buy steel plate

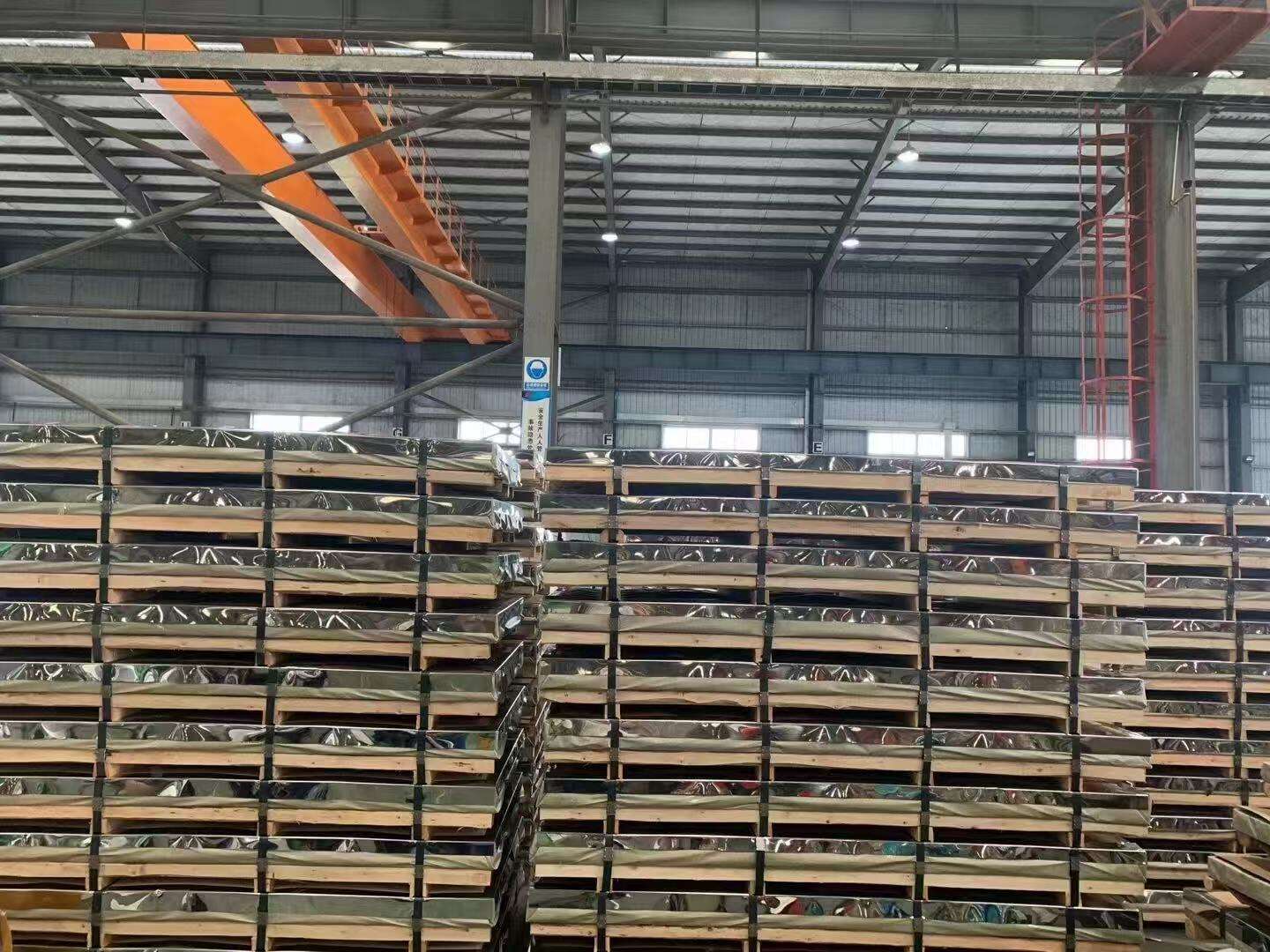

When you buy steel plate, you invest in one of the most versatile and essential materials for construction, manufacturing, and industrial applications. Steel plates are flat-rolled steel products manufactured through hot rolling or cold rolling processes, creating uniform thickness sheets that serve as fundamental building blocks across numerous industries. These robust metal sheets exhibit exceptional strength-to-weight ratios, making them indispensable for structural frameworks, heavy machinery, shipbuilding, and architectural projects. The decision to buy steel plate requires understanding various grades, thicknesses, and surface finishes available in today's market. Carbon steel plates offer excellent weldability and formability, while alloy steel plates provide enhanced corrosion resistance and specialized properties for demanding environments. Stainless steel plates deliver superior corrosion protection and aesthetic appeal for food processing, chemical industries, and decorative applications. The manufacturing process involves melting raw materials in electric arc furnaces, continuous casting into slabs, and subsequent rolling to achieve desired dimensions. Quality control measures ensure consistent mechanical properties, dimensional accuracy, and surface quality that meet international standards like ASTM, EN, and JIS specifications. Modern steel plate production incorporates advanced technologies including computer-controlled rolling mills, automated thickness monitoring, and precision cutting systems. Surface treatments such as pickling, oiling, and coating preparation enhance durability and processing characteristics. When you buy steel plate, thickness options typically range from 3mm to 300mm, with widths up to 4000mm and lengths extending to 18000mm. Edge conditions include mill edge, sheared edge, and flame-cut edge, each serving specific fabrication requirements. Heat treatment processes like normalizing, quenching, and tempering modify mechanical properties to meet application-specific demands. Understanding these characteristics ensures optimal material selection when you buy steel plate for your project requirements.