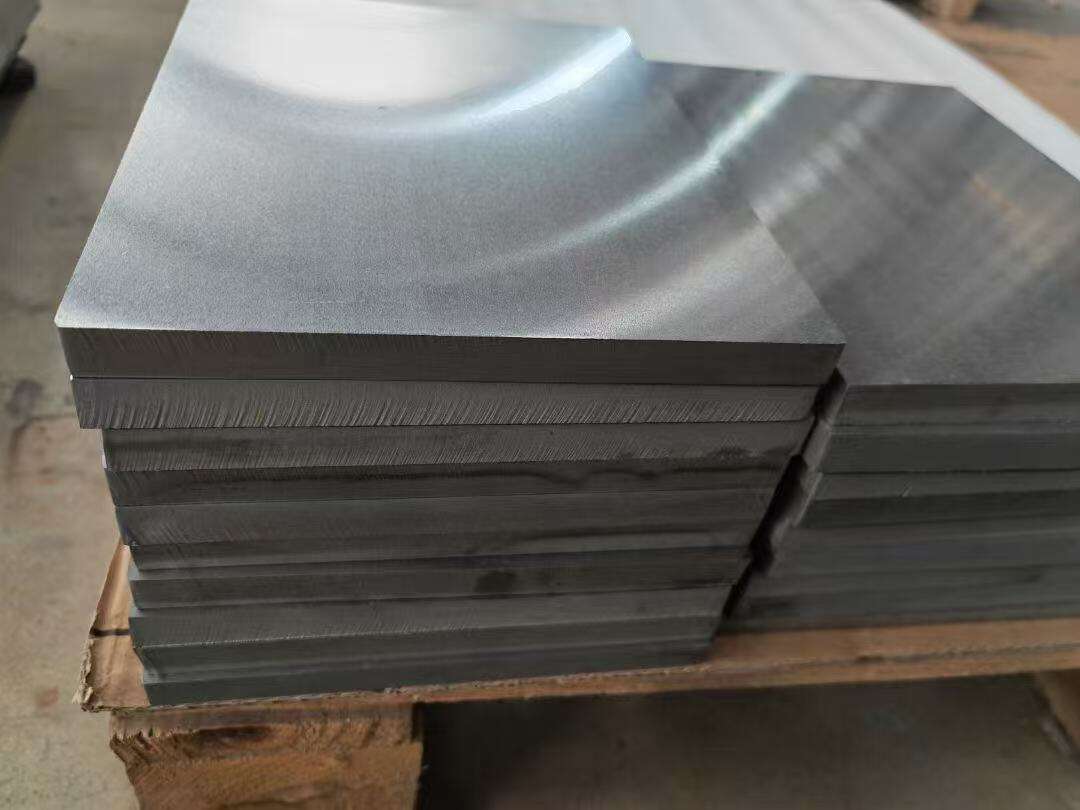

stainless steel plate suppliers

Stainless steel plate suppliers serve as crucial intermediaries in the global metals industry, connecting manufacturers with businesses requiring high-quality corrosion-resistant materials. These specialized companies source, stock, and distribute various grades of stainless steel plates to meet diverse industrial demands. Modern stainless steel plate suppliers utilize advanced inventory management systems, quality control protocols, and logistics networks to ensure consistent product availability and timely delivery. Their main functions encompass procurement from certified mills, quality verification, warehousing, processing services, and customer support. Stainless steel plate suppliers typically maintain extensive inventories of different grades including 304, 316, 321, and duplex varieties in various thicknesses and finishes. They employ sophisticated testing equipment to verify material composition, mechanical properties, and surface quality before distribution. Many suppliers offer value-added services such as cutting, drilling, forming, and surface treatments to meet specific customer requirements. Their technological infrastructure includes computerized inventory systems, material handling equipment, precision cutting machinery, and quality assurance laboratories. Advanced suppliers implement digital platforms for order processing, real-time inventory tracking, and customer communication. The applications served by stainless steel plate suppliers span numerous industries including food processing, pharmaceutical manufacturing, chemical processing, marine construction, architectural projects, and energy production. These suppliers play essential roles in construction projects requiring corrosion resistance, food industry applications demanding hygiene standards, and chemical plants needing material compatibility. Their expertise extends to material selection guidance, technical support, and compliance with industry standards such as ASTM, AISI, and international specifications. Professional stainless steel plate suppliers maintain certifications, traceability documentation, and quality management systems to ensure product integrity throughout the supply chain.