best carbon steel

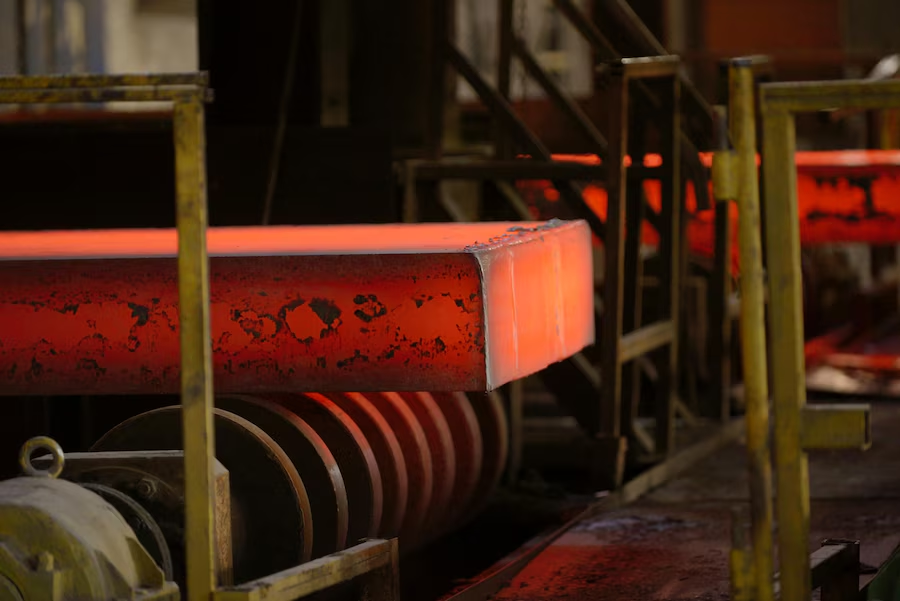

The best carbon steel represents a pinnacle of metallurgical engineering, combining exceptional performance characteristics with versatile applications across numerous industries. Carbon steel, fundamentally composed of iron and carbon, achieves its superior properties through precise carbon content control, typically ranging from 0.30% to 1.70%. This carefully balanced composition creates a material that delivers outstanding strength, durability, and workability. The best carbon steel grades undergo rigorous manufacturing processes, including controlled cooling, heat treatment, and quality testing to ensure consistent performance. These steels exhibit remarkable tensile strength, often exceeding 800 MPa, while maintaining excellent machinability and weldability. The technological features of premium carbon steel include fine grain structure, uniform carbon distribution, and minimal impurities, resulting in predictable mechanical properties and reliable performance. Modern production techniques employ advanced furnace technology, continuous casting, and precise rolling processes to achieve optimal microstructure. The best carbon steel finds extensive applications in automotive manufacturing, where it forms critical components like engine blocks, transmission parts, and structural frames. Construction industries rely on these steels for building frameworks, bridges, and infrastructure projects due to their exceptional load-bearing capabilities. Tool manufacturing represents another significant application area, where high-carbon variants create cutting tools, dies, and precision instruments. Agricultural equipment, machinery components, and marine applications also benefit from the corrosion resistance and mechanical properties of quality carbon steel. The versatility of the best carbon steel extends to knife manufacturing, where skilled craftsmen appreciate its ability to achieve razor-sharp edges while maintaining structural integrity. Railway applications utilize these steels for tracks, wheels, and structural components, demonstrating their ability to withstand extreme stress and environmental conditions.