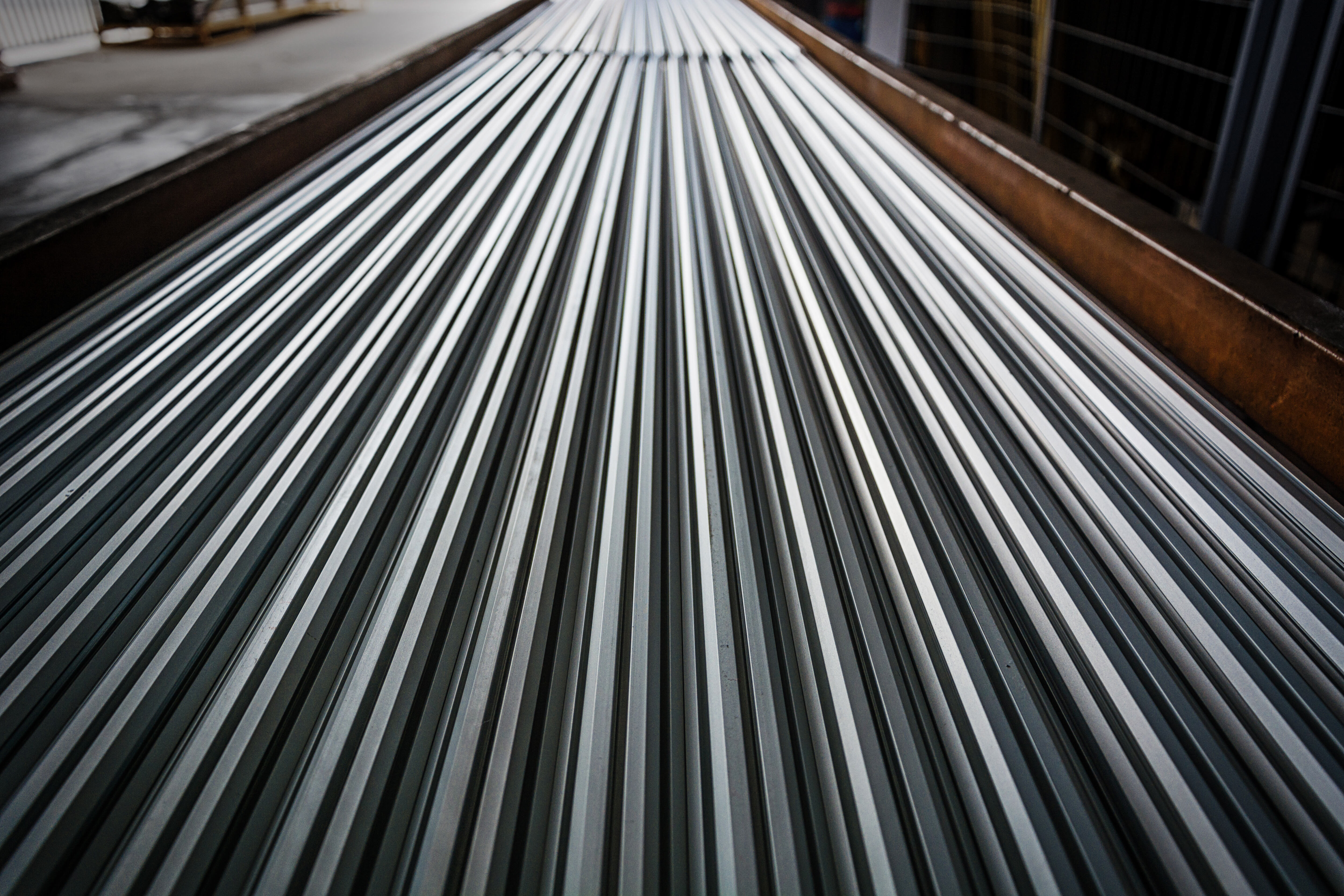

seamless alloy steel pipe

Seamless alloy steel pipe represents a pinnacle of engineering excellence in the manufacturing industry, combining advanced metallurgy with precision fabrication techniques. These specialized pipes are manufactured without any welded joints, utilizing a process that involves heating solid steel billets and then piercing them to create hollow cylindrical structures. The seamless alloy steel pipe incorporates various alloying elements such as chromium, molybdenum, nickel, and vanadium, which enhance its mechanical properties and corrosion resistance significantly beyond standard carbon steel alternatives. The primary function of seamless alloy steel pipe centers on transporting fluids and gases under extreme conditions where conventional piping materials would fail. These pipes excel in high-temperature environments, withstanding thermal stress that would compromise welded alternatives. The technological features of seamless alloy steel pipe include superior grain structure uniformity, enhanced tensile strength, and exceptional dimensional accuracy. The manufacturing process eliminates weak points typically found at welded seams, ensuring consistent performance throughout the entire pipe length. Applications for seamless alloy steel pipe span multiple industries including petroleum refining, chemical processing, power generation, and aerospace manufacturing. In oil and gas operations, these pipes serve critical roles in drilling operations, transporting crude oil, and handling refined petroleum products. The chemical industry relies on seamless alloy steel pipe for processing corrosive substances and maintaining product purity. Power plants utilize these pipes in boiler systems and steam distribution networks where high pressure and temperature conditions demand superior material performance. The aerospace sector employs seamless alloy steel pipe in hydraulic systems and structural applications where weight reduction and reliability are paramount concerns.