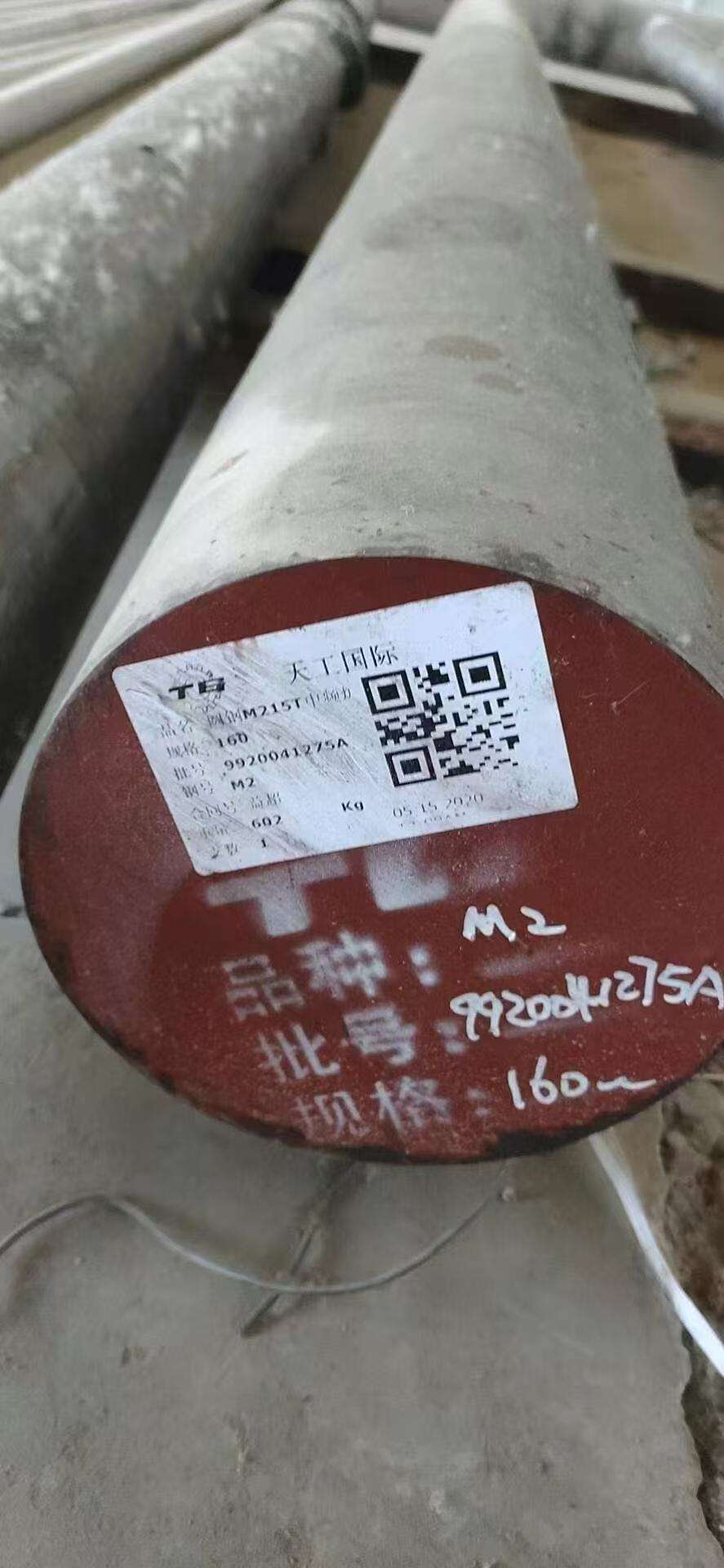

die steel

Die steel represents a specialized category of tool steel engineered specifically for manufacturing dies, molds, and forming tools used in various industrial processes. This high-performance material combines exceptional hardness, wear resistance, and dimensional stability to withstand the extreme pressures and repetitive stresses encountered in metalworking operations. Die steel serves as the backbone of modern manufacturing, enabling the production of precision components across automotive, aerospace, electronics, and consumer goods industries. The primary functions of die steel include forming, cutting, punching, and shaping operations where materials undergo plastic deformation under high pressure. These steels maintain their shape and cutting edge integrity even when subjected to temperatures exceeding 500 degrees Celsius and pressures reaching several tons per square inch. The technological features of die steel encompass carefully balanced chemical compositions that typically include chromium, molybdenum, vanadium, and tungsten as alloying elements. These additions enhance hardenability, improve hot strength, and provide resistance to thermal fatigue and cracking. Advanced heat treatment processes transform die steel into a material with hardness levels ranging from 58 to 65 HRC while maintaining sufficient toughness to prevent brittle failure. The microstructure consists of fine carbides dispersed throughout a martensitic matrix, creating an optimal combination of hardness and impact resistance. Applications span across multiple sectors including automotive stamping dies for body panels, progressive dies for electronic component manufacturing, forging dies for engine parts, and plastic injection mold tooling. The versatility of die steel extends to cold forming operations such as blanking, piercing, and bending, as well as hot forming processes including forging, extrusion, and die casting. Modern die steel grades incorporate advanced metallurgical techniques such as powder metallurgy and vacuum processing to achieve superior cleanliness and homogeneity, resulting in extended tool life and improved surface finish quality.