superheater tube

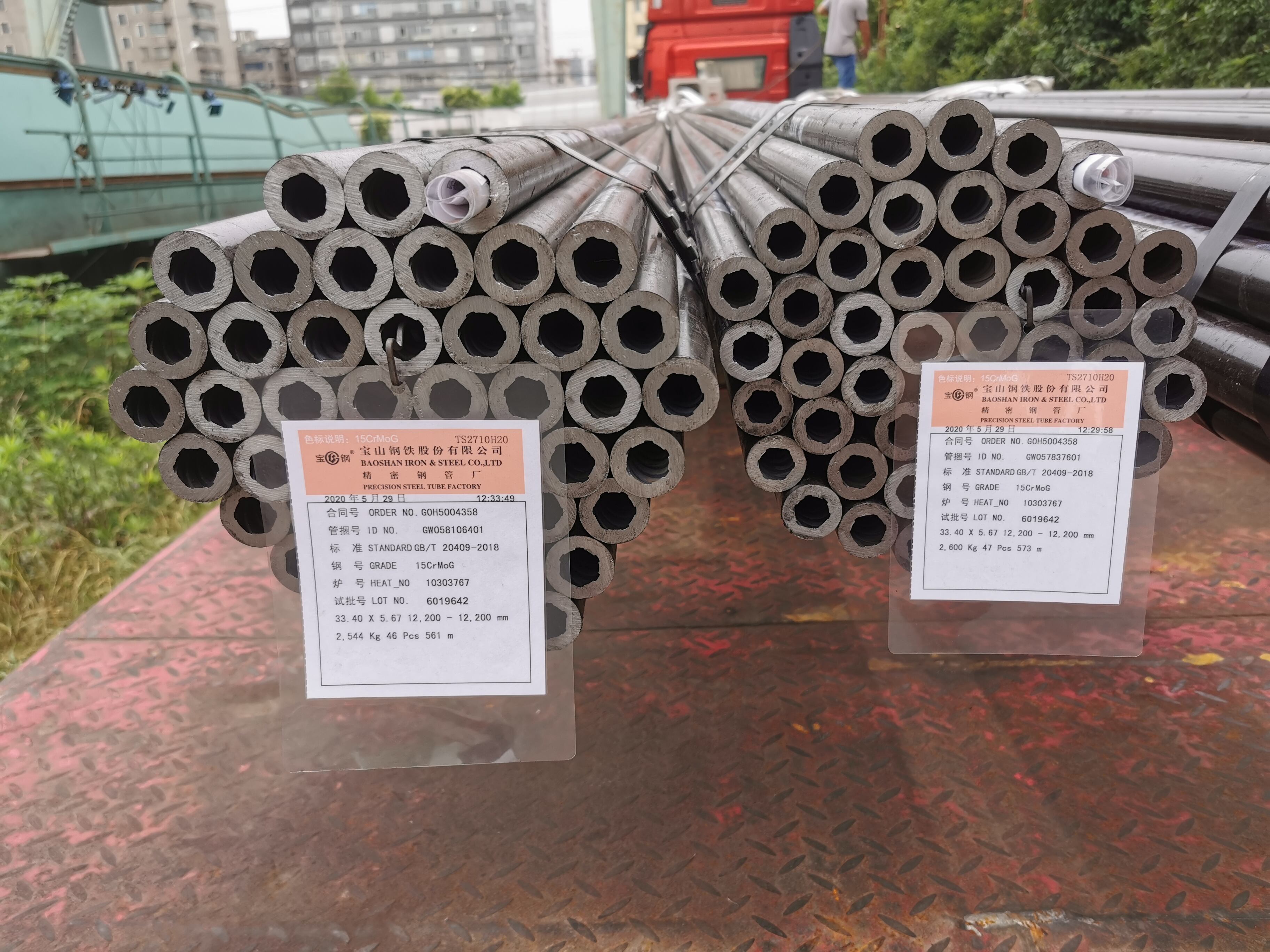

A superheater tube is a critical component in steam generation systems that transforms saturated steam into superheated steam by raising its temperature beyond the saturation point. This essential element operates within the superheater section of boilers, where it facilitates heat transfer from combustion gases to steam. The superheater tube system consists of multiple parallel tubes arranged in banks or coils, strategically positioned to maximize heat absorption efficiency. These tubes are manufactured from high-grade materials capable of withstanding extreme temperatures and pressures encountered in industrial applications. The primary function involves converting wet steam into dry superheated steam, which significantly improves thermal efficiency and prevents condensation damage in downstream equipment. Superheater tubes are engineered with precise dimensional specifications to ensure optimal flow characteristics and heat transfer rates. The design incorporates advanced metallurgical properties that resist corrosion, oxidation, and thermal stress cracking. Modern superheater tube configurations feature enhanced surface areas through internal rifling or external fins, promoting superior heat exchange performance. The operational mechanism relies on radiant and convective heat transfer principles, where hot gases from the combustion chamber transfer energy to the steam flowing through the tubes. Temperature control systems monitor and regulate the superheater tube performance to maintain desired steam conditions. Installation typically occurs in the hottest section of the boiler, where gas temperatures range from 800 to 1200 degrees Celsius. The superheater tube arrangement can be horizontal, vertical, or serpentine, depending on boiler design requirements and space constraints. Quality superheater tubes undergo rigorous testing procedures including hydrostatic pressure tests, non-destructive examinations, and material certification processes. These components play a vital role in power generation, petrochemical processing, and various industrial applications requiring high-temperature steam.