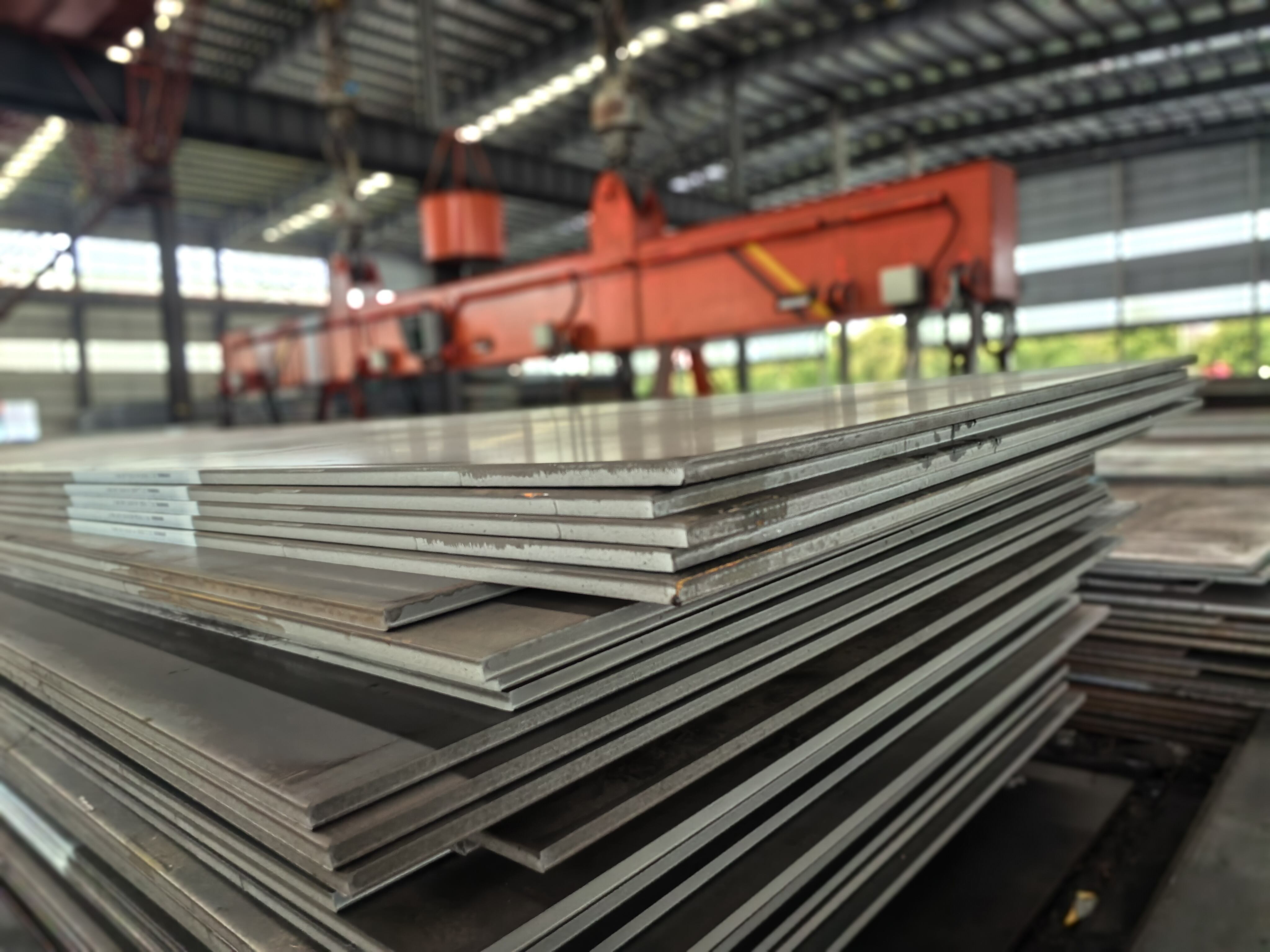

advanced high strength steel

Advanced high strength steel represents a revolutionary breakthrough in metallurgical engineering, combining exceptional mechanical properties with versatility across multiple industrial sectors. This cutting-edge material achieves tensile strengths ranging from 550 to 1500 MPa, significantly outperforming conventional steel grades while maintaining excellent formability and weldability characteristics. The primary function of advanced high strength steel centers on providing superior structural integrity in applications where weight reduction and enhanced performance are critical requirements. These materials incorporate sophisticated alloying elements and precise manufacturing processes to deliver optimal strength-to-weight ratios that meet demanding engineering specifications. The technological features of advanced high strength steel include microstructural refinement through controlled cooling processes, strategic addition of elements like manganese, silicon, and aluminum, and advanced thermomechanical processing techniques. These steels exhibit remarkable crash energy absorption capabilities, making them ideal for safety-critical components in automotive manufacturing. The material demonstrates excellent cold forming properties, allowing manufacturers to create complex geometries without compromising structural integrity. Heat treatment processes can further enhance mechanical properties, enabling customization for specific application requirements. Applications span across automotive body panels, chassis components, construction frameworks, energy infrastructure, and aerospace components. In automotive manufacturing, advanced high strength steel enables production of lighter vehicles with improved fuel efficiency while maintaining superior occupant protection during impact events. Construction industries utilize these materials for high-rise buildings, bridges, and offshore structures where environmental resistance and load-bearing capacity are paramount. The energy sector employs advanced high strength steel in wind turbine towers, oil drilling equipment, and pipeline systems. Manufacturing processes for advanced high strength steel incorporate precise temperature control, optimized chemical composition, and innovative rolling techniques. These materials support sustainable manufacturing practices by reducing material consumption while enhancing product durability and performance longevity across diverse industrial applications.