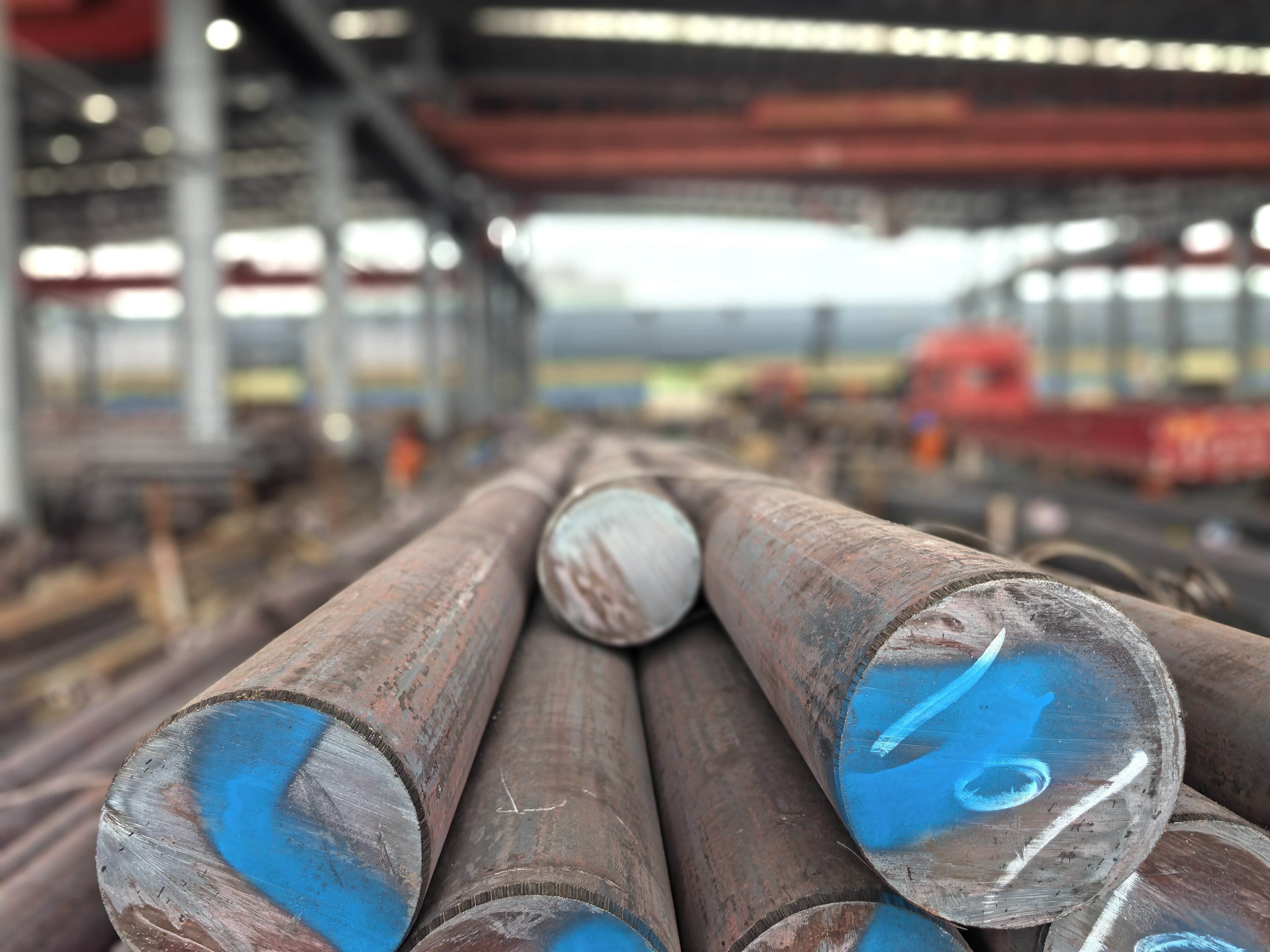

high speed steel turning tools

High speed steel turning tools represent a cornerstone technology in modern machining operations, delivering exceptional performance across diverse manufacturing applications. These cutting tools are manufactured from high speed steel (HSS), an advanced alloy containing tungsten, molybdenum, chromium, and vanadium elements that create superior hardness and heat resistance properties. The primary function of high speed steel turning tools involves removing material from workpieces through controlled cutting operations, enabling precise dimensional accuracy and surface finish quality. These tools excel in shaping cylindrical components, creating threads, and performing complex contouring operations on lathes and turning centers. The technological features of high speed steel turning tools include remarkable wear resistance, excellent toughness, and the ability to maintain sharp cutting edges under high-temperature conditions. The metallurgical composition allows these tools to retain their hardness even when operating temperatures reach 600 degrees Celsius, significantly higher than conventional carbon steel alternatives. High speed steel turning tools demonstrate versatility across multiple material types, effectively machining steel, cast iron, aluminum, brass, and various exotic alloys. Manufacturing industries rely on these tools for production operations ranging from automotive component fabrication to aerospace part manufacturing. The tools feature precise geometry control, enabling manufacturers to achieve tight tolerances and consistent surface finishes. Advanced coating technologies further enhance performance by reducing friction and extending tool life. High speed steel turning tools accommodate both rough machining operations that remove large amounts of material quickly and finish machining processes that achieve final dimensional specifications. Their robust construction withstands intermittent cutting forces and thermal cycling, making them ideal for interrupted cuts and challenging machining conditions. The economic benefits include reduced tool changeover frequency and improved productivity through faster cutting speeds and enhanced reliability in demanding production environments.