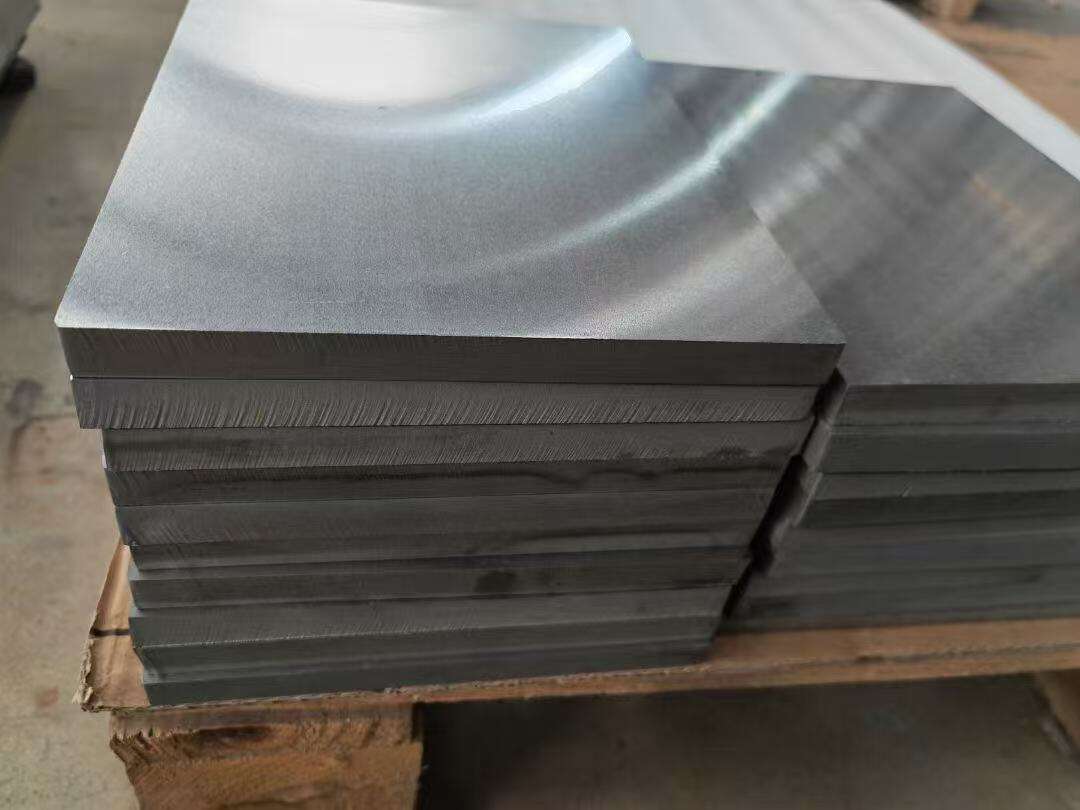

alloy steel plate

Alloy steel plate represents a sophisticated metallurgical solution that combines the fundamental strength of carbon steel with carefully selected alloying elements to create superior performance materials. This engineered steel product incorporates elements such as chromium, nickel, molybdenum, vanadium, and tungsten in precise proportions to enhance specific mechanical properties. The manufacturing process involves controlled heating, rolling, and cooling procedures that optimize the microstructure and ensure consistent quality throughout the material. These plates serve as critical components in demanding industrial applications where standard carbon steel cannot meet performance requirements. The primary functions of alloy steel plate include structural support in high-stress environments, pressure containment in vessels and pipelines, wear resistance in mining and construction equipment, and corrosion protection in chemical processing facilities. Technological features distinguish alloy steel plate through its enhanced hardenability, which allows for deeper penetration of heat treatment effects, resulting in uniform properties across thick sections. The material exhibits superior tensile strength, often exceeding 80,000 psi, while maintaining excellent ductility and impact resistance. Temperature stability remains consistent across wide operating ranges, making these plates suitable for both cryogenic and high-temperature applications. Fabrication characteristics include excellent weldability with proper preheating and post-weld heat treatment procedures. Applications span diverse industries including aerospace, where weight-to-strength ratios are critical, automotive manufacturing for chassis and engine components, oil and gas exploration for drilling equipment and pipeline systems, power generation for boiler construction and turbine housings, and marine engineering for hull plating and propulsion systems. The versatility of alloy steel plate makes it indispensable in modern industrial applications requiring exceptional performance under challenging conditions.