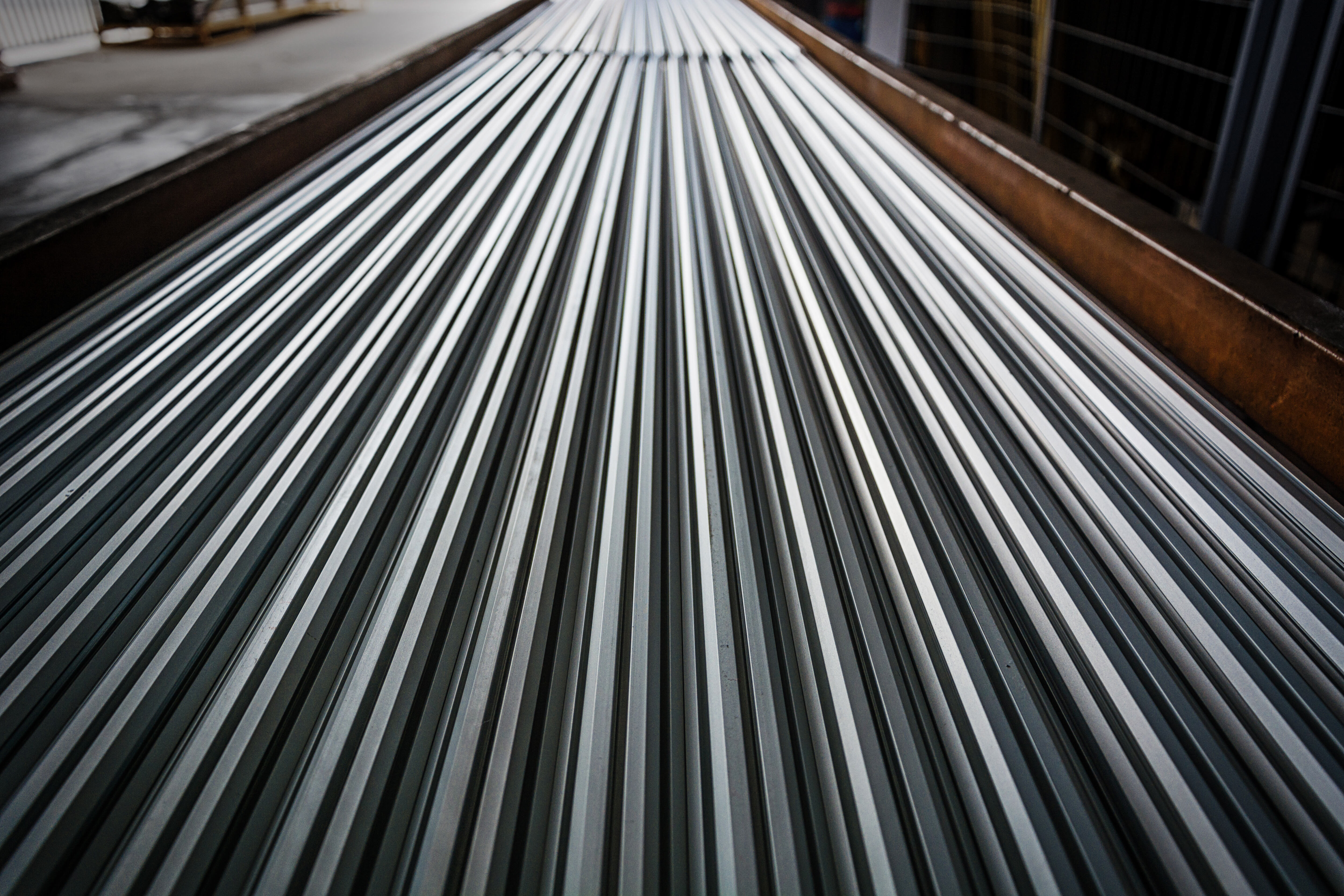

seamless tube pipe

Seamless tube pipe represents a revolutionary manufacturing achievement in the steel industry, created through a sophisticated production process that eliminates welded joints entirely. This manufacturing method involves piercing a solid steel billet and then expanding it into the desired diameter through hot rolling or cold drawing techniques. The resulting seamless tube pipe offers superior structural integrity compared to welded alternatives, making it an essential component across numerous industrial sectors. The absence of welded seams means there are no weak points along the pipe's circumference, ensuring consistent wall thickness and enhanced pressure resistance capabilities. Seamless tube pipe exhibits remarkable durability under extreme operating conditions, including high temperatures, corrosive environments, and substantial internal pressures. The manufacturing process allows for precise control over dimensional tolerances, surface finish quality, and mechanical properties, resulting in products that meet stringent industry specifications. These pipes serve critical functions in oil and gas transmission, where reliability cannot be compromised, chemical processing plants requiring corrosion resistance, power generation facilities demanding high-temperature performance, and automotive applications needing lightweight yet strong components. The technological features of seamless tube pipe include uniform grain structure throughout the material, enhanced fatigue resistance, superior burst strength, and excellent machinability for custom fabrication requirements. Advanced quality control measures during production ensure each seamless tube pipe meets international standards for chemical composition, mechanical properties, and dimensional accuracy, providing customers with confidence in product performance and longevity across diverse applications.