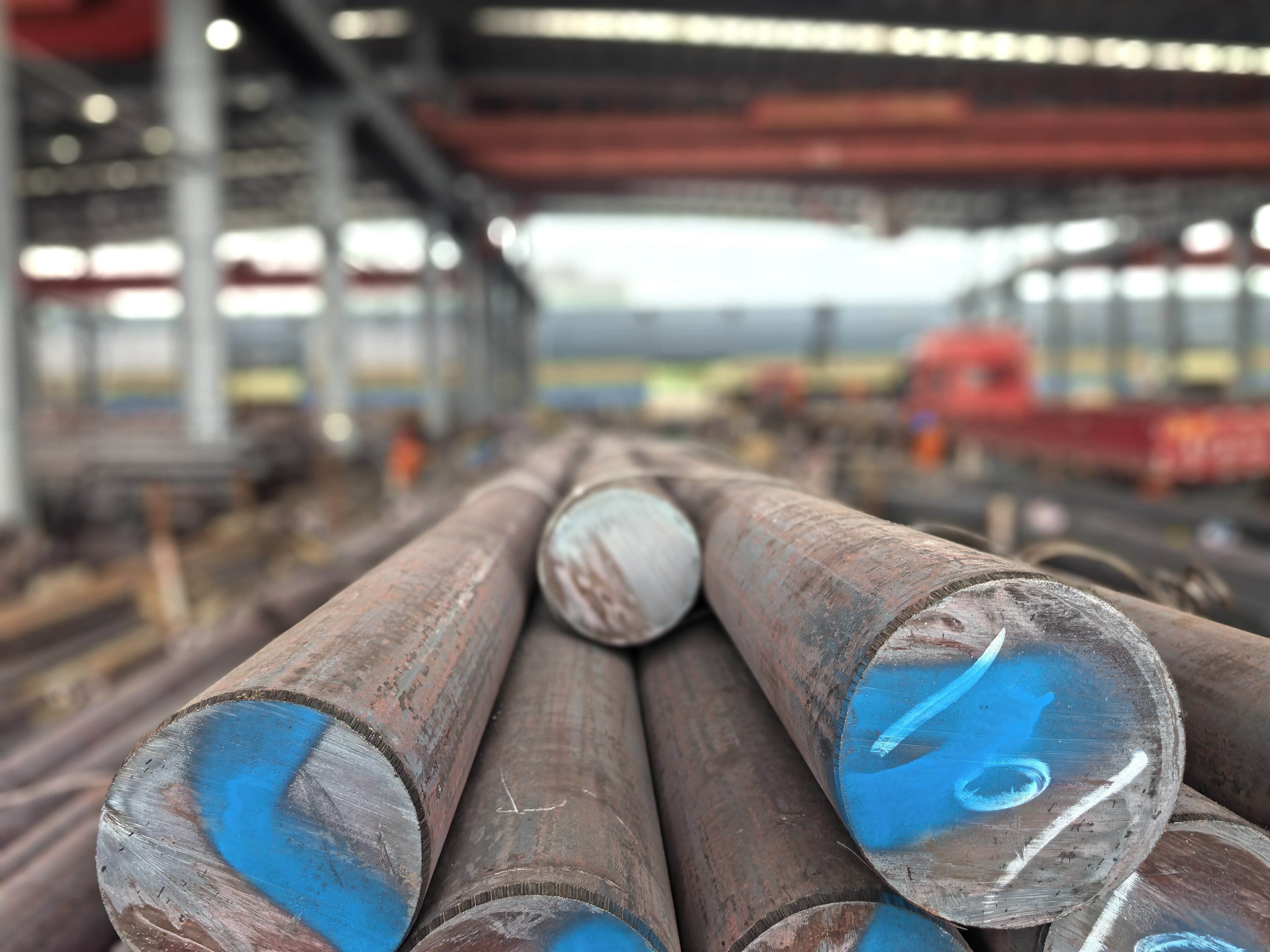

high speed steel lathe bits

High speed steel lathe bits represent a cornerstone technology in precision machining operations, delivering exceptional performance across diverse metalworking applications. These cutting tools are manufactured from high speed steel alloy, a specialized material composition that maintains its hardness and cutting edge integrity even at elevated temperatures generated during high-velocity machining processes. The primary function of high speed steel lathe bits involves removing material from workpieces through controlled cutting actions, shaping components to precise dimensional specifications while maintaining superior surface finishes. These tools excel in turning operations, facing cuts, threading applications, and complex contouring work on various metal substrates including steel, aluminum, brass, and cast iron materials. The technological features of high speed steel lathe bits include advanced metallurgical composition incorporating tungsten, molybdenum, vanadium, and cobalt elements that enhance wear resistance, thermal stability, and cutting performance. Modern manufacturing processes employ powder metallurgy techniques and specialized heat treatment protocols to optimize grain structure and achieve consistent material properties throughout the cutting tool geometry. The cutting edge geometry features precision-ground angles, including rake angles, relief angles, and cutting edge preparations that maximize chip evacuation efficiency while minimizing cutting forces and thermal generation. High speed steel lathe bits find extensive applications in production machining environments, maintenance workshops, educational institutions, and prototype development facilities. These tools prove particularly valuable in applications requiring frequent tool changes, interrupted cuts, or operations where tool breakage consequences are severe. The versatility of high speed steel lathe bits makes them suitable for both roughing operations that prioritize material removal rates and finishing passes that demand dimensional accuracy and surface quality. Their robust construction enables reliable performance in manual lathes, CNC turning centers, and specialized machining equipment across automotive, aerospace, general manufacturing, and repair industries.