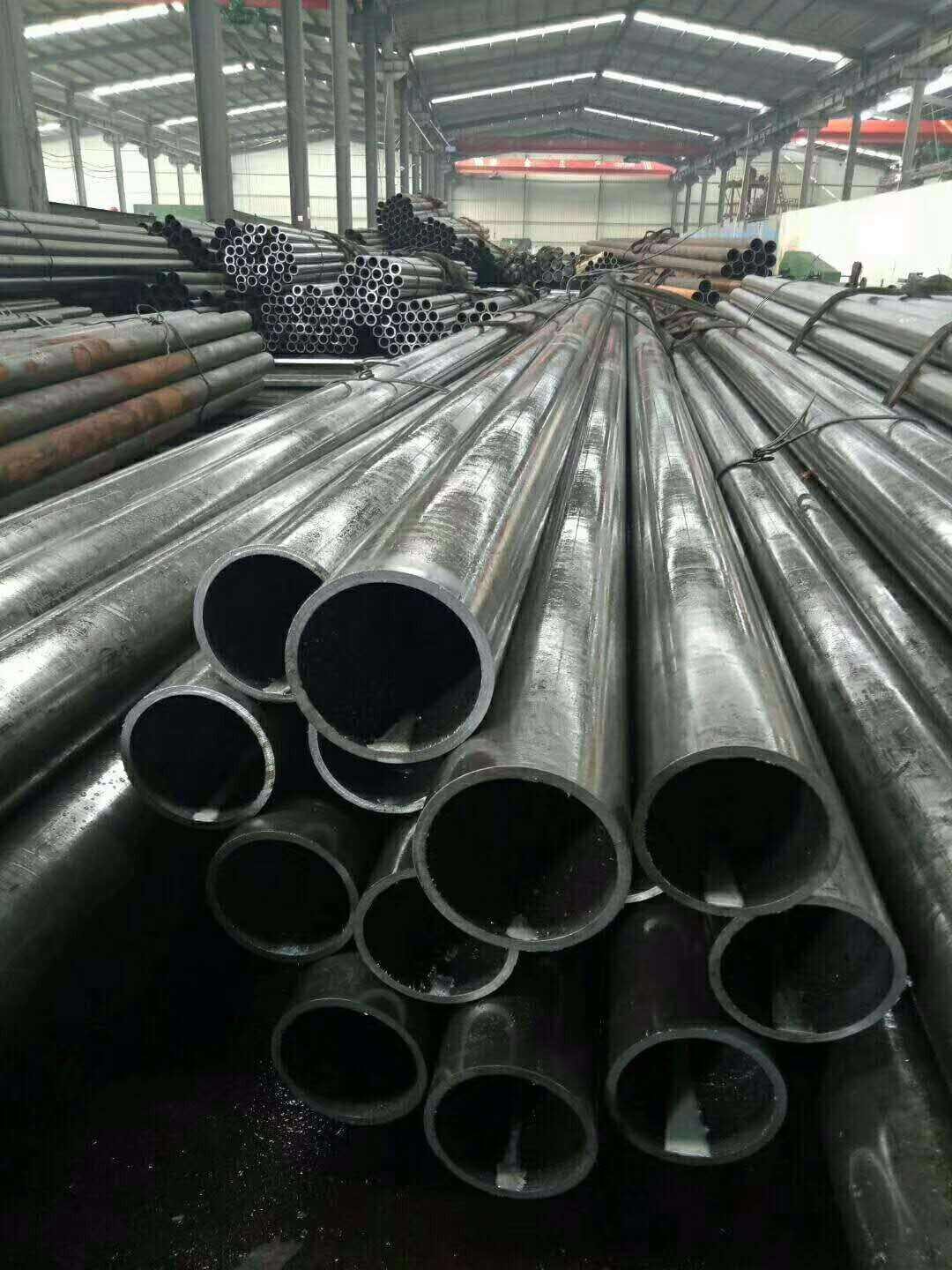

alloy steel pipe grades

Alloy steel pipe grades represent a sophisticated category of piping solutions engineered to meet demanding industrial requirements across multiple sectors. These specialized pipes incorporate various alloying elements including chromium, molybdenum, nickel, vanadium, and tungsten, which significantly enhance their mechanical properties beyond those of standard carbon steel pipes. The main function of alloy steel pipe grades centers on providing superior strength, corrosion resistance, and temperature stability in challenging operating environments. These pipes serve critical roles in high-pressure applications, extreme temperature conditions, and corrosive atmospheres where conventional materials would fail prematurely. Technologically, alloy steel pipe grades feature advanced metallurgical compositions that create unique microstructures through controlled heat treatment processes. The alloying elements form carbides and other intermetallic compounds that strengthen the steel matrix while maintaining ductility and toughness. Common grades include P11, P22, P91, and P911, each offering specific characteristics tailored to particular applications. Temperature resistance capabilities range from moderate heat applications to extreme high-temperature environments exceeding 600°C. The manufacturing process involves precise control of chemical composition, heat treatment cycles, and quality assurance protocols to ensure consistent performance. Applications for alloy steel pipe grades span numerous industries including power generation, petrochemical processing, oil and gas exploration, refineries, and chemical manufacturing. In power plants, these pipes handle superheated steam and high-pressure water systems. Petrochemical facilities utilize them for catalyst tubes, reformer applications, and high-temperature process lines. The oil and gas sector employs alloy steel pipe grades in drilling operations, wellhead equipment, and pipeline systems operating under extreme conditions. Their versatility extends to aerospace, automotive manufacturing, and specialized industrial processes where reliability and performance cannot be compromised.