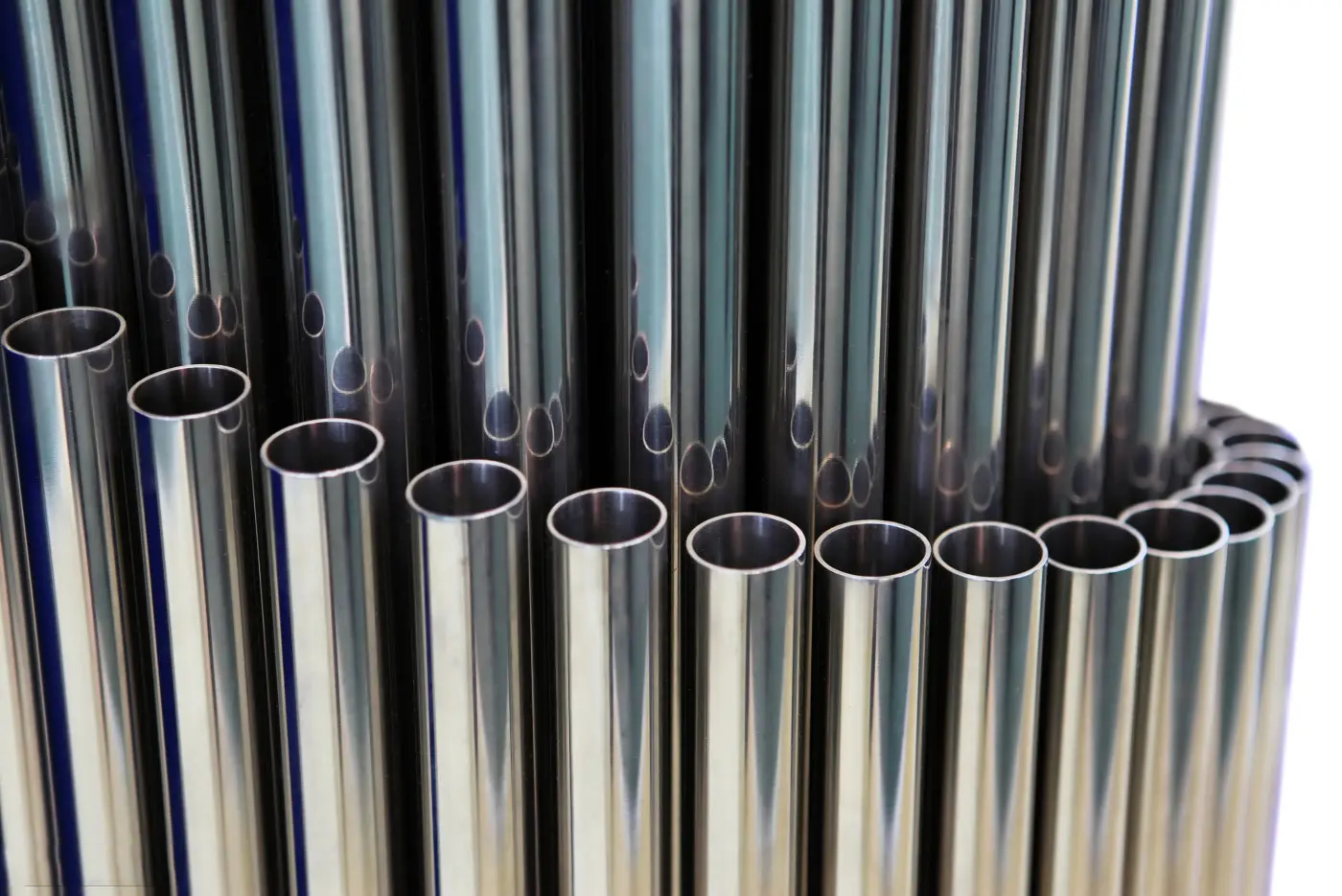

seamless pipes & tubes

Seamless pipes & tubes represent a critical manufacturing solution in modern industrial applications, characterized by their continuous construction without welded joints or seams. These products are manufactured through specialized processes that create a uniform, uninterrupted cylindrical structure from solid steel billets or bars. The absence of welded seams distinguishes seamless pipes & tubes from their welded counterparts, providing superior structural integrity and performance characteristics. The manufacturing process typically involves heating steel billets to extremely high temperatures, followed by piercing and rolling techniques that form the hollow interior while maintaining consistent wall thickness throughout the entire length. This sophisticated production method ensures that seamless pipes & tubes deliver exceptional strength, reliability, and durability across diverse operating conditions. The main functions of these products encompass fluid transportation, structural support, heat exchange applications, and pressure containment systems. Their technological features include uniform grain structure, enhanced corrosion resistance, superior pressure-bearing capacity, and excellent dimensional accuracy. The manufacturing precision achieved in seamless pipes & tubes ensures consistent internal diameter, wall thickness, and surface finish, making them ideal for critical applications where performance reliability is paramount. These products find extensive applications across multiple industries, including oil and gas exploration, petrochemical processing, power generation, automotive manufacturing, aerospace engineering, construction, and marine applications. The seamless construction eliminates potential weak points that could occur at welded joints, making these pipes and tubes particularly suitable for high-pressure, high-temperature, and corrosive environments where failure is not an option.