high temperature nickel alloys

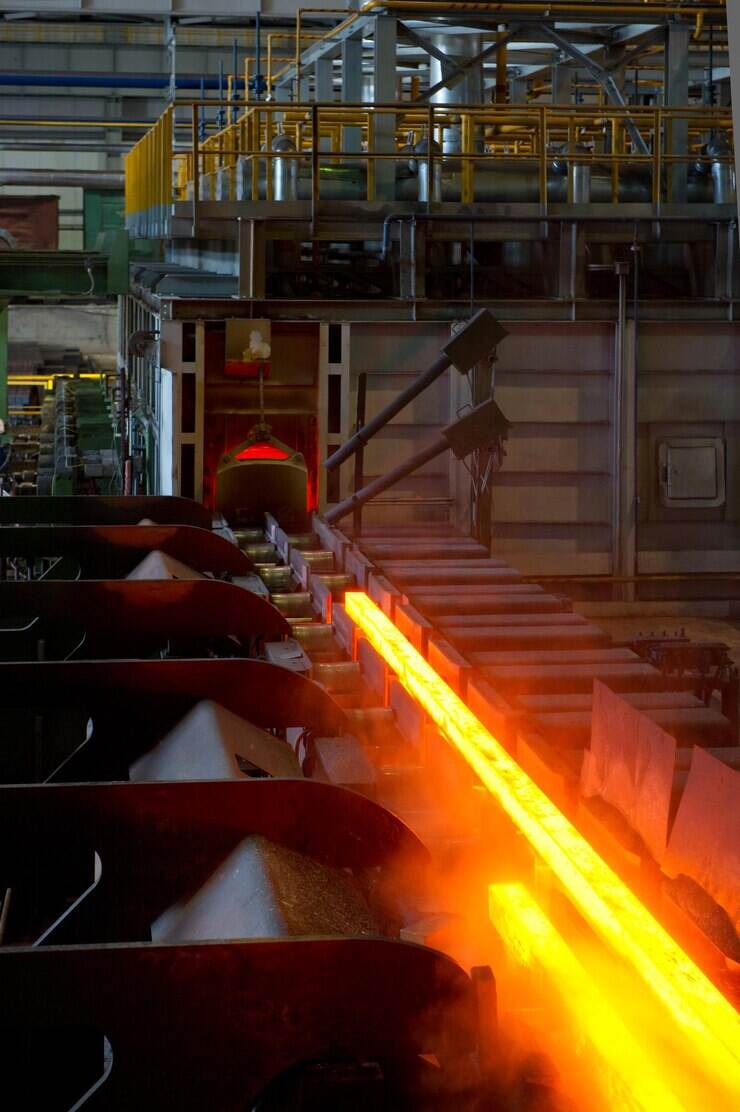

High temperature nickel alloys represent a pinnacle of metallurgical engineering, designed to withstand extreme thermal conditions while maintaining structural integrity and performance. These specialized materials combine nickel as the base element with carefully selected alloying additions including chromium, cobalt, molybdenum, tungsten, and aluminum to create exceptional heat-resistant properties. The primary function of high temperature nickel alloys centers on their ability to operate reliably in environments where temperatures exceed 1000°F (538°C), making them indispensable for critical applications across multiple industries. These alloys demonstrate remarkable resistance to oxidation, corrosion, and thermal fatigue, ensuring long-term durability under challenging conditions. The technological features of high temperature nickel alloys include superior creep resistance, which prevents deformation under sustained high-temperature stress, and excellent thermal stability that maintains mechanical properties even during prolonged exposure to extreme heat. Their microstructural design incorporates precipitate hardening mechanisms that strengthen the material matrix, while solid solution strengthening enhances overall performance characteristics. High temperature nickel alloys find extensive applications in aerospace propulsion systems, where they form critical components of jet engines including turbine blades, combustor liners, and exhaust systems. Power generation facilities utilize these materials for steam turbines, heat exchangers, and furnace components that must endure continuous high-temperature operation. Chemical processing industries depend on high temperature nickel alloys for reactor vessels, catalyst supports, and piping systems exposed to corrosive high-temperature environments. Additionally, these materials serve essential roles in automotive turbocharger components, industrial furnaces, and petrochemical refining equipment. The unique combination of thermal resistance, mechanical strength, and chemical stability makes high temperature nickel alloys the preferred choice for applications demanding reliable performance in extreme thermal environments where conventional materials would fail.