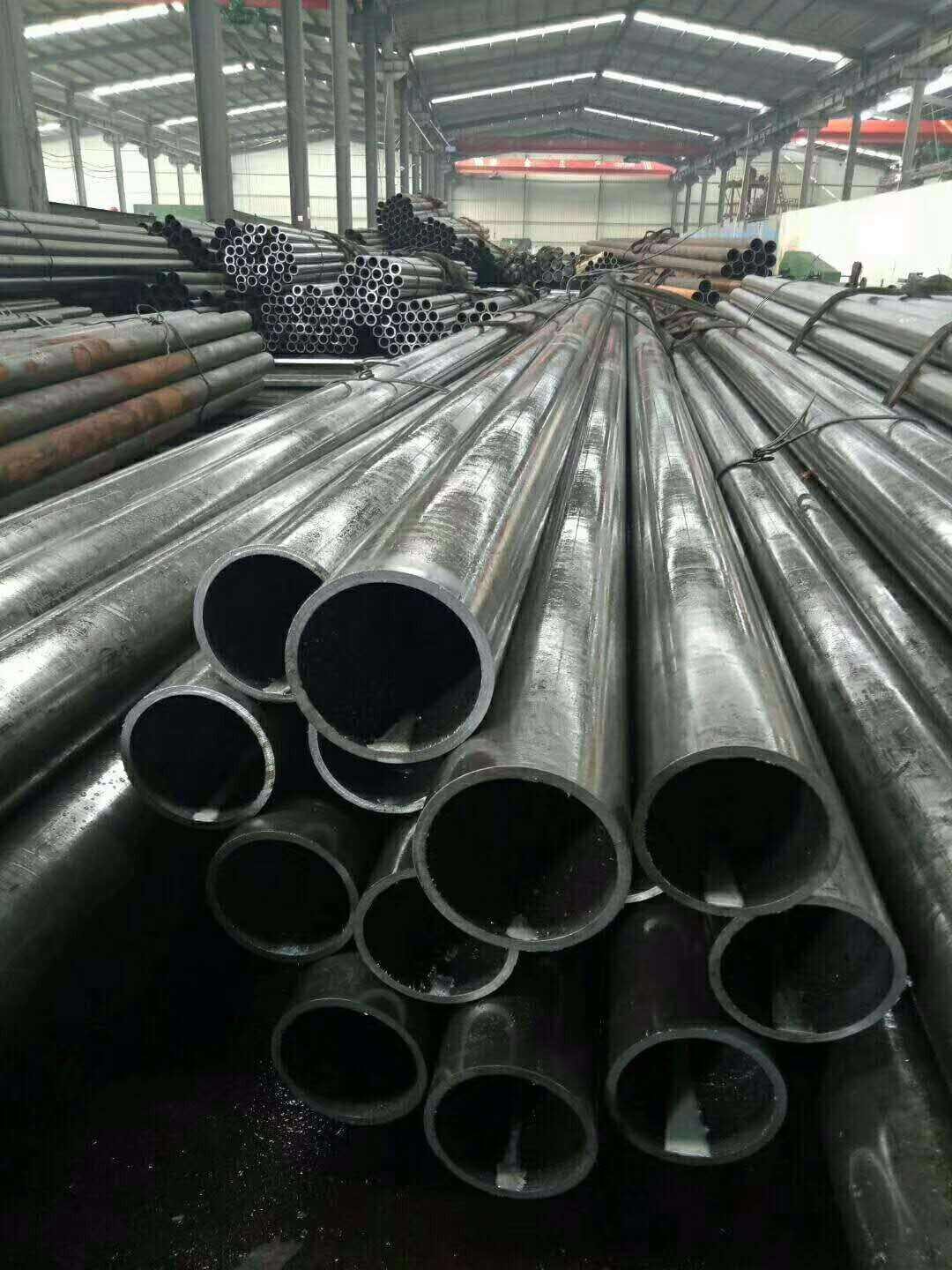

alloy steel pipe price

The alloy steel pipe price market represents a critical component of industrial infrastructure, where understanding cost factors directly impacts project budgeting and material selection decisions. Alloy steel pipes combine iron with various alloying elements such as chromium, nickel, molybdenum, and vanadium to enhance mechanical properties beyond those of standard carbon steel. The alloy steel pipe price fluctuates based on raw material costs, manufacturing complexity, and market demand, making it essential for buyers to understand pricing dynamics. These specialized pipes serve primary functions including high-temperature fluid transport, pressure vessel applications, and structural support in demanding environments. The technological features of alloy steel pipes include superior corrosion resistance, enhanced tensile strength, improved fatigue resistance, and excellent weldability characteristics. Manufacturing processes involve precise temperature control during forming, specialized heat treatment procedures, and rigorous quality testing protocols. The alloy steel pipe price reflects these advanced manufacturing requirements and superior material properties. Applications span across petroleum refining, chemical processing, power generation, aerospace manufacturing, and marine construction industries. In petrochemical facilities, these pipes handle corrosive substances and extreme temperatures where standard materials would fail. Power plants utilize alloy steel pipes for steam systems and high-pressure boiler applications. The aerospace industry depends on these materials for hydraulic systems and structural components requiring exceptional strength-to-weight ratios. Marine applications benefit from the corrosion resistance properties, particularly in saltwater environments. The alloy steel pipe price consideration becomes crucial when evaluating long-term operational costs versus initial investment. Quality grades range from low-alloy compositions suitable for moderate service conditions to high-alloy variants designed for extreme environments. Market factors influencing the alloy steel pipe price include global steel production capacity, energy costs, transportation expenses, and regulatory compliance requirements. Understanding these pricing elements enables informed procurement decisions that balance performance requirements with budget constraints.