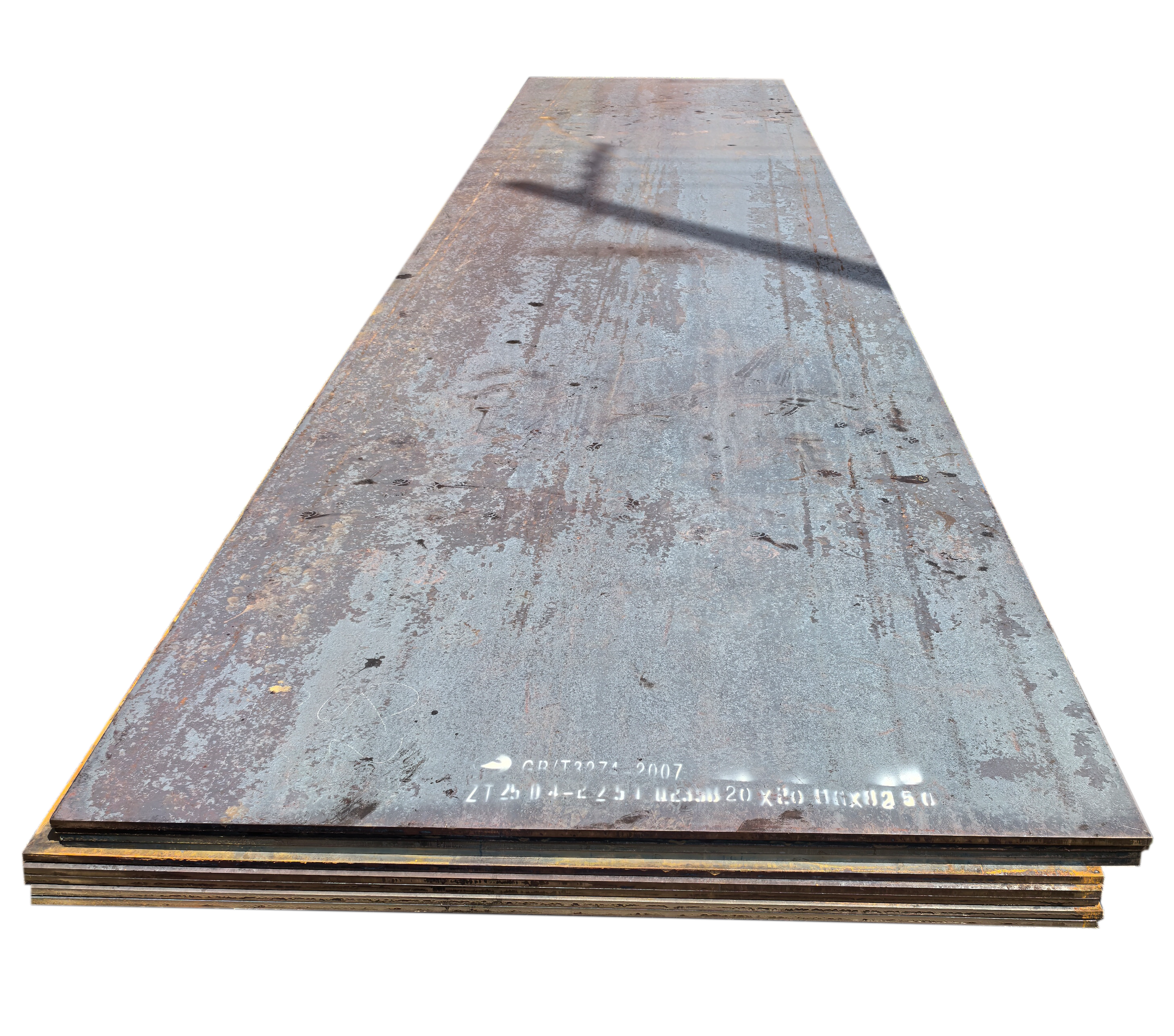

buy carbon steel

When you buy carbon steel, you invest in one of the most versatile and widely used materials in modern manufacturing and construction. Carbon steel represents a fundamental alloy composed primarily of iron and carbon, with carbon content typically ranging from 0.05% to 2.0%. This material serves as the backbone of countless industries due to its exceptional balance of strength, workability, and cost-effectiveness. The main functions of carbon steel encompass structural support, manufacturing components, tooling applications, and infrastructure development. Its technological features include excellent machinability, superior weldability, and remarkable formability that allows for complex shape creation through various manufacturing processes. The material exhibits outstanding tensile strength, making it ideal for load-bearing applications, while its ductility enables extensive forming operations without compromising structural integrity. Carbon steel applications span across automotive manufacturing, construction frameworks, pipeline systems, agricultural equipment, household appliances, and industrial machinery. In construction, when you buy carbon steel, you secure materials for building frames, reinforcement bars, and structural beams that form the skeleton of skyscrapers and bridges. The automotive industry relies heavily on carbon steel for body panels, chassis components, and engine parts due to its strength-to-weight ratio and manufacturing efficiency. Pipeline applications benefit from carbon steel's corrosion resistance when properly treated and its ability to withstand high-pressure environments. Agricultural sectors utilize carbon steel in farming equipment, storage silos, and processing machinery because of its durability and resistance to mechanical stress. The technological advancement in carbon steel production has led to improved grain structures, enhanced surface finishes, and better chemical compositions that meet specific application requirements. Heat treatment processes further expand carbon steel capabilities, allowing manufacturers to achieve desired hardness, toughness, and wear resistance properties through controlled heating and cooling cycles.