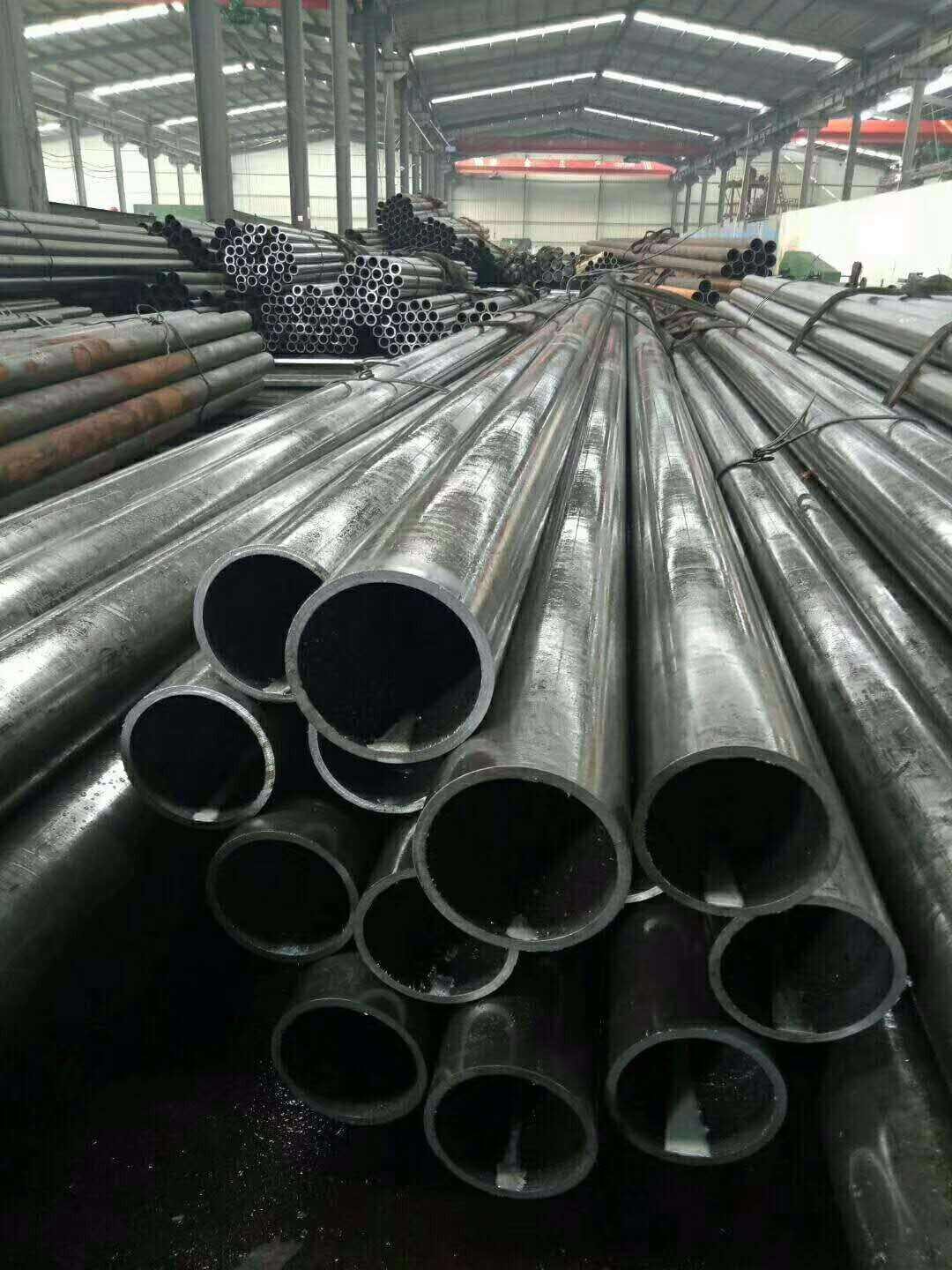

alloy steel tube

Alloy steel tube represents a sophisticated engineering solution that combines multiple metallic elements to create pipes with enhanced mechanical properties and performance characteristics. Unlike conventional carbon steel tubes, alloy steel tube incorporates precise quantities of chromium, molybdenum, nickel, vanadium, and other alloying elements that significantly improve strength, durability, and resistance to extreme operating conditions. The manufacturing process involves careful metallurgical control to ensure uniform distribution of these elements throughout the tube structure. The primary functions of alloy steel tube include fluid transportation in high-pressure systems, structural support in demanding environments, and heat transfer applications where standard materials would fail. These tubes excel in petroleum refining, chemical processing, power generation, and aerospace industries where reliability cannot be compromised. The technological features of alloy steel tube encompass superior tensile strength, enhanced corrosion resistance, improved high-temperature stability, and excellent fatigue resistance. Advanced manufacturing techniques such as seamless rolling, precision cold drawing, and specialized heat treatment processes ensure dimensional accuracy and consistent wall thickness. The microstructural refinement achieved through controlled cooling and tempering results in optimal grain structure that maximizes mechanical properties. Applications span across critical infrastructure including boiler systems, heat exchangers, hydraulic cylinders, automotive components, and offshore drilling equipment. The versatility of alloy steel tube makes it indispensable for transporting corrosive chemicals, high-pressure steam, and extreme temperature fluids. Quality control measures throughout production guarantee compliance with international standards such as ASTM, API, and DIN specifications. The precise chemical composition and mechanical testing ensure each alloy steel tube meets stringent performance requirements for specific industrial applications.