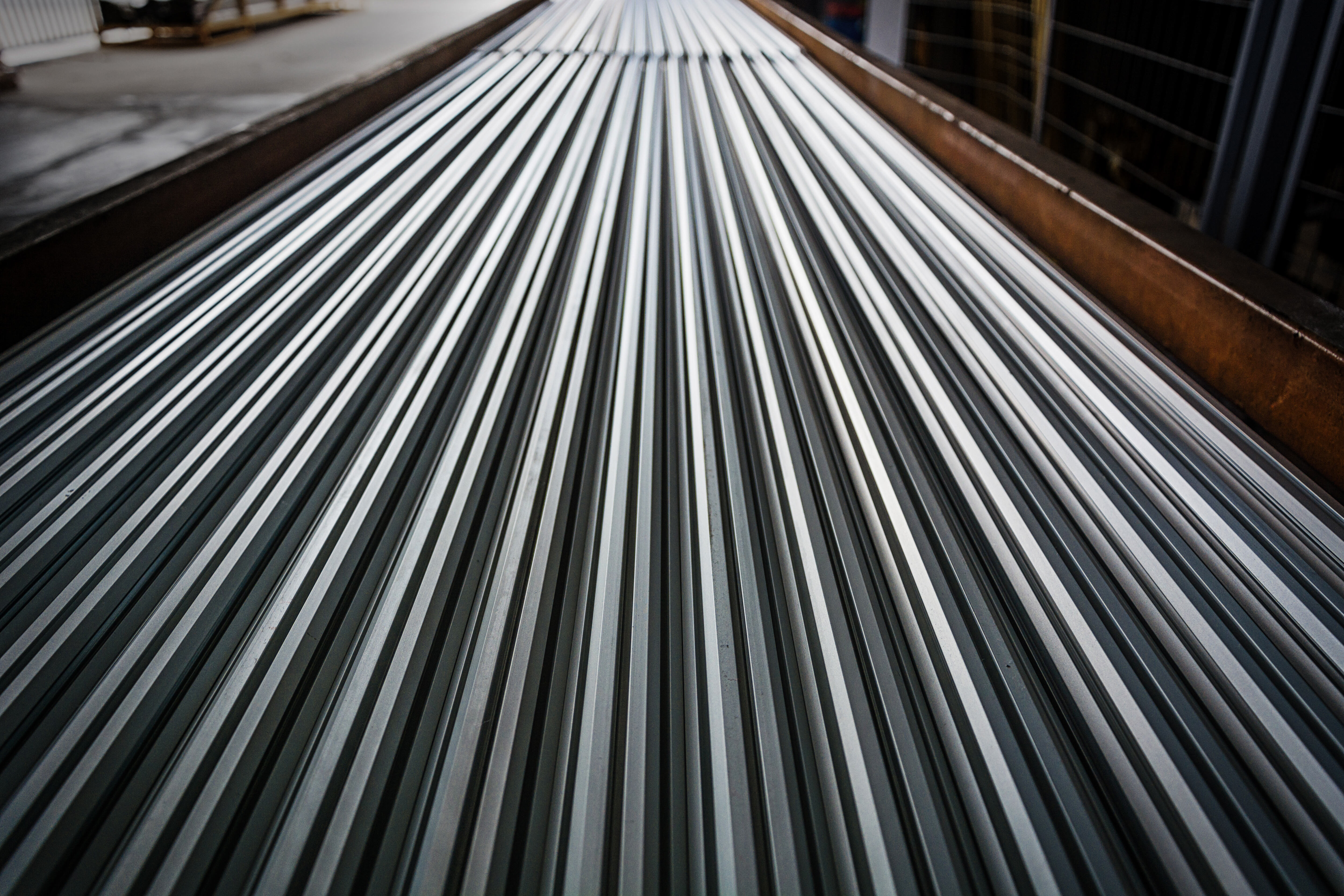

quality seamless steel pipe

Quality seamless steel pipe represents a pinnacle of manufacturing excellence in the steel industry, engineered through advanced production processes that eliminate welded joints entirely. This sophisticated piping solution is manufactured using the hot rolling or cold drawing method, where solid steel billets are heated and pierced to create hollow cylindrical structures without any seams or welds. The absence of welded joints distinguishes quality seamless steel pipe from traditional welded alternatives, providing superior structural integrity and performance characteristics. The main functions of quality seamless steel pipe encompass fluid transportation, structural support, and pressure containment across diverse industrial applications. These pipes excel in conveying liquids, gases, and other materials under high pressure conditions where reliability is paramount. The technological features of quality seamless steel pipe include exceptional wall thickness uniformity, precise dimensional accuracy, and consistent mechanical properties throughout the entire pipe length. Advanced manufacturing techniques ensure that each quality seamless steel pipe meets stringent international standards such as ASTM, API, and DIN specifications. The production process involves careful temperature control, precise sizing, and comprehensive quality testing to guarantee optimal performance. Applications for quality seamless steel pipe span numerous industries including oil and gas exploration, petrochemical processing, power generation, automotive manufacturing, and construction. In the energy sector, these pipes facilitate crude oil transportation, natural gas distribution, and refined product delivery systems. The automotive industry utilizes quality seamless steel pipe for exhaust systems, hydraulic lines, and structural components. Construction projects depend on these pipes for plumbing systems, HVAC installations, and architectural frameworks. The versatility of quality seamless steel pipe extends to specialized applications in aerospace, marine engineering, and industrial machinery where performance reliability cannot be compromised.