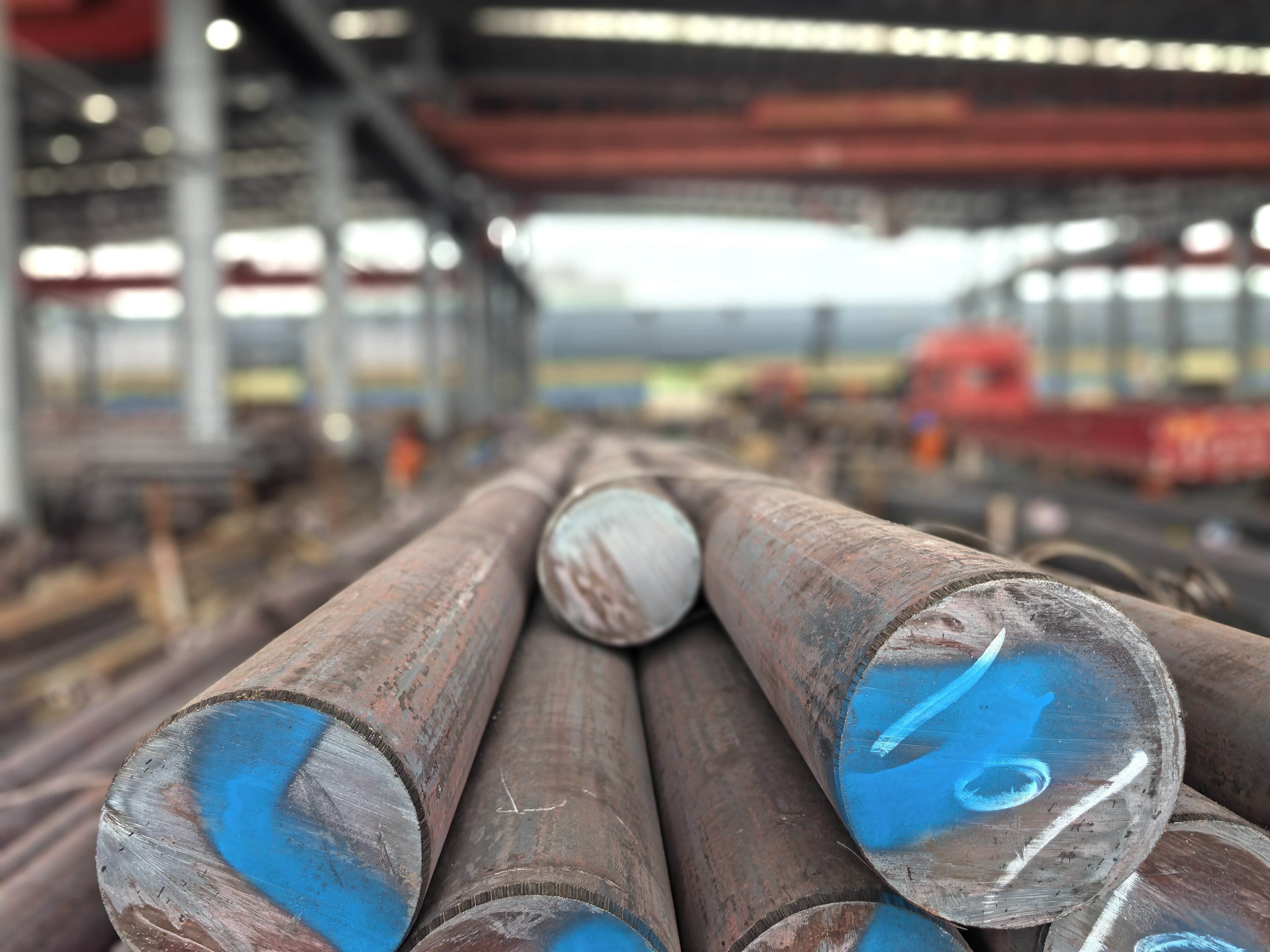

high speed steel types

High speed steel types represent a revolutionary advancement in metallurgy, engineered specifically for cutting tools and manufacturing applications that demand exceptional performance under extreme conditions. These specialized alloy steels contain significant amounts of tungsten, molybdenum, vanadium, and chromium, creating materials that maintain their hardness and cutting efficiency even at elevated temperatures generated during high-speed machining operations. The primary function of high speed steel types centers on their ability to withstand thermal stress while preserving sharp cutting edges, making them indispensable for industrial manufacturing processes. Technological features of these steel varieties include superior wear resistance, enhanced toughness, and remarkable heat resistance that allows continuous operation at temperatures exceeding 600 degrees Celsius without significant performance degradation. The crystalline structure of high speed steel types undergoes carefully controlled heat treatment processes that optimize carbide distribution throughout the matrix, resulting in tools that deliver consistent performance across extended operational periods. Applications for high speed steel types span numerous industries, including automotive manufacturing, aerospace engineering, construction, and precision machining operations. These materials excel in producing drill bits, end mills, saw blades, and cutting tools that require sustained performance under demanding conditions. Manufacturing facilities rely on high speed steel types for creating components that must maintain dimensional accuracy while processing various materials ranging from soft metals to hardened alloys. The versatility of these steel compositions allows manufacturers to select specific high speed steel types based on particular application requirements, whether prioritizing cutting speed, tool longevity, or surface finish quality. Advanced metallurgical techniques continue to refine high speed steel types, incorporating new alloying elements and processing methods that push performance boundaries further, ensuring these materials remain at the forefront of modern manufacturing technology.