Versatile Applications and Industry Integration

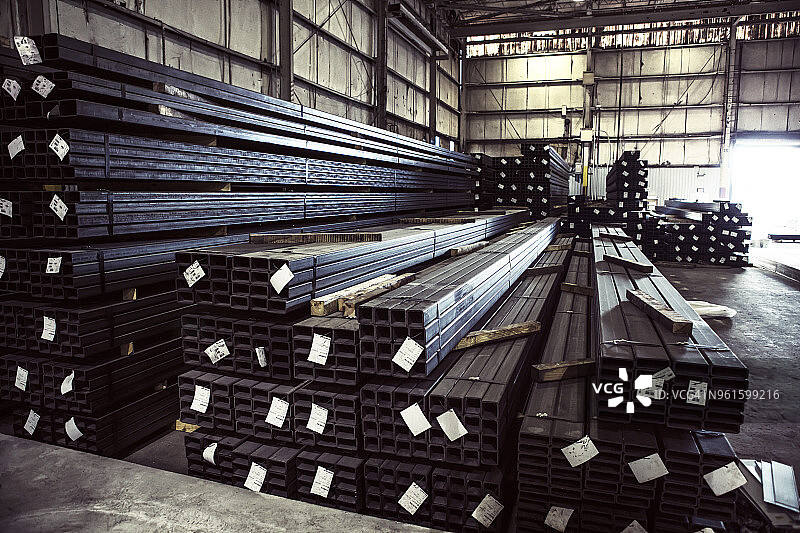

Cheap carbon steel demonstrates remarkable versatility across numerous industries and applications, establishing itself as the backbone material for countless products and structures worldwide. The construction industry relies heavily on cheap carbon steel for structural frameworks, reinforcement systems, and building components where its combination of strength, workability, and cost-effectiveness provides optimal solutions for modern infrastructure development. Residential construction utilizes cheap carbon steel in roofing materials, siding systems, and structural elements that require durability without premium pricing, enabling affordable housing development and renovation projects. Commercial construction projects benefit from standardized cheap carbon steel profiles and shapes that simplify design processes, reduce engineering complexity, and ensure consistent availability throughout project timelines. The automotive industry integrates cheap carbon steel extensively in body panels, chassis components, and internal structures where weight considerations balance against cost requirements and manufacturing efficiency. Agricultural applications showcase the adaptability of cheap carbon steel in equipment manufacturing, from tillage implements to harvesting machinery, where exposure to soil abrasion and weather conditions demands reliable performance at reasonable costs. Marine applications utilize cheap carbon steel in non-critical hull sections, internal framing, and deck structures where corrosion protection through coatings provides adequate service life at significantly lower material costs compared to marine-grade alloys. Manufacturing industries employ cheap carbon steel for machine bases, support structures, and tooling applications where dimensional stability and vibration damping characteristics enhance production quality and equipment performance. Pipeline and infrastructure projects rely on cheap carbon steel for water distribution systems, structural supports, and utility installations where long-term reliability combines with economic feasibility to support community development initiatives. The material adapts readily to specialized requirements through heat treatment, surface coating, and mechanical processing that customize properties for specific applications while maintaining the fundamental cost advantages that make projects economically viable.