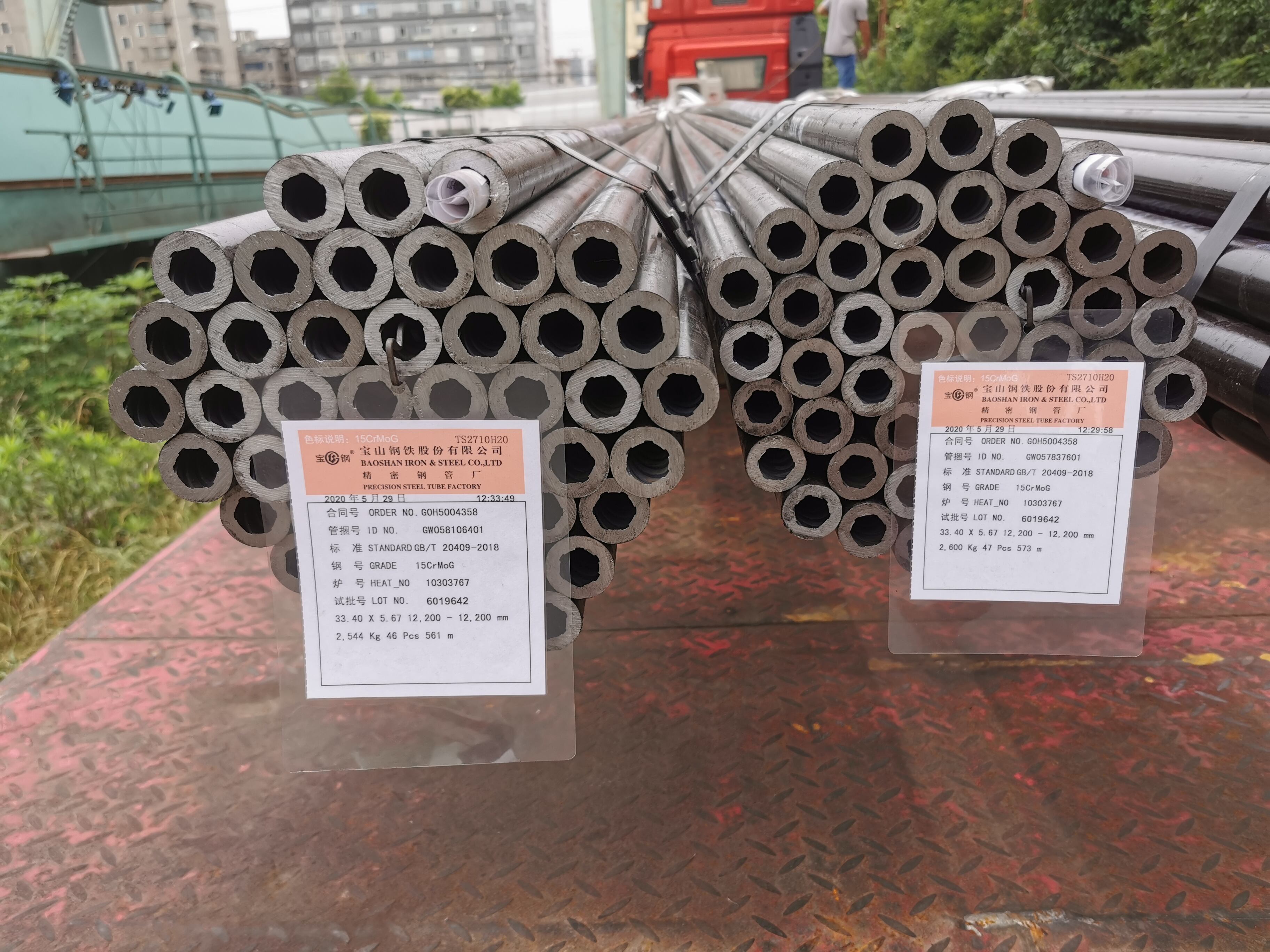

boiler tube

Boiler tubes represent critical components within steam generation systems, serving as the primary conduits for heat transfer and fluid circulation in industrial and commercial applications. These specialized tubes form the backbone of boiler operations, facilitating the conversion of water into steam through controlled heat exchange processes. A boiler tube typically consists of high-grade steel or alloy materials designed to withstand extreme temperatures and pressures while maintaining structural integrity over extended operational periods. The primary function of these tubes involves creating pathways for hot gases or flames to pass through while water circulates around the exterior surfaces, enabling efficient thermal energy transfer. This fundamental heat exchange mechanism allows boilers to generate steam for power production, heating systems, and various industrial processes. Modern boiler tube designs incorporate advanced metallurgical technologies that enhance performance characteristics such as thermal conductivity, corrosion resistance, and mechanical strength. These tubes operate within complex networks that include water walls, superheaters, economizers, and reheaters, each serving specific roles in optimizing steam generation efficiency. The technological features of contemporary boiler tubes include precision manufacturing processes that ensure consistent wall thickness, smooth internal surfaces, and exact dimensional tolerances. These specifications are crucial for maintaining proper fluid dynamics and preventing hot spots that could lead to tube failure. Applications for boiler tubes span diverse industries including power generation facilities, petrochemical plants, food processing operations, pharmaceutical manufacturing, and district heating systems. The versatility of these components makes them indispensable for any facility requiring reliable steam production or hot water circulation for operational processes.