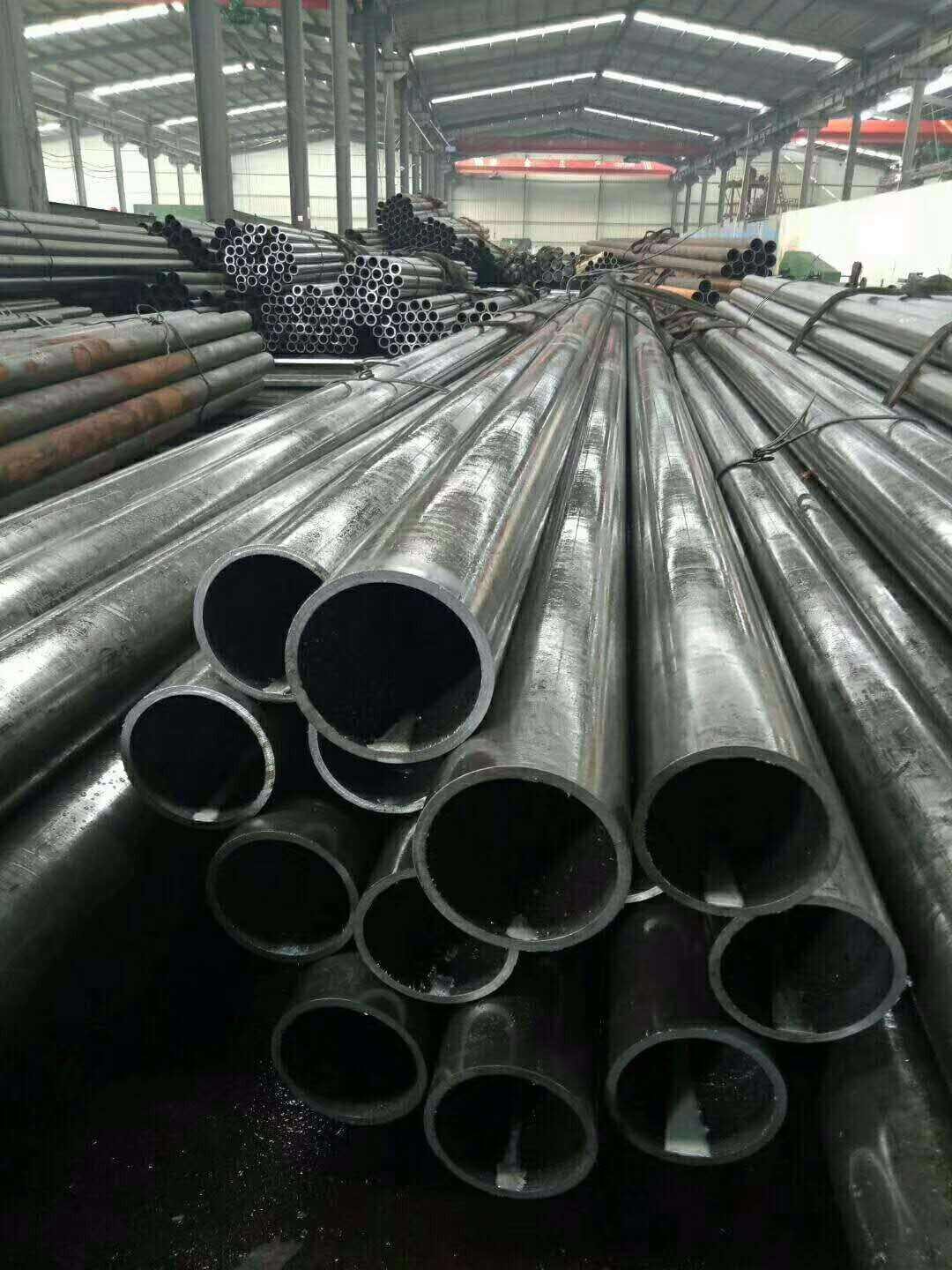

alloy steel pipe wholesale

Alloy steel pipe wholesale represents a crucial component in modern industrial infrastructure, offering superior performance characteristics that make it indispensable across numerous sectors. These specialized pipes are manufactured by combining iron with various alloying elements such as chromium, molybdenum, nickel, and vanadium, creating enhanced mechanical properties that surpass traditional carbon steel alternatives. The wholesale distribution of alloy steel pipe systems enables businesses to access high-quality piping solutions at competitive prices while maintaining consistent supply chains for large-scale projects. The main functions of alloy steel pipe wholesale operations include providing corrosion-resistant transportation systems for fluids, gases, and chemicals in demanding environments. These pipes excel in high-temperature applications, withstanding extreme thermal conditions that would compromise standard steel materials. The technological features of alloy steel pipe wholesale products encompass advanced metallurgical compositions that deliver exceptional tensile strength, improved ductility, and enhanced resistance to stress corrosion cracking. Manufacturing processes involve precise temperature control during formation, specialized heat treatment procedures, and rigorous quality testing protocols to ensure dimensional accuracy and material integrity. Applications for alloy steel pipe wholesale span across petroleum refineries, chemical processing plants, power generation facilities, aerospace manufacturing, automotive industries, and marine construction projects. The wholesale model provides significant value by offering bulk purchasing opportunities, customized sizing options, and comprehensive technical support services. Quality certifications and compliance with international standards such as ASTM, ASME, and API ensure reliability and safety in critical applications. The alloy steel pipe wholesale market continues expanding due to increasing demand for durable infrastructure solutions that can withstand harsh operating conditions while maintaining long-term performance reliability and cost-effectiveness.