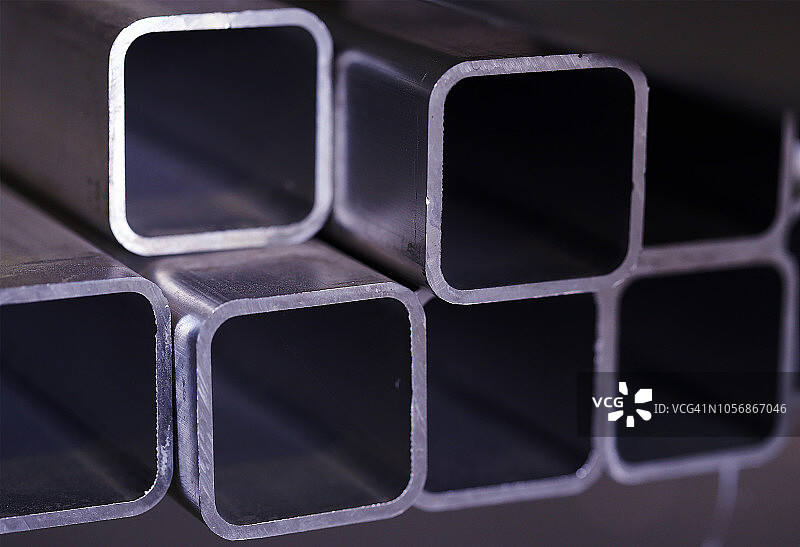

carbon steel manufacturer

A carbon steel manufacturer represents a specialized industrial entity that focuses on producing one of the most essential materials in modern construction and manufacturing sectors. These companies operate sophisticated production facilities equipped with advanced metallurgical technologies to create carbon steel products that meet stringent quality standards and diverse application requirements. The primary function of a carbon steel manufacturer involves the precise control of carbon content within steel compositions, typically ranging from 0.05% to 2.0%, which directly influences the material's mechanical properties, durability, and performance characteristics. Through carefully managed processes including melting, refining, casting, and rolling, these manufacturers transform raw materials into finished carbon steel products suitable for countless industrial applications. The technological features employed by leading carbon steel manufacturers include state-of-the-art electric arc furnaces, continuous casting systems, and precision rolling mills that ensure consistent product quality and dimensional accuracy. Advanced quality control laboratories conduct comprehensive testing procedures including chemical analysis, mechanical property evaluation, and non-destructive testing to guarantee that every batch meets specified standards. Modern carbon steel manufacturers utilize computer-controlled production systems that monitor temperature, composition, and processing parameters in real-time, enabling precise adjustments throughout the manufacturing cycle. Applications for carbon steel products span numerous industries including construction, automotive, shipbuilding, machinery manufacturing, and infrastructure development. In construction, carbon steel serves as reinforcement bars, structural beams, and sheet materials for buildings and bridges. The automotive industry relies on carbon steel for body panels, chassis components, and engine parts due to its excellent formability and strength-to-weight ratio. Shipbuilding applications utilize carbon steel plates and sections for hull construction, while machinery manufacturers depend on carbon steel for gears, shafts, and various mechanical components that require reliable performance under demanding operating conditions.