low price high temperature alloys

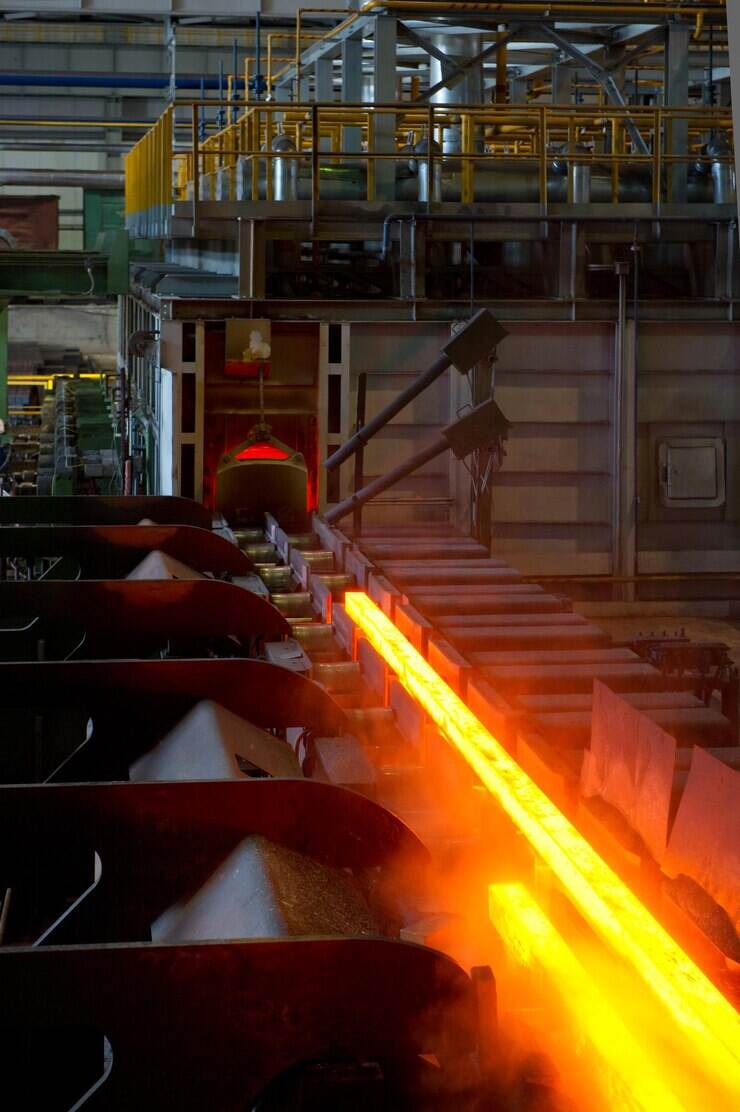

Low price high temperature alloys represent a revolutionary advancement in metallurgical engineering, offering exceptional performance characteristics at significantly reduced costs compared to traditional premium superalloys. These specialized metallic compositions are engineered to maintain structural integrity, mechanical strength, and corrosion resistance under extreme thermal conditions while remaining economically viable for widespread industrial applications. The primary function of low price high temperature alloys centers on providing reliable material solutions for environments where temperatures exceed 500°C, making them indispensable in power generation, aerospace manufacturing, automotive systems, and industrial processing equipment. Technologically, these alloys incorporate carefully balanced compositions of base metals such as nickel, iron, and chromium, enhanced with strategic additions of aluminum, titanium, and other alloying elements. This precise formulation creates a microstructure that exhibits excellent oxidation resistance, thermal fatigue resistance, and creep strength while maintaining cost-effectiveness through optimized material usage and streamlined manufacturing processes. The applications for low price high temperature alloys span numerous critical industries, including gas turbine components, heat exchangers, exhaust systems, furnace construction, petrochemical processing equipment, and power plant infrastructure. Manufacturing technologies employed in producing these alloys utilize advanced melting techniques, controlled atmosphere processing, and precision casting methods to ensure consistent quality and performance characteristics. The alloys demonstrate superior thermal stability through their ability to resist phase transformations and maintain mechanical properties at elevated temperatures, while their corrosion resistance stems from the formation of protective oxide layers that prevent degradation in harsh environments.