customized carbon steel

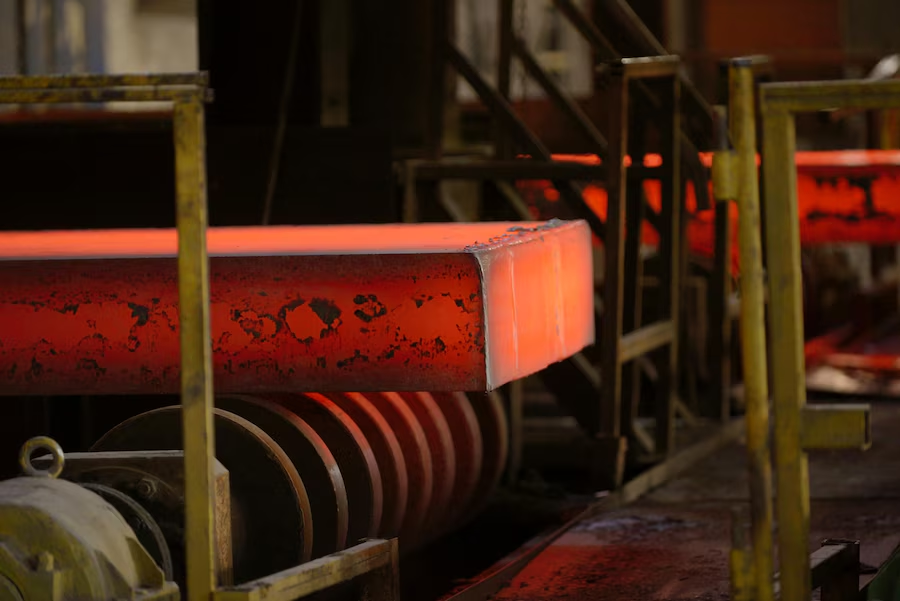

Customized carbon steel represents a revolutionary approach to material engineering, offering tailored solutions that meet specific industrial requirements while maintaining the fundamental strength and versatility of traditional carbon steel. This specialized material undergoes precise modifications in chemical composition, heat treatment processes, and mechanical properties to deliver optimal performance for unique applications. The customization process involves adjusting carbon content levels, incorporating specific alloying elements, and implementing targeted manufacturing techniques to achieve desired characteristics such as enhanced hardness, improved corrosion resistance, or superior machinability. Modern customized carbon steel production utilizes advanced metallurgical technologies including computer-controlled furnace operations, precise temperature monitoring systems, and sophisticated quality control measures that ensure consistent results across production batches. The material exhibits exceptional adaptability, allowing manufacturers to create variants that excel in extreme temperature conditions, high-stress environments, or specialized machining operations. Key technological features include controlled grain structure development, optimized chemical composition ratios, and strategic heat treatment protocols that enhance specific mechanical properties while maintaining structural integrity. The customization process enables precise control over tensile strength, yield strength, elongation characteristics, and impact resistance, making it possible to create materials that perfectly match application-specific requirements. Manufacturing facilities employ state-of-the-art equipment including vacuum induction melting systems, continuous casting technologies, and advanced rolling mills that ensure uniform material properties throughout the production process. Quality assurance protocols involve comprehensive testing procedures including mechanical property evaluation, chemical analysis, and microstructural examination to guarantee that each batch of customized carbon steel meets stringent performance standards and customer specifications.