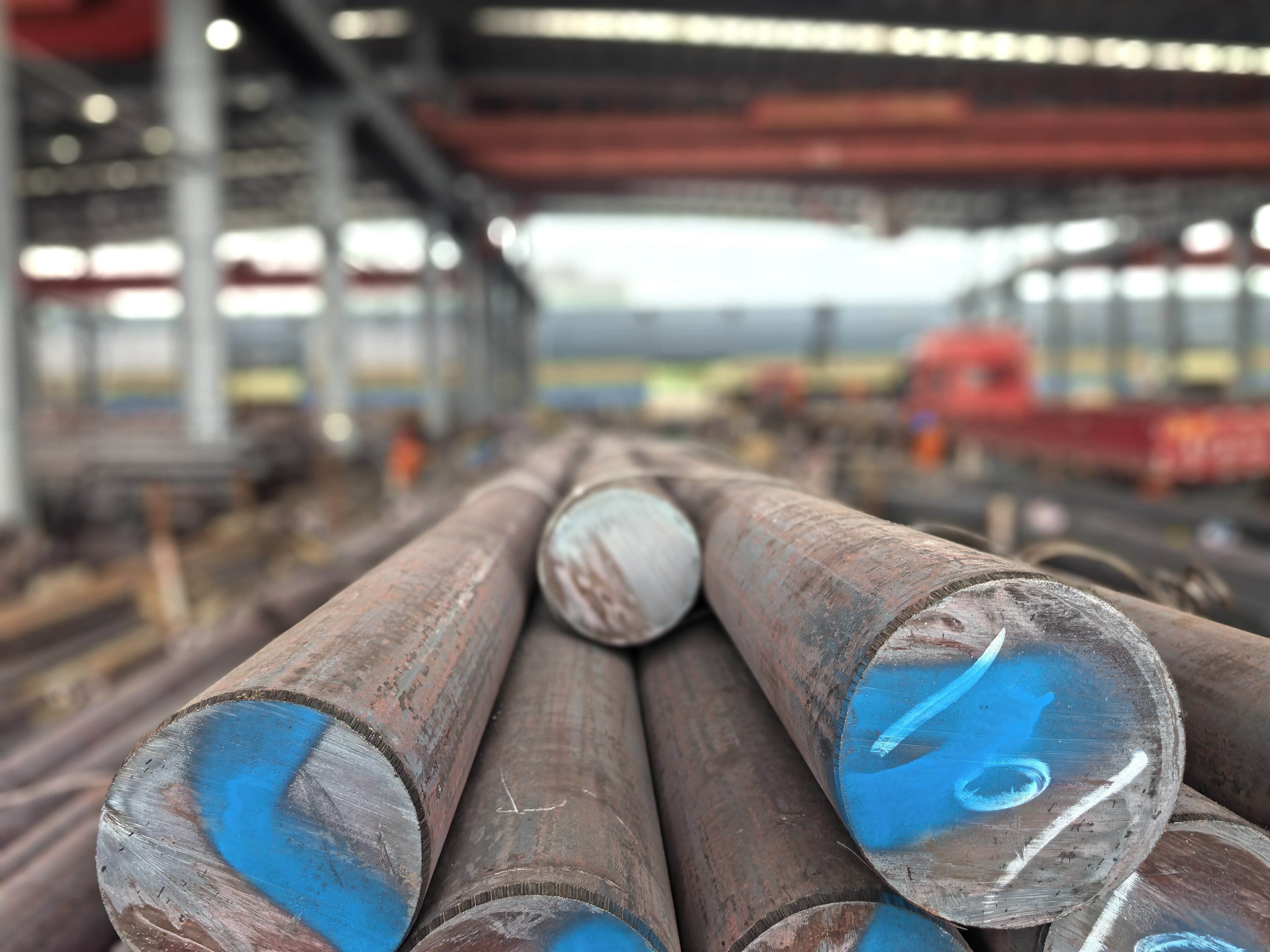

high speed steel bit

High speed steel bit represents a pinnacle of cutting tool engineering, designed to deliver exceptional performance in demanding machining applications. This specialized cutting tool combines advanced metallurgy with precision manufacturing to create a versatile solution for drilling, milling, and turning operations across various industries. The high speed steel bit incorporates a sophisticated alloy composition that typically includes tungsten, molybdenum, vanadium, and chromium, creating a material matrix that maintains its hardness and cutting edge retention even at elevated temperatures. These bits are manufactured through carefully controlled processes that include hot rolling, heat treatment, and precise tempering to achieve optimal grain structure and mechanical properties. The technological features of high speed steel bit include superior heat resistance, allowing continuous operation at temperatures up to 600 degrees Celsius without significant loss of hardness or cutting performance. The tool geometry is engineered with specific rake angles, relief angles, and cutting edge configurations that optimize chip formation and evacuation while minimizing cutting forces and vibration. Modern high speed steel bit designs incorporate specialized coatings such as titanium nitride or titanium aluminum nitride that further enhance wear resistance and reduce friction during cutting operations. Applications for high speed steel bit span numerous industries including automotive manufacturing, aerospace production, general machining, and precision engineering. These tools excel in machining ferrous and non-ferrous metals, plastics, and composite materials, making them indispensable in both production and prototype development environments. The versatility of high speed steel bit allows for use in conventional machine tools, CNC equipment, and portable drilling applications, providing consistent performance across different operational conditions and requirements.