced heat treatment processes further optimize the material properties, creating steel plates with enhanced strength-to-weight ratios and improved durability characteristics. Applications for custom steel plate span numerous industries, including construction, automotive manufacturing, shipbuilding, energy production, and aerospace engineering. In construction projects, these plates serve as structural components, foundation elements, and architectural features that require specific load-bearing capabilities. The automotive industry utilizes custom steel plate for chassis components, body panels, and safety structures that must meet stringent crash test requirements. Marine applications benefit from corrosion-resistant custom steel plate formulations that withstand harsh saltwater environments while maintaining structural integrity. Energy sector applications include pressure vessels, pipeline components, and renewable energy infrastructure that demand exceptional reliability and longevity. The precision manufacturing process ensures consistent quality across production runs while maintaining cost-effectiveness for both small-batch specialty orders and large-scale industrial projects.